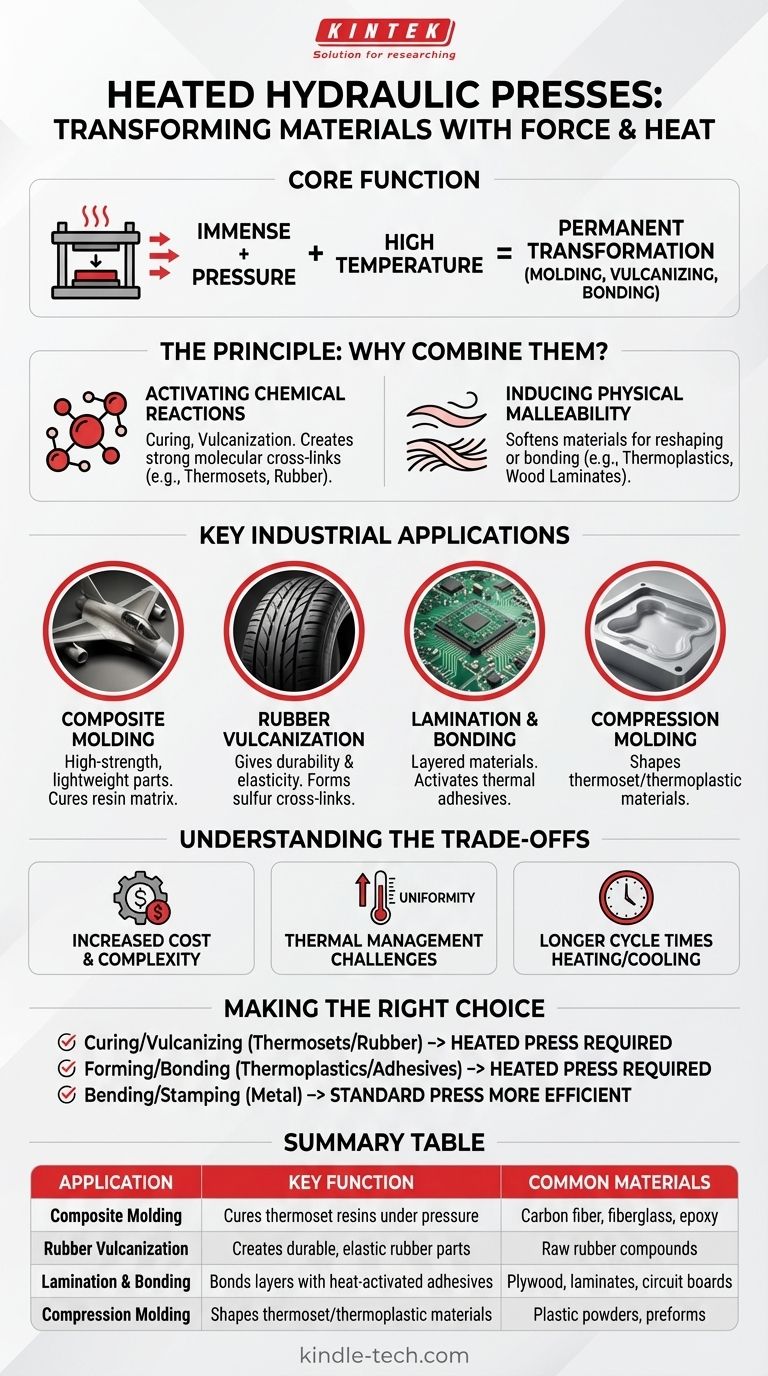

At its core, a heated hydraulic press is used for industrial processes where both immense pressure and high temperature are required to permanently change a material's shape, composition, or properties. Unlike standard presses that only apply force, heated presses add thermal energy to mold composites, vulcanize rubber, and bond layers of materials together.

The fundamental purpose of adding heat to a hydraulic press is to make materials either chemically reactive or physically malleable. The press's force then shapes or bonds the material while it is in this altered state, resulting in a permanent transformation that would be impossible with pressure alone.

The Principle: Why Combine Pressure and Heat?

Applying force is only half of the equation for many advanced materials. Heat acts as a catalyst, unlocking properties and enabling processes that cold pressing cannot achieve.

Activating Chemical Reactions

For materials like thermoset composites (e.g., carbon fiber with epoxy) or rubber, heat is not just for softening. It initiates an irreversible chemical reaction.

This process, known as curing or vulcanization, creates strong molecular cross-links within the material. The hydraulic pressure ensures the material conforms perfectly to the mold and eliminates voids during this reaction.

Inducing Physical Malleability

For other materials, like thermoplastics or wood laminates, heat makes them soft and pliable.

The high temperature allows the internal polymer chains or fibers to slide past one another. The press then applies force to reshape the material or activate a heat-sensitive adhesive, and the material retains its new form upon cooling.

Key Industrial Applications of Heated Presses

The combination of heat and pressure is critical in several high-value manufacturing sectors. Each application leverages the same core principle for a different outcome.

Composite Molding

Heated presses are essential for manufacturing high-strength, lightweight composite parts for the aerospace, automotive, and military industries.

The press heats platens to a precise temperature, which activates the resin matrix (like epoxy) surrounding fibers (like carbon or glass). The pressure compacts the layers and forces the resin to flow, ensuring a dense, strong, and perfectly shaped final part.

Rubber Vulcanization

This process gives rubber its durability, elasticity, and strength. A heated press applies pressure to raw rubber in a mold.

The heat initiates the vulcanization process, forming sulfur cross-links between polymer chains. The pressure ensures the final product, such as a gasket or tire tread, has a uniform density and precise dimensions.

Lamination and Bonding

Heated presses are widely used to create layered materials, from plywood and decorative laminates to circuit boards.

In this application, layers of material (wood, paper, fiberglass) are coated with a thermal-activated adhesive. The heated platens melt the adhesive while the press applies uniform pressure, creating a permanent, delamination-resistant bond across the entire surface.

Compression Molding

This is a primary method for shaping both thermoset and thermoplastic materials.

A pre-measured amount of molding material, often a powder or preform, is placed into a heated mold cavity. The press closes, and the combination of heat and pressure melts the material and forces it to fill the mold's shape before it is cured or cooled.

Understanding the Trade-offs

While powerful, heated presses introduce complexities not found in standard cold-press systems.

Increased Cost and Complexity

The addition of heating systems, whether through electric cartridges or circulating thermal oil, increases the initial purchase price and ongoing maintenance requirements of the press.

Thermal Management Challenges

Achieving and maintaining a perfectly uniform temperature across the entire surface of large platens is a significant engineering challenge. Any "cold spots" can result in an improperly cured or bonded product, leading to quality control failures.

Longer Cycle Times

Processes involving heat require time for the platens to heat up, for the heat to transfer to the material, and for the part to cool sufficiently before it can be safely removed. This makes cycle times inherently longer than simple stamping or bending operations.

Making the Right Choice for Your Material

Selecting the correct process depends entirely on the material you are working with and your desired outcome.

- If your primary focus is curing thermoset composites or vulcanizing rubber: A heated press is non-negotiable, as the chemical reaction is thermally driven.

- If your primary focus is forming thermoplastics or bonding with thermal adhesives: A heated press is required to make the material pliable or activate the bonding agent.

- If your primary focus is simply bending, stamping, or assembling metal parts: A standard (cold) hydraulic press is typically the more efficient and cost-effective tool.

Ultimately, a heated hydraulic press is the definitive tool for transforming materials by strategically combining force with thermal energy.

Summary Table:

| Application | Key Function | Common Materials |

|---|---|---|

| Composite Molding | Cures thermoset resins under pressure | Carbon fiber, fiberglass, epoxy |

| Rubber Vulcanization | Creates durable, elastic rubber parts | Raw rubber compounds |

| Lamination & Bonding | Bonds layers with heat-activated adhesives | Plywood, laminates, circuit boards |

| Compression Molding | Shapes thermoset/thermoplastic materials | Plastic powders, preforms |

Ready to transform your materials with precision heat and pressure?

KINTEK specializes in high-performance lab equipment and industrial solutions. Our expertise in heated hydraulic press technology can help you achieve superior results in composite molding, rubber vulcanization, and material bonding.

Contact us today to discuss your specific application needs and discover how our solutions can enhance your manufacturing process.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

People Also Ask

- Why is a high-tonnage laboratory hydraulic press required for hot-pressing TlBr? Optimize Your Radiation Detectors

- How does 40 MPa uniaxial pressure promote TaC densification? Enhance Tantalum Carbide Performance with Hot Pressing

- What are the different types of press machines? Choose the Right Heating Tech for Your Application

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- What is hot press molding? A Guide to High-Strength Manufacturing with Heat & Pressure

- What are the advantages of using a laboratory hydraulic press for hot pressing? Achieve Peak Nano-Composite Density

- Do I need a heat press machine? Unlock Professional, Durable Custom Apparel