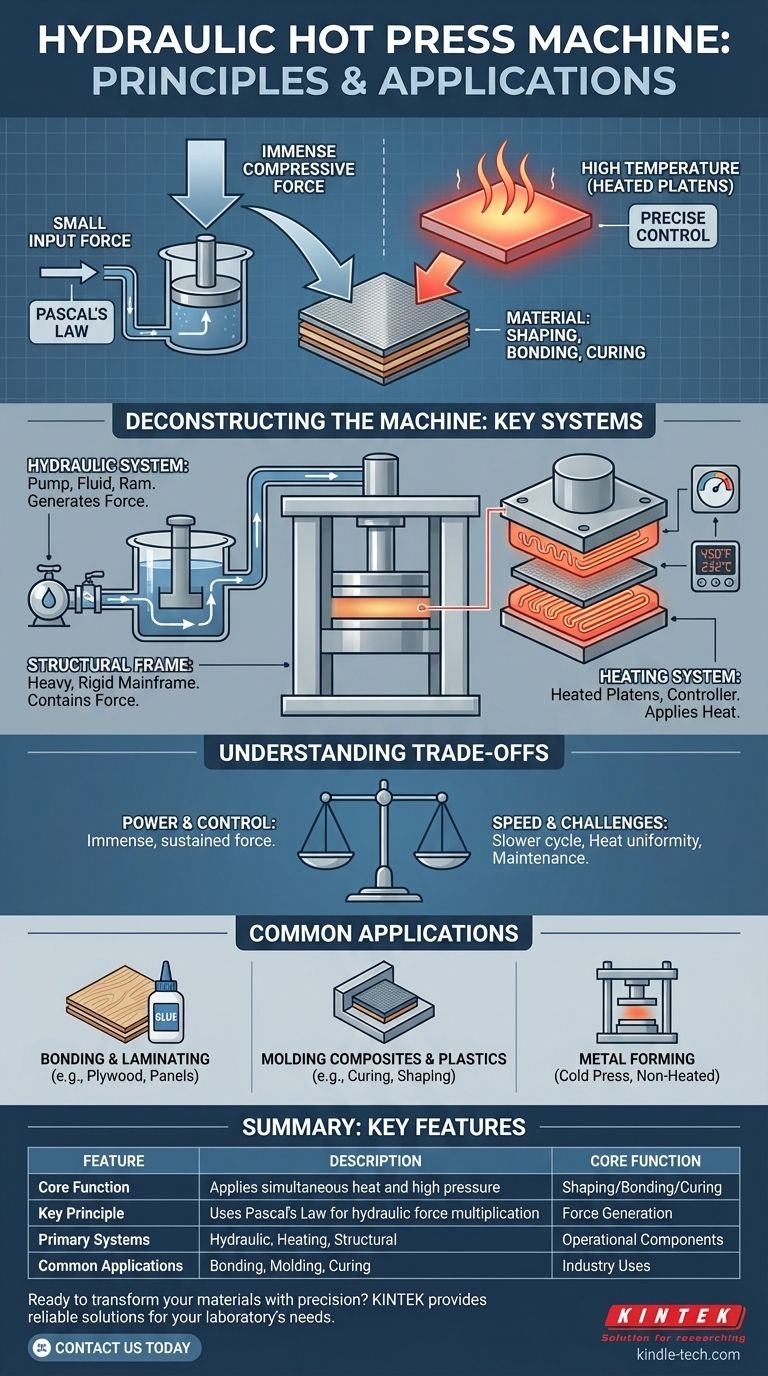

At its core, a hydraulic hot press is a machine that applies two forces simultaneously: immense compressive force and high temperature. It uses a liquid-based hydraulic system to generate significant pressure between heated plates, known as platens. This dual-action capability makes it essential for processes that require materials to be shaped, bonded, or cured under both heat and pressure.

A hydraulic hot press combines the force-multiplying power of hydraulics with a precisely controlled heating system. The machine's purpose isn't just to press something flat; it's to fundamentally change a material's properties by applying both mechanical and thermal energy at the same time.

The Core Principle: Force Multiplication

The "hydraulic" part of the name refers to how the machine generates its incredible force. The entire system is built upon a fundamental principle of fluid dynamics.

Pascal's Law in Action

A hydraulic press operates on Pascal's Law. This law states that pressure applied to an enclosed, incompressible fluid (like oil) is transmitted equally throughout that fluid.

Imagine a sealed system with two pistons of different sizes. Because the pressure is the same everywhere in the fluid, the force exerted by each piston is directly proportional to its surface area (Force = Pressure x Area).

From Small Force to Large Force

This is the key to force multiplication. A small amount of force applied to a small piston (the plunger) generates a specific pressure in the hydraulic fluid. This same pressure then acts on a much larger piston (the ram).

Because the ram has a much larger surface area, the resulting force is magnified enormously. This allows a relatively small electric pump to generate many tons of compressive force.

Deconstructing the Machine: Key Systems

A hydraulic hot press is an integration of three primary systems working in concert.

The Hydraulic System

This is the heart of the machine's power. It consists of a pump that pushes hydraulic fluid (typically oil) from a reservoir into a cylinder. The pressure of this fluid drives the piston, or ram, which in turn moves the platen to press the material. An accumulator may also be used to store high-pressure fluid for rapid force application.

The Heating System (The "Hot" in Hot Press)

The platens—the large, flat steel plates that do the pressing—are equipped with a heating system. This can be achieved through electric heating cartridges inserted into the platens or by circulating hot thermal oil through internal channels. A sophisticated controller monitors and maintains a precise, uniform temperature across the entire platen surface, which is critical for consistent results.

The Structural Frame

The immense force generated by the hydraulic system must be contained. A heavy, rigid mainframe holds the entire assembly together, ensuring that all the pressure is directed into the workpiece and that the machine itself does not deform under the massive load.

Understanding the Trade-offs

While powerful, hydraulic hot presses have specific operational characteristics and limitations that are important to understand.

Power vs. Speed

Hydraulic presses deliver immense, controllable force throughout the entire stroke. However, they are generally slower than mechanical presses, which complete a cycle more rapidly but only deliver maximum force at the very bottom of their stroke.

Heat Uniformity is a Challenge

Achieving and maintaining a perfectly even temperature across very large platens is a significant engineering challenge. Any cold spots can lead to defects in the final product, such as incomplete curing or weak bonds.

Maintenance Requirements

These machines involve multiple complex systems. The hydraulic system requires clean fluid, intact seals, and a healthy pump. The heating system has electrical components or thermal fluid circuits that also need regular inspection and maintenance to ensure safety and performance.

Making the Right Choice for Your Application

Choosing to use a hydraulic hot press depends entirely on whether your process requires the simultaneous application of both heat and pressure.

- If your primary focus is bonding or laminating (e.g., plywood, decorative panels): The press is essential for activating adhesives and ensuring a strong, void-free bond across a large surface.

- If your primary focus is molding composites or plastics: The heat makes the material pliable, while the sustained pressure shapes it and holds it in place as it cures or cools into a solid, final form.

- If your primary focus is simply high-tonnage forming of metal at room temperature: A standard hydraulic press (without the heating system) is the more appropriate and cost-effective tool.

Ultimately, the value of a hydraulic hot press lies in its unique ability to combine and control both thermal and mechanical energy to transform materials.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Applies simultaneous heat and high pressure to materials. |

| Key Principle | Uses Pascal's Law for hydraulic force multiplication. |

| Primary Systems | Hydraulic system, heating system (platens), and structural frame. |

| Common Applications | Bonding (plywood, panels), molding composites, and curing plastics. |

Ready to transform your materials with precision?

A hydraulic hot press is essential for processes requiring controlled heat and pressure. KINTEK specializes in lab equipment and consumables, providing reliable solutions for your laboratory's bonding, molding, and curing needs.

Contact us today to find the perfect press for your application!

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What is the role of a hydraulic press with heating plates in copper welding tests? Analyze Stress & Thermal Cycles

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes