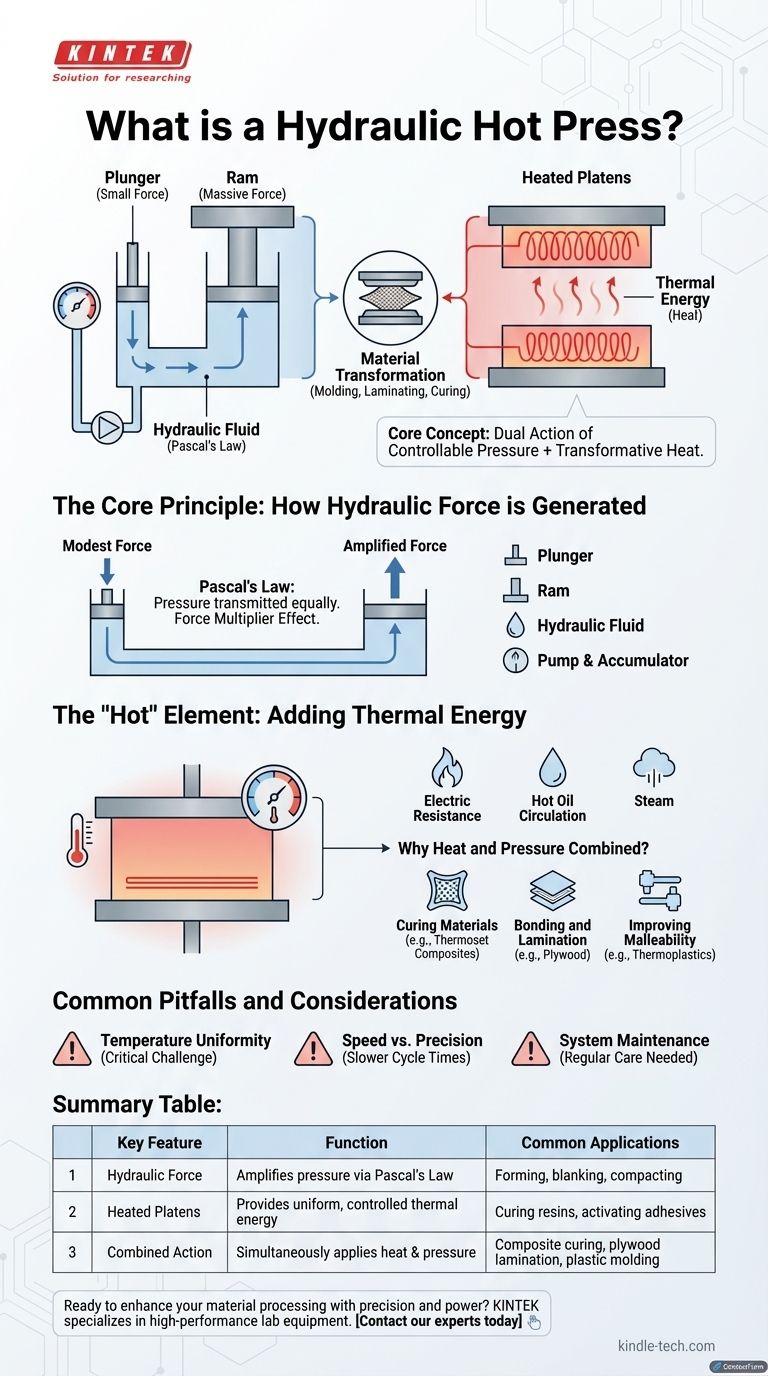

At its core, a hydraulic hot press is a machine that combines two powerful forces: the immense, controllable pressure generated by a hydraulic system and the transformative energy of heat. It uses heated plates, called platens, to apply both pressure and elevated temperatures to a material simultaneously. This dual action is essential for processes like molding, laminating, and curing advanced materials that require both forces to achieve their final form and properties.

The critical insight is that a hydraulic hot press isn't just about crushing something; it's about fundamentally changing a material's state. It uses Pascal's Law to create massive compressive force, while integrated heating elements provide the thermal energy needed to cure resins, bond layers, or make materials pliable for forming.

The Core Principle: How Hydraulic Force is Generated

A hydraulic press operates on a simple but powerful principle of fluid mechanics that allows it to multiply force significantly.

Pascal's Law in Action

The entire system is based on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

Imagine two connected cylinders filled with oil, one small and one large. Pushing down on the small cylinder (the plunger) with a small force creates pressure in the oil. This same pressure pushes up on the large cylinder (the ram), but because the ram has a much larger surface area, the resulting upward force is dramatically amplified.

Key Components of the System

A standard hydraulic system consists of a few primary parts:

- Plunger: The small piston where the initial, smaller force is applied.

- Ram: The large piston that delivers the amplified, massive compressive force.

- Hydraulic Fluid: An incompressible liquid, typically oil, that transfers the pressure from the plunger to the ram.

- Pump & Accumulator: A pump creates the initial fluid pressure. An accumulator can be used to store this high-pressure liquid, releasing it when a strong, rapid thrust is needed.

The Force Multiplication Effect

The "magic" of the hydraulic press is the mechanical advantage it creates. A modest force applied to the small plunger generates a massive force at the large ram, enabling the machine to bend, form, and compress incredibly strong materials with high precision.

The "Hot" Element: Adding Thermal Energy

The defining feature of a hot press is the integration of a controlled heating system, which works in concert with the hydraulic pressure.

The Role of Heated Platens

The surfaces that make contact with the workpiece are called platens. In a hot press, these are thick metal plates engineered with internal heating systems.

Heating can be achieved through electric resistance cartridges, channels for circulating hot oil, or even steam. Sophisticated controls ensure the platens reach and maintain a precise, uniform temperature across their entire surface.

Why Heat and Pressure are Combined

Combining heat and pressure unlocks manufacturing capabilities that neither force could achieve alone.

- Curing Materials: Heat acts as a catalyst for chemical reactions in materials like thermoset composites (e.g., carbon fiber). It cures the resin, while pressure compacts the layers and squeezes out any voids.

- Bonding and Lamination: In woodworking, heat activates the adhesives used to bond layers of wood veneer into plywood or to apply a laminate finish to a substrate. The pressure ensures a complete, uniform bond.

- Improving Malleability: For thermoplastics or rubber, heat softens the material, making it pliable. The hydraulic pressure then easily forces the softened material to conform to the shape of a mold.

Common Pitfalls and Considerations

While powerful, hydraulic hot presses require careful operation and present unique challenges.

Temperature Uniformity is Critical

Achieving and maintaining a perfectly even temperature across large platens is a significant engineering challenge. Any cold or hot spots can lead to improperly cured sections, weak bonds, or warped parts, ultimately resulting in product failure.

Speed vs. Precision

Hydraulic presses offer unparalleled control over force, but they are typically slower than their mechanical counterparts. The time required for the platens to heat up and cool down (cycle time) is a major factor in production efficiency.

System Maintenance

The combination of high pressure and high temperature puts significant stress on the machine's components. Regular maintenance of hydraulic seals, fluid levels, and heating elements is essential to ensure safety and consistent performance.

Making the Right Choice for Your Goal

Selecting the right press depends entirely on the material you are working with and your desired outcome.

- If your primary focus is curing thermoset composites like carbon fiber or fiberglass: A hydraulic hot press is non-negotiable, as both heat and pressure are required to properly cure the resin matrix.

- If your primary focus is producing plywood or laminated panels: The hot press is the industry standard for activating adhesives and ensuring strong, uniform bonds between layers.

- If your primary focus is high-force metal forming like blanking or forging: A standard (cold) hydraulic or mechanical press is sufficient, as heat is not required for the forming process itself.

- If your primary focus is molding thermoplastics or rubber: A hot press is ideal for softening the material and applying the pressure needed to fill a mold accurately.

Ultimately, understanding the distinct roles of hydraulic force and thermal energy is the key to leveraging this technology for advanced material processing.

Summary Table:

| Key Feature | Function | Common Applications |

|---|---|---|

| Hydraulic Force | Amplifies pressure via Pascal's Law to compress materials | Forming, blanking, compacting |

| Heated Platens | Provides uniform, controlled thermal energy | Curing resins, activating adhesives, softening materials |

| Combined Action | Simultaneously applies heat and pressure for material transformation | Composite curing, plywood lamination, plastic molding |

Ready to enhance your material processing with precision and power? KINTEK specializes in high-performance lab equipment, including hydraulic hot presses designed for curing composites, laminating panels, and molding advanced materials. Our solutions deliver the exact heat and pressure control your laboratory needs for reliable, repeatable results. Contact our experts today to find the perfect press for your application!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density