At its core, a hydraulic hot press is a machine that combines two powerful principles: immense compressive force generated by a hydraulic system and intense heat delivered through integrated plates. It uses hydraulic fluid to multiply a small initial force into a massive, evenly distributed pressure on a workpiece, while simultaneously heating that workpiece to facilitate shaping, bonding, or curing.

A hydraulic hot press is not just about crushing something. It is a precision tool designed to use heat to make a material pliable or to activate an adhesive, and then use immense, uniform pressure to permanently shape or bond it.

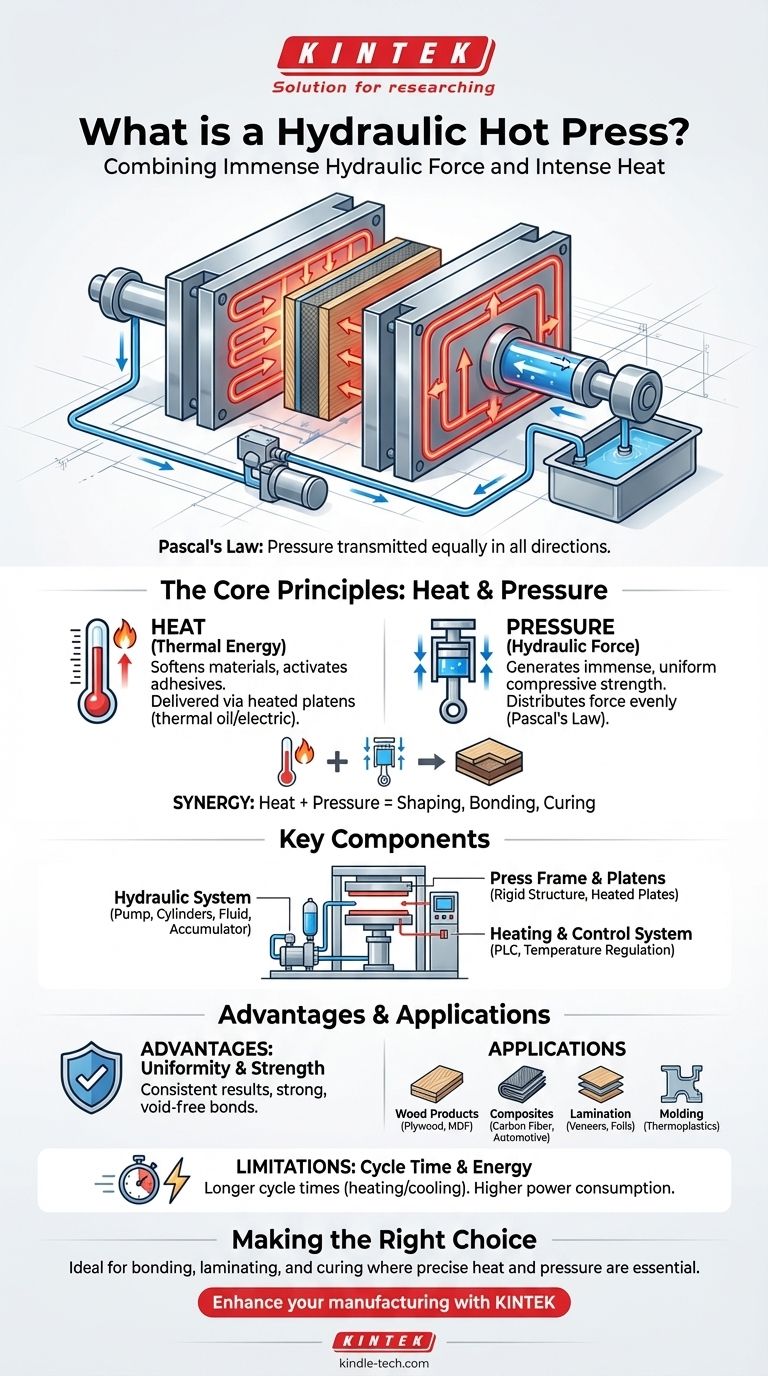

The Two Core Principles: Heat and Pressure

To understand a hydraulic hot press, you must first understand its two distinct but cooperative functions. The machine's power comes from the interplay between its hydraulic force and its thermal energy.

How Hydraulic Pressure Works (Pascal's Law)

The force of the press is governed by a fundamental principle of fluid mechanics known as Pascal's Law. This law states that pressure exerted on a confined fluid is transmitted evenly in all directions.

A simple hydraulic press consists of two interconnected cylinders of different sizes, filled with a fluid like oil. The smaller cylinder is the plunger, and the larger one is the ram.

When a small force is applied to the plunger, it creates pressure in the fluid. Because this pressure is distributed equally throughout the fluid, it acts on the much larger surface area of the ram, generating a proportionally larger force. This mechanical advantage allows the press to produce immense compressive strength.

The Role of the Heated Platens

The "hot" in a hydraulic hot press comes from its platens—the large, flat steel plates that make direct contact with the material being pressed.

These platens contain internal heating elements or channels through which heated fluid (like thermal oil) circulates. This system transfers thermal energy directly and uniformly into the workpiece.

Why Combine Heat and Pressure?

The synergy between heat and pressure is what makes this machine so effective for specific manufacturing processes.

Heat serves to soften materials like wood fibers, plastics, or resins, making them malleable. For other applications, like lamination, the heat is necessary to activate thermosetting adhesives.

Once the material is heated to the optimal temperature, the hydraulic system engages, applying uniform pressure to consolidate layers, shape the material into a mold, or ensure a complete and permanent bond.

Key Components of a Hydraulic Hot Press

While designs vary, nearly all hydraulic hot presses share a common set of core components that work in concert.

The Hydraulic System

This is the heart of the machine's force. It includes a hydraulic pump to create pressure, the cylinders (ram and plunger), and the hydraulic fluid that transmits the force. Some advanced presses also use a hydraulic accumulator to store high-pressure liquid, allowing for rapid releases of force when needed.

The Press Frame and Platens

The machine is built around a heavy, rigid frame designed to withstand the tremendous forces it generates without deforming. The platens are mounted within this frame and must be perfectly flat and parallel to ensure even pressure and heat distribution across the entire workpiece.

The Heating and Control System

This system, often managed by a PLC (Programmable Logic Controller), precisely regulates the temperature of the platens. Maintaining a consistent temperature is critical for achieving repeatable, high-quality results, whether curing a composite or bonding a laminate.

Understanding the Trade-offs and Applications

Like any specialized tool, a hydraulic hot press has distinct advantages and is suited for specific tasks. Understanding these is key to knowing when to use one.

The Primary Advantage: Uniformity and Strength

The single greatest advantage of a hydraulic hot press is its ability to deliver consistent results. Pascal's Law ensures the pressure is perfectly even, and modern heating systems provide uniform temperature. This combination is ideal for creating strong, void-free bonds in laminates and perfectly cured composite parts.

Common Applications

The unique capabilities of the hot press make it essential in industries that require bonding, curing, or forming under heat. Key applications include:

- Wood Products: Manufacturing plywood, particleboard (MDF), and laminated veneer lumber (LVL).

- Composites: Curing carbon fiber parts and forming sheet molded composites (SMC) or glass mat transfer (GMT) materials for the automotive and aerospace industries.

- Lamination: Applying veneers, foils, or plastic laminates to substrates.

- Molding: Forming thermoplastic sheets and other heat-sensitive materials.

Key Limitations: Cycle Time and Energy

The primary trade-off is speed. Heating the massive platens and the workpiece to the target temperature takes time, as does the subsequent cooling period. This results in longer cycle times compared to a "cold" press operation. Furthermore, the energy required to maintain high temperatures makes it a more power-intensive process.

Making the Right Choice for Your Goal

Choosing the right manufacturing process depends entirely on your material and desired outcome.

- If your primary focus is bonding or laminating materials like wood or composites: A hydraulic hot press is ideal because the heat activates adhesives while the pressure ensures a strong, uniform bond.

- If your primary focus is molding thermoplastics or curing composite resins: The hot press provides the necessary thermal energy to make the material pliable or trigger a chemical reaction, while the hydraulic force shapes it precisely.

- If your primary focus is simply compressing or forming a material without thermal activation: A standard (cold) hydraulic press may be a more energy-efficient and faster solution.

Ultimately, a hydraulic hot press excels wherever the controlled application of both immense force and high temperature is required to transform a material.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Applies heat and immense, uniform hydraulic pressure to materials. |

| Key Principle | Uses Pascal's Law to multiply force; heated platens deliver thermal energy. |

| Primary Advantage | Creates strong, void-free bonds and ensures consistent, high-quality results. |

| Common Applications | Plywood/MDF production, composite curing (carbon fiber), lamination, thermoplastic molding. |

| Key Limitation | Longer cycle times due to heating/cooling phases; higher energy consumption. |

Ready to enhance your manufacturing process with precision heat and pressure?

At KINTEK, we specialize in high-performance lab equipment, including hydraulic hot presses designed for reliability and superior results in bonding, laminating, and composite curing. Whether you're working with wood products, advanced composites, or laminates, our expertise ensures you get the right solution for your specific laboratory and production needs.

Contact us today to discuss how a KINTEK hydraulic hot press can bring strength and consistency to your operations.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why must electric heating elements be wrapped around the pellet forming die? Boost Oat Straw Pellet Quality

- What is the core function of a laboratory heated hydraulic press in CSP? Revolutionize Low-Temp Ceramic Sintering

- Why are precision molds and pressure control essential for TlBr hot pressing? Enhance Semiconductor Performance

- What are the solutions for mitigating issues caused by steam condensation and air in hot press platens?

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- How does a laboratory hot press improve alloy performance? Optimize Liquid Phase Sintering for High-Strength Materials

- What is the temperature and pressure of hot pressing? Tailoring Parameters for Your Material

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts