Understanding the types of power presses is less about counting a definitive number and more about understanding the fundamental ways they are classified. There isn't a single answer, as presses are categorized by their power source, their frame design, and their specific function, leading to dozens of combinations. The two most critical classifications are the drive system and the frame type.

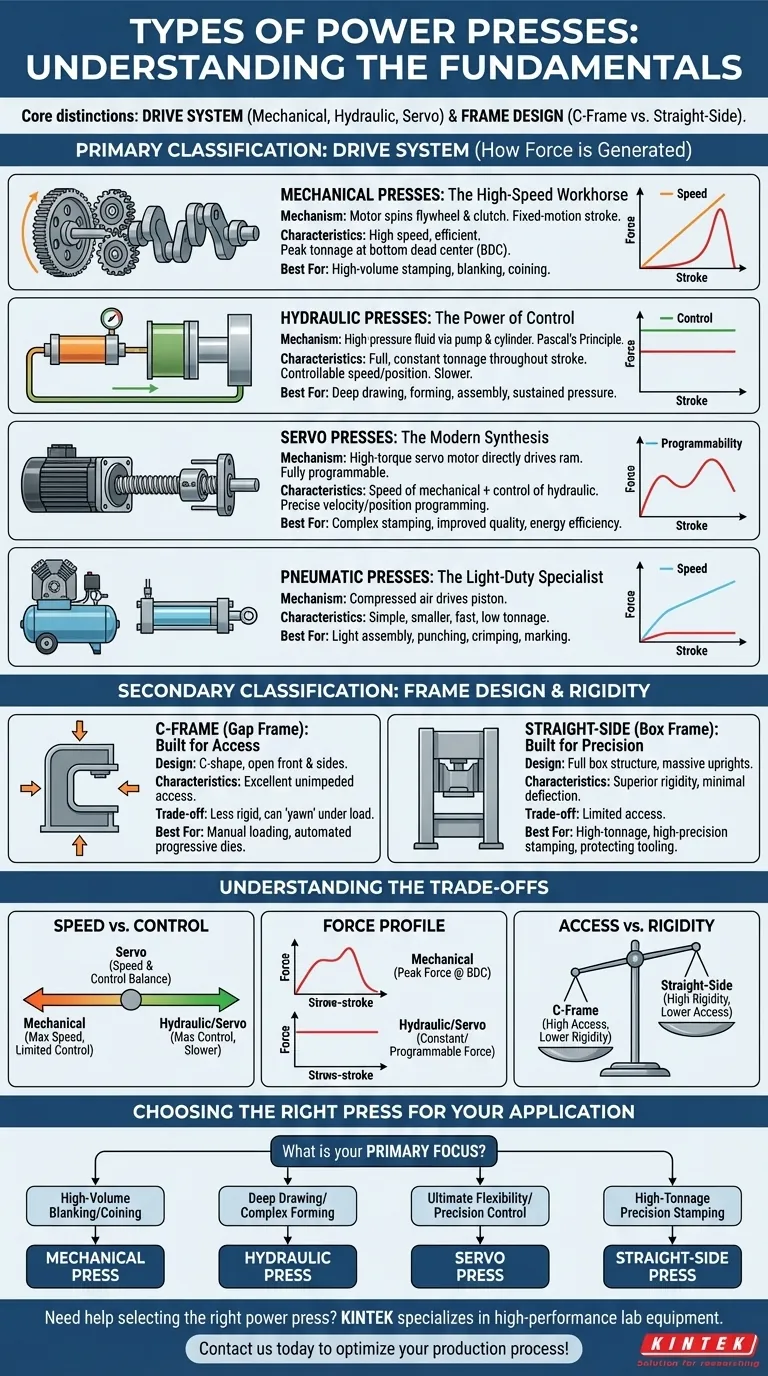

The core distinction between power presses lies in their drive system—Mechanical, Hydraulic, and Servo—which dictates their speed, force profile, and control. This, combined with their frame design—C-Frame versus Straight-Side—determines the specific manufacturing applications for which each is best suited.

The Primary Classification: How a Press Generates Force

The method a press uses to create force is the most significant factor influencing its performance, capabilities, and ideal use case.

Mechanical Presses: The High-Speed Workhorse

A motor spins a heavy flywheel, storing a massive amount of kinetic energy. When the operator engages the clutch, this energy is transferred through a crankshaft or eccentric gear system, driving the ram down in a fixed-motion stroke.

These presses are exceptionally fast and efficient, making them the standard for high-volume stamping, blanking, and coining operations where speed is paramount.

A key characteristic is that a mechanical press only delivers its maximum rated tonnage at the very bottom of its stroke.

Hydraulic Presses: The Power of Control

Hydraulic presses use a large piston and cylinder driven by high-pressure fluid, based on Pascal's principle. An electric motor powers a pump to move the fluid.

The defining feature of a hydraulic press is its ability to deliver full, constant tonnage at any point in the ram's stroke. This, combined with complete control over ram speed and position, makes them ideal for deep drawing, forming, and assembly operations that require sustained pressure. They are generally slower than mechanical presses.

Servo Presses: The Modern Synthesis

Also known as servo-mechanical presses, these machines replace the traditional motor, flywheel, and clutch with a high-torque servo motor. The servo motor directly drives the ram's motion, often through a ballscrew or similar mechanism.

This design combines the speed of a mechanical press with the full programmability and control of a hydraulic press. Operators can precisely program the ram's velocity, position, and dwell time, making it perfect for complex stamping operations, improving part quality, and reducing energy consumption.

Pneumatic Presses: The Light-Duty Specialist

These presses use compressed air to drive a piston and generate force. They are simpler, smaller, and faster for their size but are limited to low-tonnage applications.

Pneumatic presses are commonly used for light assembly, punching, crimping, and marking tasks where high force is not the primary requirement.

The Secondary Classification: Frame Design and Rigidity

The frame is the backbone of the press, and its design dictates rigidity and access, directly impacting precision and operational workflow.

C-Frame (Gap Frame): Built for Access

As the name suggests, the frame is shaped like the letter "C." This provides excellent, unimpeded access to the die area from three sides (front, left, and right).

This open design is ideal for jobs requiring manual loading and unloading of parts or for feeding material from the side in automated progressive die operations.

Straight-Side (Box Frame): Built for Precision

Straight-side presses feature a full box-style frame with two massive uprights. This construction is inherently more robust and rigid than a C-frame design.

This superior rigidity minimizes deflection under heavy loads, making straight-side presses the mandatory choice for high-tonnage, high-precision stamping and forming that demand consistency and protect expensive tooling.

Understanding the Trade-offs

Selecting a press involves balancing competing factors. No single press is best for every job.

Speed vs. Control

Mechanical presses offer the highest cycle rates but have a fixed stroke and limited control. Hydraulic and servo presses offer complete control over the entire stroke but often at a slower maximum speed or higher initial cost.

Force Profile

This is a critical distinction. Mechanical presses only hit peak tonnage at the bottom dead center of the stroke. If your job requires force higher up in the stroke (like deep drawing), a hydraulic or servo press is necessary as they provide full tonnage throughout.

Access vs. Rigidity

C-frame presses offer unmatched accessibility, simplifying die changes and part handling. However, under load, the "gap" can open slightly ("yawning"), affecting precision. Straight-side presses sacrifice this access for the extreme rigidity needed for heavy, precise work.

Choosing the Right Press for Your Application

Your final decision must be driven by the specific demands of your manufacturing task.

- If your primary focus is high-volume blanking or coining: A mechanical press is almost always the most cost-effective and efficient solution.

- If your primary focus is deep drawing or complex forming: A hydraulic press offers the consistent tonnage and control needed for these operations.

- If your primary focus is ultimate flexibility and precision control: A servo press provides unparalleled programmability for complex jobs, combining speed and control.

- If your primary focus is accessibility for automation or manual loading: A C-Frame design is ideal, but be mindful of its tonnage and precision limitations.

- If your primary focus is high-tonnage precision stamping: A straight-side press provides the essential rigidity to ensure part quality and extend die life.

By understanding these core principles of force generation and frame construction, you can confidently select the press that functions as a precise tool for your specific manufacturing goal.

Summary Table:

| Classification | Key Types | Primary Characteristics | Best For |

|---|---|---|---|

| Drive System | Mechanical, Hydraulic, Servo, Pneumatic | Speed, force control, programmability | High-volume stamping, deep drawing, precision forming |

| Frame Design | C-Frame, Straight-Side | Accessibility vs. rigidity | Manual loading, automated progressive dies, high-tonnage precision |

Need help selecting the right power press for your lab or manufacturing operation? KINTEK specializes in providing high-performance lab equipment and consumables tailored to your specific needs. Whether you require the speed of a mechanical press, the control of a hydraulic system, or the precision of a servo press, our experts can guide you to the ideal solution. Contact us today to optimize your production process and achieve superior results!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production