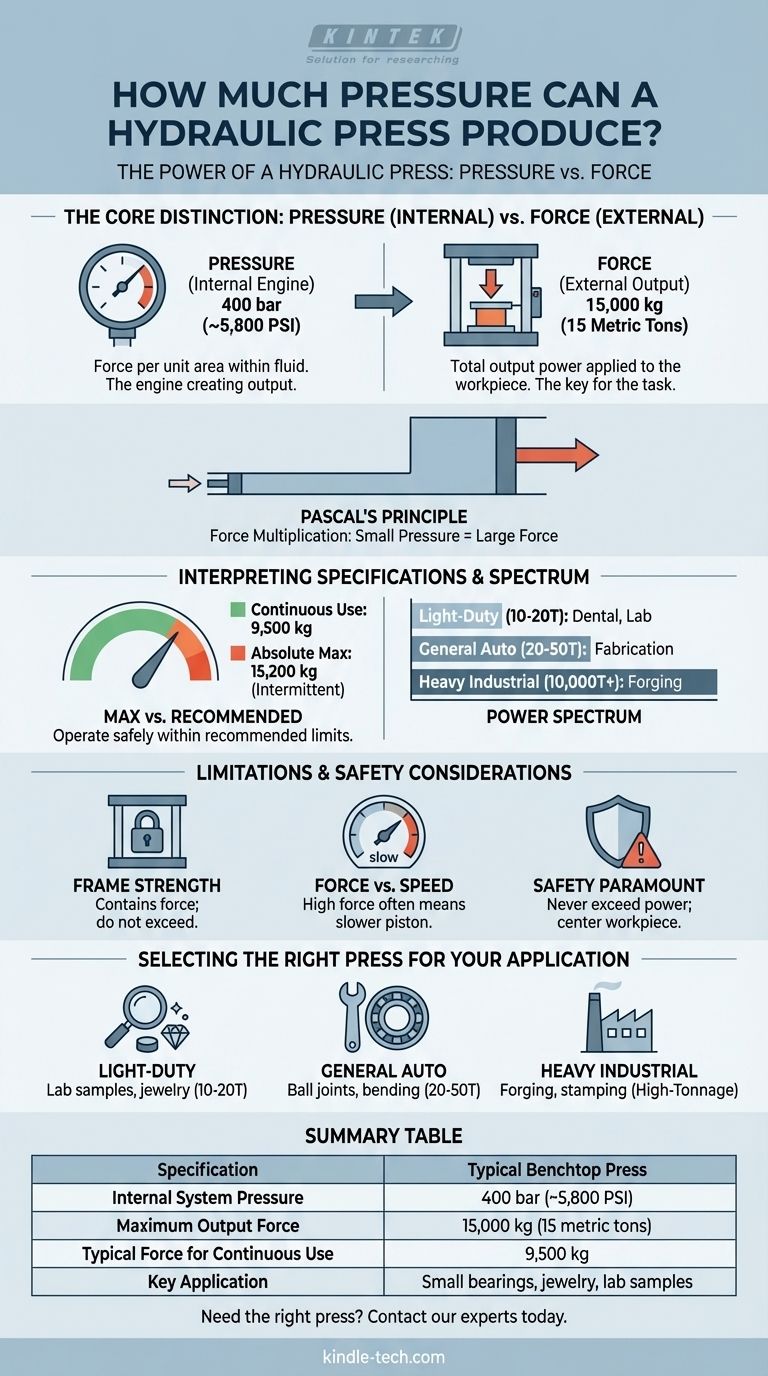

The power of a hydraulic press is defined by two related but distinct metrics: pressure and force. Based on typical benchtop models, a hydraulic press can operate at a pressure of 400 bar (approximately 5,800 PSI). This internal hydraulic pressure allows the machine to generate an immense external pressing force of up to 15,000 kg (around 15 metric tons or 16.5 US tons).

The most critical concept to understand is that the hydraulic system's internal pressure (measured in bar or PSI) is the engine that creates the machine's usable output force (measured in tons or kg). Focusing on the output force is key to choosing the right press for a specific task.

The Fundamental Principle: Pressure vs. Force

To truly understand a hydraulic press's capability, you must distinguish between the pressure inside the system and the force it exerts on an object. This relationship is the foundation of all hydraulic power.

Understanding Pascal's Principle

A hydraulic press operates on Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted equally throughout the fluid. A small force applied to a small piston generates pressure, which is then transferred to a much larger piston, multiplying the initial force.

This force multiplication is what allows a person using a simple hand lever to generate enough power to bend steel.

What is Pressure? (Bar, PSI, kg/cm²)

Pressure is the amount of force exerted per unit of area within the hydraulic fluid itself. It is the internal system rating.

The example presses operate at a pressure capacity of 400 bar. Since one bar is nearly equivalent to one kg/cm², this is often written as 400 kg/cm². For reference, 400 bar is approximately 5,800 PSI (Pounds per Square Inch).

What is Force? (Tons, Kilograms)

Force is the total output power of the press—the actual "crushing" or "pressing" capacity applied to the workpiece. This is the specification that matters most for getting a job done.

A press with an internal pressure of 400 bar can generate a resulting force of 15,000 kg, which is equivalent to 15 metric tons.

Interpreting Hydraulic Press Specifications

When evaluating a press, several numbers define its performance and safety limits. Understanding them is crucial for proper operation.

Maximum vs. Recommended Ratings

You will often see two force ratings: a maximum allowed power and a maximum recommended power.

For example, a press might have a maximum recommended force of 9,500 kg for continuous, everyday work. It may also have an absolute maximum allowed force of 15,200 kg, which should only be used intermittently to avoid excessive wear or damage to the system.

The Spectrum of Power

The capabilities of hydraulic presses vary enormously depending on their application.

Small, specialized units like a dental press might provide 15 tons of force. A common automotive workshop press is typically in the 20 to 50-ton range. Massive industrial forging presses, however, can generate forces exceeding 10,000 tons.

Understanding the Trade-offs and Limitations

While incredibly powerful, hydraulic presses are governed by physical limitations and require careful handling.

The Role of the Frame

The hydraulic system generates the force, but the steel frame of the press must contain it. A press's true limit is determined by the strength of its frame. Exceeding this limit can cause catastrophic and dangerous failure.

Force vs. Speed

There is an inherent trade-off between force and the speed of the piston. Systems designed to produce extremely high forces, like the example press with its 25 mm piston stroke, often move very slowly. This allows for precise control but is not suited for high-speed production.

Safety is Paramount

Due to the extreme forces involved, you must never operate a press beyond its recommended power rating. Always ensure the workpiece is properly centered and that the press frame is structurally sound and free of cracks or damage.

Making the Right Choice for Your Application

Selecting the right hydraulic press requires matching its rated force to the demands of your specific tasks.

- If your primary focus is light-duty work (e.g., small bearings, jewelry, lab samples): A benchtop press in the 10-20 ton range provides more than enough force with excellent control.

- If your primary focus is general automotive or fabrication (e.g., ball joints, large bearings, bending metal): A floor-standing press in the 20-50 ton range is the industry standard.

- If your primary focus is heavy industrial manufacturing (e.g., forging, stamping, deep drawing): You need a specialized, high-tonnage industrial press sized specifically for the production process.

Ultimately, matching the press's rated force to your specific job ensures safety, efficiency, and the best possible result.

Summary Table:

| Specification | Typical Benchtop Hydraulic Press |

|---|---|

| Internal System Pressure | 400 bar (~5,800 PSI) |

| Maximum Output Force | 15,000 kg (15 metric tons) |

| Typical Force for Continuous Use | 9,500 kg |

| Key Application | Small bearings, jewelry, lab samples |

Need the right press for your specific force requirements?

Whether you're working in a laboratory, an automotive workshop, or a fabrication shop, matching the press's force to your task is critical for safety and results. KINTEK specializes in lab equipment and consumables, offering a range of hydraulic presses designed to meet your precise needs.

Contact our experts today to discuss your application and find the perfect hydraulic press solution for your workshop or lab.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis

- What is the role of a laboratory hydraulic pellet press and stainless steel molds in the fabrication of RuO2/NbC anodes?

- What is the difference between a hydraulic press and a servo press? Choosing the Right Force for Your Application

- When was hydraulic press invented? Joseph Bramah's 1795 Revolution in Force Multiplication

- How does a hydraulic press machine work? Harnessing Pascal's Law for Immense Force

- Why is a uniaxial hydraulic press utilized for cold-pressing metal powders? Enhance Your Sintering Quality

- Why is step-by-step pressing required for ASSNIB assembly? Optimize Solid-Solid Contact and Conductivity

- What is pressed pellets? Transform Powders into Reliable Solid Samples for Analysis