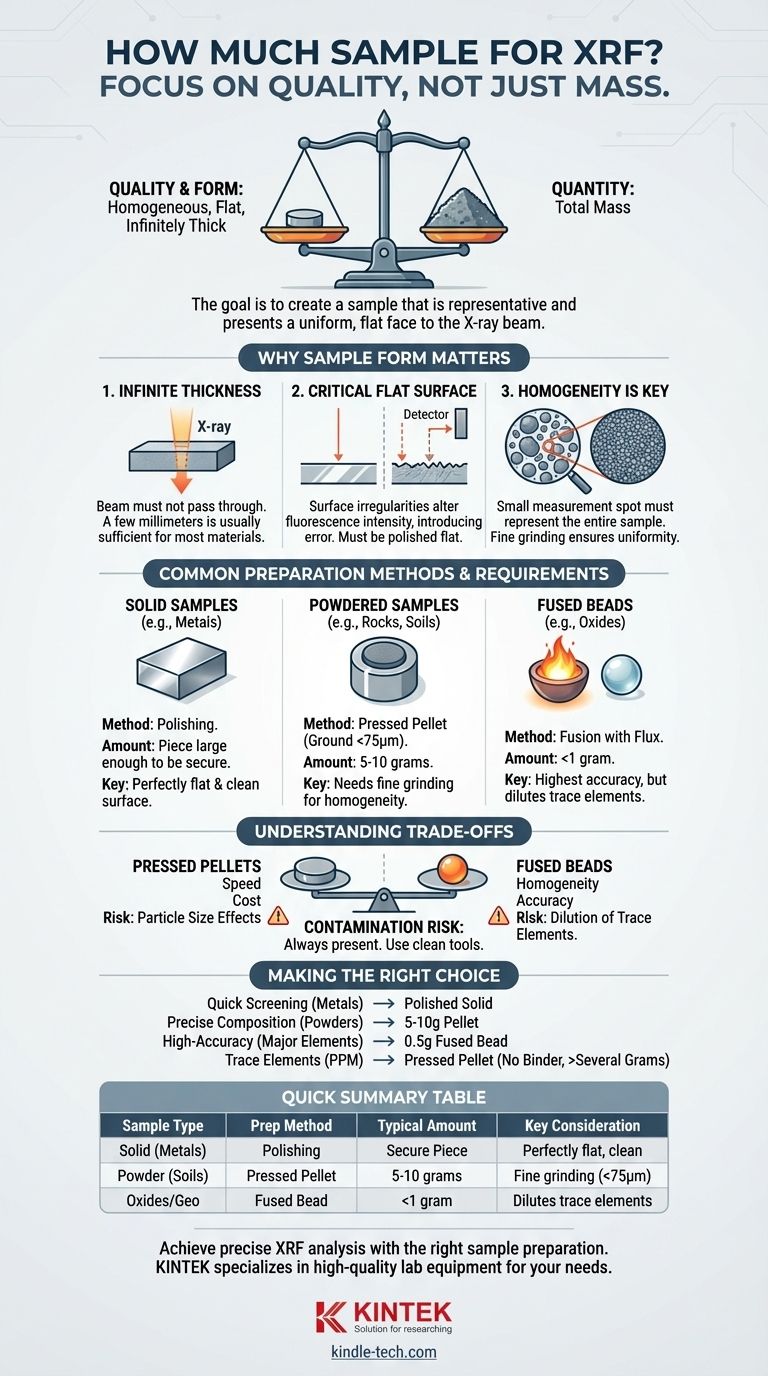

For XRF analysis, the required sample amount is not defined by a specific weight or volume, but by its ability to form a sample that is sufficiently thick, homogeneous, and has a perfectly flat surface for measurement. The focus is on the quality and form of the prepared sample rather than its total mass.

The central challenge in XRF is not gathering a specific quantity of material, but preparing what you have into a form the instrument can measure accurately. Your goal is to create a sample that is representative of the source material and presents a uniform, flat face to the X-ray beam.

Why Sample Form Matters More Than Sample Mass

Many analysts new to X-ray Fluorescence (XRF) focus on how many grams of material to collect. However, the accuracy of your results is determined by the physical characteristics of the sample you place in the instrument, not its starting weight.

The Principle of "Infinite Thickness"

An X-ray beam only penetrates a limited depth into a sample. "Infinite thickness" is achieved when the sample is thick enough that the X-ray beam does not pass through it. If a sample is too thin, the analysis will be inaccurate.

For most materials, a few millimeters of thickness is sufficient to be "infinitely thick." Therefore, you only need enough material to create a pressed pellet or solid object of this depth.

The Critical Role of a Flat Surface

XRF instruments are precisely calibrated based on a fixed distance between the X-ray source, the sample surface, and the detector.

Any surface irregularity—scratches, curves, or roughness—changes this distance. This alters the intensity of the fluorescence measured by the detector, introducing significant error into your final results. This is why solid samples must be polished flat.

The Need for Homogeneity

An XRF analyzer measures a relatively small spot on the sample's surface. For the results to be meaningful, that small spot must be perfectly representative of the entire sample.

If your sample is a mix of different particles (like a mineral powder), it must be ground very finely and mixed thoroughly to ensure homogeneity. Otherwise, the instrument might disproportionately measure one type of particle, skewing the results.

Common Sample Preparation Methods and Their Requirements

The amount of material you need is a direct function of the preparation method required for your sample type.

Solid Samples (e.g., Metals, Alloys)

For a uniform piece of metal, you do not need a large quantity. You only need a piece large enough to be securely placed in the instrument and prepared with a perfectly flat and clean surface. Preparation often involves polishing with a grinder or lathe.

Powdered Samples (e.g., Rocks, Soils, Cement)

This is the most common method. The goal is to create a pressed pellet.

The sample is first ground into a fine powder, typically with a grain size under 75 micrometers. You generally need a few grams of this powder to create a robust pellet in a standard die set (e.g., 32mm or 40mm diameter). If the powder does not bind well under pressure, a small amount of wax binder is added.

Fused Beads (e.g., Oxides, Geological Samples)

For the highest accuracy, powders can be prepared as fused beads. This involves mixing a small, precise amount of sample with a larger amount of a flux (like a lithium borate salt) and melting it in a crucible.

This process requires very little sample—often less than a gram—but the sample is heavily diluted by the flux.

Understanding the Trade-offs

Each preparation method comes with its own set of advantages and disadvantages that influence the quality of your analysis.

Pressed Pellets: Speed vs. Particle Effects

Pressed pellets are fast, cheap, and excellent for many applications. However, if the powder is not ground finely enough, "particle size effects" can occur, where larger, less dense particles can lead to inaccurate measurements, especially for lighter elements.

Fused Beads: Homogeneity vs. Dilution

Fusing a sample with flux eliminates all particle size effects, creating a perfectly homogeneous glass bead. This is the gold standard for accuracy. The trade-off is dilution. Your sample is diluted in the flux, which can make it impossible to detect elements present at very low, trace-level concentrations.

Contamination Risk is Always a Factor

Regardless of the method, you must prevent cross-contamination. Using dirty grinders or the same file for different alloys can introduce foreign elements into your sample. A contaminated sample will produce an inaccurate result, no matter how much material you started with.

Making the Right Choice for Your Goal

Select your sample size and preparation method based on your analytical objective.

- If your primary focus is quick screening of a metal alloy: You only need a piece large enough to present a clean, flat surface to a portable or benchtop XRF analyzer.

- If your primary focus is precise compositional analysis of a powder (e.g., soil, ore): Plan to collect at least 5-10 grams to ensure you have enough material to grind and press a high-quality, homogeneous pellet.

- If your primary focus is high-accuracy analysis of major and minor elements: The fused bead method is superior, for which you may only need half a gram of representative sample material.

- If your primary focus is detecting trace elements (parts-per-million): Avoid the fused bead method due to dilution. Use a pressed pellet, ensuring you have enough representative material (several grams) to create a pellet without binder, if possible.

Ultimately, a successful XRF analysis depends not on the quantity of your sample, but on the quality of its preparation.

Summary Table:

| Sample Type | Preparation Method | Typical Amount Needed | Key Consideration |

|---|---|---|---|

| Solid (Metals, Alloys) | Polishing | Piece large enough to secure | Must have a perfectly flat, clean surface |

| Powder (Soils, Ores, Cement) | Pressed Pellet | 5-10 grams | Requires fine grinding (<75 µm) for homogeneity |

| Oxides, Geological | Fused Bead | <1 gram | Highest accuracy but dilutes trace elements |

Achieve precise and reliable XRF analysis with the right sample preparation. The quality of your results depends on proper technique and equipment. KINTEK specializes in high-quality lab equipment and consumables for all your XRF sample prep needs—from grinding mills and pellet presses to fusion fluxers. Let our experts help you optimize your workflow for accurate elemental analysis. Contact us today to discuss your specific application and ensure your samples are prepared for success!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation

- What is the use of hydraulic press in laboratory? Achieve Precise Sample Prep & Materials Testing

- What are the disadvantages associated with the KBr technique? Avoid Common Errors in IR Spectroscopy

- Why do we use KBr in IR spectroscopy? Achieve Clear, High-Quality Solid Sample Analysis

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep