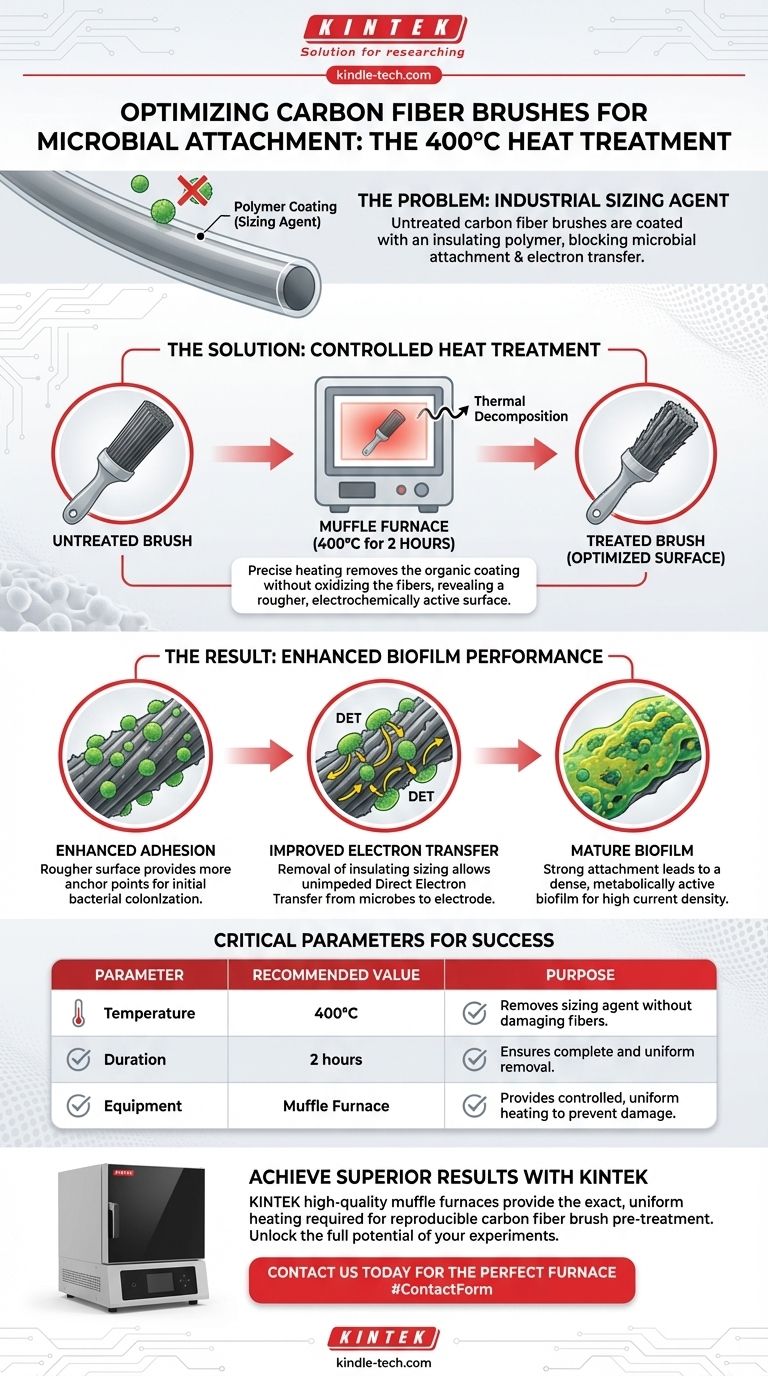

To properly pre-treat a carbon fiber brush, you must heat it in a muffle furnace at 400°C for 2 hours. This thermal treatment is designed to remove the industrial sizing agent from the fibers. The result is a rougher, more electrochemically active surface that is significantly better at attracting and sustaining a robust microbial biofilm.

The core problem is that manufactured carbon fibers are coated with a protective polymer that blocks microbial attachment. Heat treatment is not about "cleaning" the brush, but about fundamentally altering its surface chemistry to make it a hospitable and functional electrode for microorganisms.

The "Why" Behind Heat Treatment

Untreated carbon fiber brushes are poorly suited for microbial applications directly out of the box. The reason lies in a non-conductive coating applied during manufacturing.

What is a Sizing Agent?

A sizing agent is a thin polymer coating, similar to a starch or epoxy, applied to carbon fibers during their production.

This agent serves to protect the brittle fibers from damage during handling and weaving. However, for bioelectrochemical applications, this protective layer is a barrier that prevents microbes from making direct physical and electrical contact with the carbon.

The Role of High Temperature

Heating the brush to 400°C provides enough thermal energy to decompose and burn off this polymer sizing agent.

This temperature is carefully chosen because it is high enough to remove the organic coating but low enough to avoid oxidizing or damaging the underlying carbon fiber structure, which would compromise its integrity and conductivity.

The Result: An Optimized Surface

After treatment, the carbon fiber surface is transformed in two critical ways.

First, it becomes significantly rougher, increasing the microscopic surface area and providing more anchor points for initial bacterial adhesion. Second, it exposes electrochemically active sites on the carbon, which are essential for electron transfer.

Impact on Biofilm Formation and Performance

This simple pre-treatment step has a direct and profound impact on the performance of any bioelectrochemical system, such as a microbial fuel cell (MFC).

Enhanced Microbial Adhesion

The newly roughened and chemically active surface acts as a superior substrate for the initial attachment of microbes. This is the critical first step in forming a healthy biofilm. A surface without this treatment is too smooth and inert for effective colonization.

Improved Electron Transfer

The primary function of a carbon fiber brush anode is to accept electrons from microbes. The sizing agent is an electrical insulator. By removing it, you create a direct, unimpeded pathway for Direct Electron Transfer (DET) from the bacterial membrane to the electrode.

A Foundation for a Mature Biofilm

A strong initial attachment leads to the development of a thick, dense, and metabolically active biofilm. This mature biofilm is what drives high performance, resulting in greater current density and more efficient waste conversion or power production.

Understanding the Critical Parameters

The success of the treatment depends on adhering to the specific protocol. Deviating from the established temperature or time can lead to suboptimal results or even damage your materials.

Why 400°C is the Sweet Spot

If the temperature is too low, the sizing agent will not be completely removed, leaving an insulating barrier on the fibers. If the temperature is too high, you risk oxidizing the carbon fibers, which can decrease their conductivity and make them brittle.

The Importance of Duration

A duration of 2 hours ensures that heat penetrates the entire dense structure of the brush and that the sizing agent is completely decomposed. Shorter treatment times may result in an uneven or incomplete removal, leading to inconsistent performance across the electrode.

The Need for a Muffle Furnace

A muffle furnace is critical because it provides a highly controlled and uniform heating environment. Using a less precise method like a torch or a standard oven can cause hot spots, leading to uneven treatment and potential damage to the fibers.

Making the Right Choice for Your Goal

Proper pre-treatment is not an optional step; it is foundational to the success of your project.

- If your primary focus is maximizing initial colonization: This heat treatment is the most effective way to create a surface that is physically and chemically receptive to bacteria.

- If your primary focus is achieving high current density: Removing the insulating sizing agent is non-negotiable for enabling the efficient electron transfer that produces high electrical currents.

- If your primary focus is experimental reproducibility: Strictly adhering to the 400°C for 2 hours protocol in a calibrated muffle furnace ensures that every anode you prepare is identical, which is essential for reliable data.

By understanding and correctly applying this procedure, you are setting the stage for a high-performing and successful bioelectrochemical system.

Summary Table:

| Pre-Treatment Parameter | Recommended Value | Purpose |

|---|---|---|

| Temperature | 400°C | Removes sizing agent without damaging carbon fibers. |

| Duration | 2 hours | Ensures complete and uniform removal of the coating. |

| Equipment | Muffle Furnace | Provides controlled, uniform heating to prevent damage. |

| Result | Rougher, electrochemically active surface | Enhances microbial adhesion and electron transfer for a robust biofilm. |

Ready to achieve superior performance in your bioelectrochemical research?

KINTEK specializes in the precise lab equipment essential for your success. Our high-quality muffle furnaces provide the exact, uniform heating required for reliable carbon fiber brush pre-treatment, ensuring consistent and reproducible results in your microbial fuel cell or biofilm studies.

Contact us today using the form below to find the perfect furnace for your laboratory needs and unlock the full potential of your experiments.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- How should carbon cloth used for high-temperature electrolysis be handled after operation? Prevent Irreversible Oxidative Damage

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems