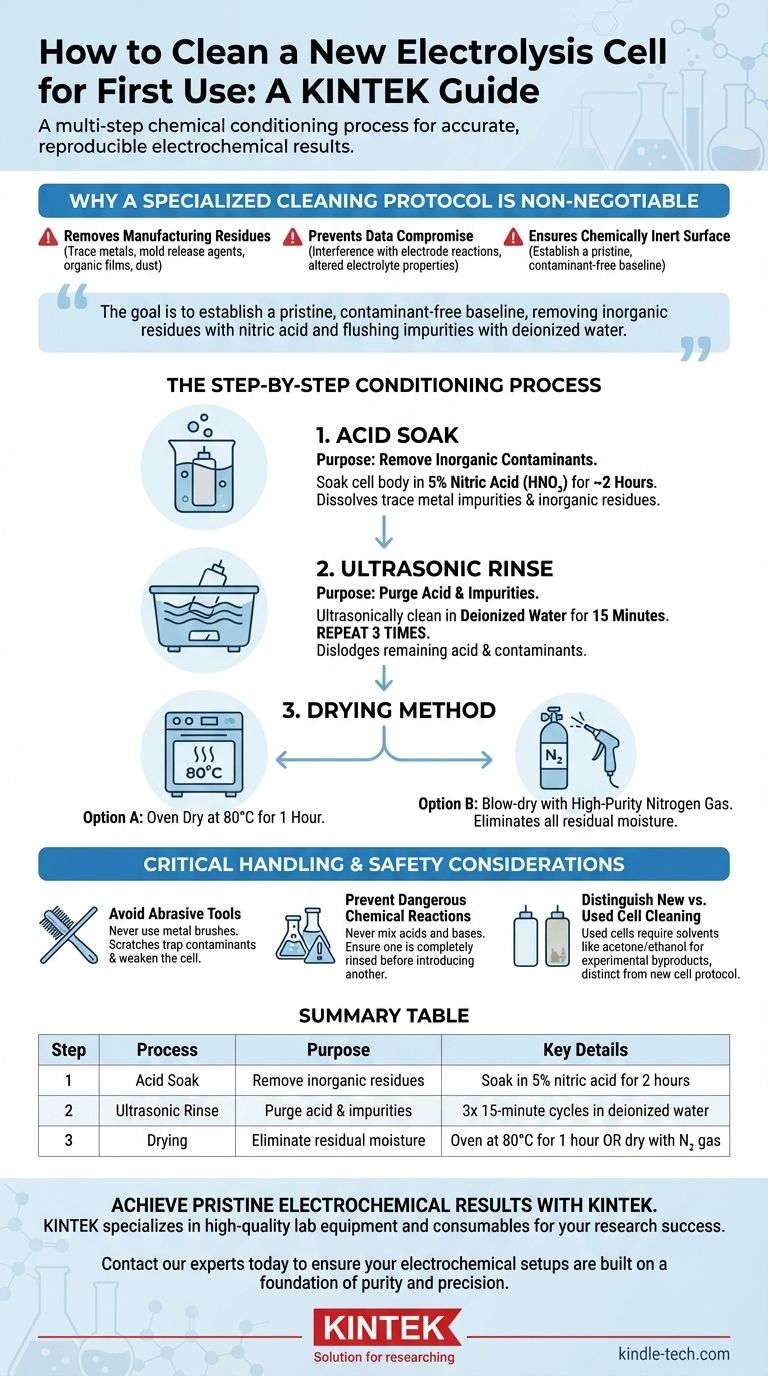

To properly prepare a new electrolysis cell for its first use, you must perform a multi-step chemical cleaning and drying process. The standard procedure involves soaking the cell body in 5% nitric acid for two hours, followed by three rounds of ultrasonic cleaning in deionized water, and finally drying it in an oven or with nitrogen gas. This conditioning is not merely about cleanliness; it is a critical step to remove manufacturing residues and ensure a chemically inert surface for accurate, reproducible results.

The goal of cleaning a new electrolysis cell is to establish a pristine, contaminant-free baseline. This is achieved by using nitric acid to dissolve inorganic manufacturing residues, followed by a thorough deionized water rinse to purge the acid and any remaining impurities.

Why a Specialized Cleaning Protocol is Non-Negotiable

A new electrolysis cell, while appearing clean, can harbor residues from the manufacturing process. These contaminants can include trace metals, mold release agents, organic films, and dust.

Failing to remove these substances will compromise your electrochemical measurements from the very first experiment. They can interfere with electrode reactions, alter your electrolyte's properties, and introduce significant, unpredictable errors into your data.

The Step-by-Step Conditioning Process for a New Cell

This protocol is designed to systematically remove both inorganic and organic contaminants without damaging the glass cell body.

Step 1: The Acid Soak (Removing Inorganic Contaminants)

The first step is to soak the cell body in a 5% nitric acid (HNO₃) solution for approximately two hours.

Nitric acid is a powerful oxidizing agent highly effective at dissolving trace metal impurities and other inorganic residues left on the glass surface from manufacturing and handling. This ensures the cell wall itself is electrochemically inert.

Step 2: The Ultrasonic Rinse (Purging the Acid)

After the acid soak, you must thoroughly rinse the cell. Ultrasonically clean the cell with deionized water for 15 minutes, repeating this process a total of three times.

Ultrasonication provides mechanical agitation that dislodges any remaining acid or dissolved contaminants from the glass surface. Using deionized (or ultrapure) water is critical to prevent re-contaminating the cell with ions commonly found in tap water.

Step 3: The Drying Method (Eliminating Residual Moisture)

The final step is to ensure the cell is completely dry. You have two primary options.

You can dry the cell in an oven at 80℃ for one hour or, for a faster method, blow-dry it completely with high-purity nitrogen gas. This removes all water molecules, which is especially critical for experiments involving non-aqueous electrolytes.

Critical Handling and Safety Considerations

Proper cleaning technique is as much about safety and preserving the equipment as it is about achieving purity.

Avoid Abrasive Tools

Never use metal brushes or other hard abrasives to scrub the cell. These tools will inevitably scratch the glass surface. Scratches not only create sites where contaminants can become trapped but can also weaken the structural integrity of the cell.

Prevent Dangerous Chemical Reactions

A critical safety rule is to never mix acids and bases during a cleaning procedure. For example, adding sodium hydroxide (NaOH) to a cell that still contains nitric acid residue can cause a violent, exothermic reaction. Always ensure one chemical is completely rinsed away before introducing another.

Distinguish New vs. Used Cell Cleaning

The protocol for a new cell is distinct from that for a used one. After an experiment, residues are typically removed with solvents like acetone and ethanol, followed by an ultrapure water rinse. This is because you are targeting specific experimental byproducts, not general manufacturing contaminants.

How to Apply This to Your Research

The rigor of your cleaning protocol should match the sensitivity of your experiment.

- If your primary focus is trace analysis or highly sensitive measurements: Meticulously follow every step of this protocol without compromise, using the highest purity reagents available.

- If your primary focus is general electrochemistry or educational demonstrations: While still critical, the nitrogen drying step can be replaced by thorough oven drying, and a diligent deionized water rinse can suffice if an ultrasonic bath is unavailable.

Properly conditioning your new electrolysis cell is the foundational step that enables trustworthy and reproducible electrochemical data.

Summary Table:

| Step | Process | Purpose | Key Details |

|---|---|---|---|

| 1 | Acid Soak | Remove inorganic residues | Soak in 5% nitric acid for 2 hours |

| 2 | Ultrasonic Rinse | Purge acid & impurities | 3x 15-minute cycles in deionized water |

| 3 | Drying | Eliminate residual moisture | Oven at 80°C for 1 hour or dry with N₂ gas |

Achieve Pristine Electrochemical Results with KINTEK

Starting an experiment with a contaminated cell can compromise your data from the very first run. The specialized cleaning protocol outlined here is essential for removing manufacturing residues and ensuring a chemically inert surface for accurate, reproducible electrochemistry.

At KINTEK, we specialize in providing the high-quality lab equipment and consumables that your research depends on. From durable electrolysis cells to high-purity reagents, we supply the tools you need for success.

Let us support your laboratory's mission for excellence. Contact our experts today to discuss your specific needs and ensure your electrochemical setups are built on a foundation of purity and precision.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments