To properly cool a muffle furnace, you must terminate the power and allow it to cool down naturally with the door completely closed. The core principle is to avoid thermal shock, which can crack the internal refractory lining. Do not open the furnace door until the internal temperature has fallen significantly, typically below 200°C, and ideally below 100°C for maximum safety and equipment longevity.

The goal of cooling a muffle furnace is not speed, but safety and preservation. Rapid cooling introduces thermal shock, which causes irreversible damage to the furnace's insulating chamber. A patient, natural cooldown is the only correct method.

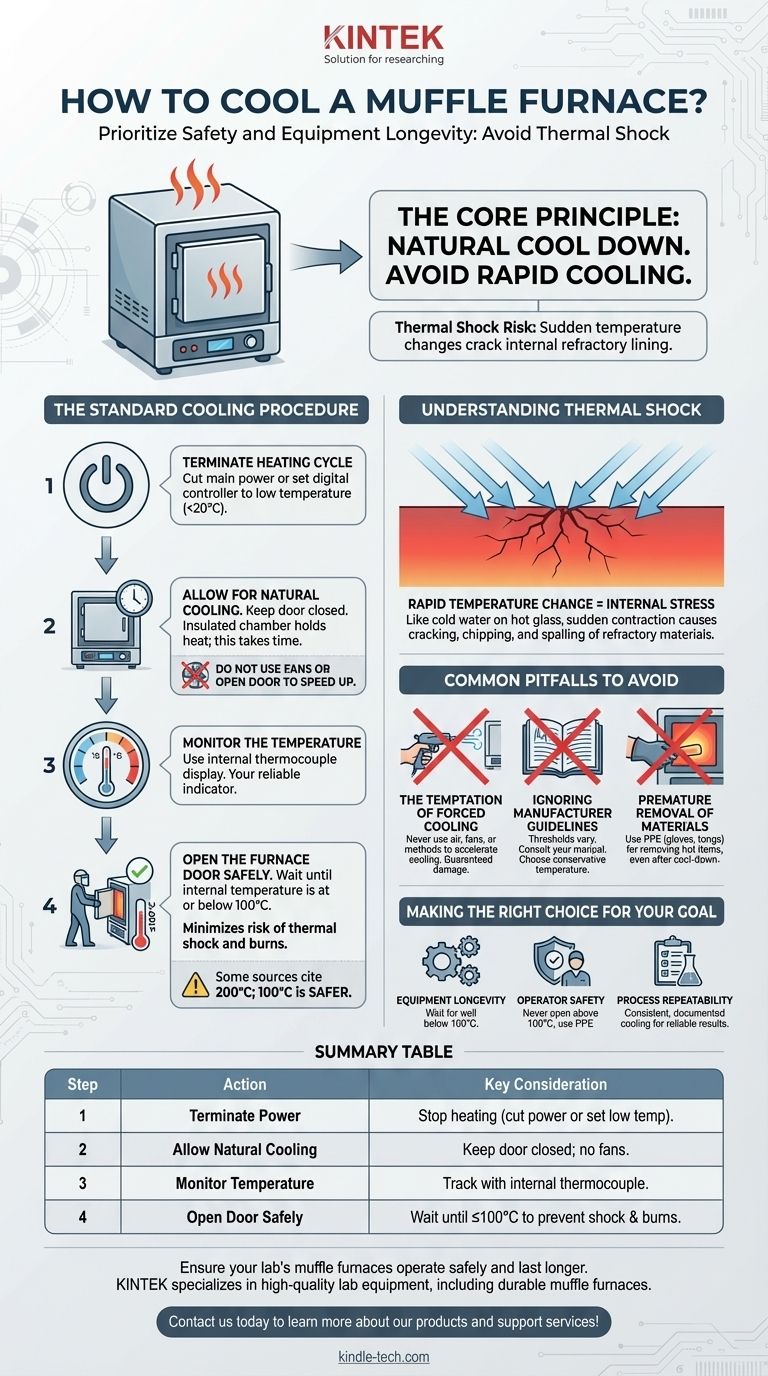

The Standard Cooling Procedure

Properly cooling your furnace is as critical as the heating cycle itself. Following these steps ensures the longevity of your equipment and the safety of the operator.

Step 1: Terminate the Heating Cycle

Depending on your model, this involves one of two actions. You can simply cut the main power supply to the unit, or you can use the digital controller to set the target temperature to a very low value (e.g., below 20°C) to stop the heating elements.

Step 2: Allow for Natural Cooling

The furnace must cool down on its own. The insulated chamber is designed to hold heat, so be aware that this process will take significantly longer than the initial heating phase.

Do not attempt to speed this up by opening the door a crack or using external fans. This is the primary cause of damage.

Step 3: Monitor the Temperature

Keep an eye on the furnace's temperature display. The thermocouple inside will provide an accurate reading of the internal chamber as it cools. This is your only reliable indicator of when it is safe to proceed.

Step 4: Open the Furnace Door Safely

Only open the furnace door when the temperature has dropped to a safe level. While some sources cite 200°C, a more conservative and safer best practice is to wait until it is at or below 100°C.

This lower threshold minimizes the risk of both thermal shock to the furnace and thermal burns to the operator.

Understanding the Critical "Why": Thermal Shock

Failing to follow the correct procedure has a direct and costly consequence: thermal shock. Understanding this phenomenon is key to appreciating the importance of patience.

What is Thermal Shock?

Thermal shock occurs when a material experiences a rapid change in temperature, causing different parts of the material to expand or contract at different rates. This creates immense internal stress.

Think of pouring cold water onto a hot glass baking dish. The sudden contraction where the water hits causes the glass to crack. The same principle applies to your furnace.

The Impact on Furnace Materials

The inside of a muffle furnace is lined with specialized ceramic refractory materials. These materials have excellent heat resistance but are often brittle.

When you open the door of a hot furnace, cool air rushes in and drastically lowers the surface temperature of the liner. This sudden contraction can cause cracking, chipping, and spalling, permanently degrading the furnace's performance and lifespan.

Common Pitfalls to Avoid

Adhering to best practices means actively avoiding common mistakes that operators make when rushed.

The Temptation of Forced Cooling

Never use compressed air, fans, or any other method to try and accelerate the cooling process. This is a guaranteed way to introduce thermal shock and damage the refractory lining.

Ignoring Manufacturer Guidelines

The temperature thresholds (200°C vs. 100°C) can vary slightly by model and the specific materials used in the furnace lining. Your equipment's manual is the definitive source of truth. When in doubt, always choose the more conservative (lower) temperature.

Premature Removal of Materials

Even after the door is opened, the crucible and its contents can remain extremely hot for a long time. Always use appropriate personal protective equipment (PPE), such as heat-resistant gloves and tongs, when removing items from a cooled furnace.

Making the Right Choice for Your Goal

Your approach to cooling should align with your primary objective for using the furnace.

- If your primary focus is equipment longevity: Always prioritize a slow, natural cool-down and wait until the temperature is well below 100°C before opening the door.

- If your primary focus is operator safety: Never open the furnace above 100°C and always use the proper tools and PPE for removing samples, even from a "cool" furnace.

- If your primary focus is process repeatability: A consistent, documented cooling procedure ensures that your samples are not affected by uncontrolled variables, leading to more reliable results.

Proper cooling is not an afterthought; it is a critical and non-negotiable part of the entire thermal process.

Summary Table:

| Step | Action | Key Consideration |

|---|---|---|

| 1 | Terminate Power | Stop heating by cutting power or setting controller to a low temperature (e.g., <20°C). |

| 2 | Allow Natural Cooling | Keep door closed; do not use fans or open the door to speed up the process. |

| 3 | Monitor Temperature | Use the furnace's internal thermocouple to track the cooldown. |

| 4 | Open Door Safely | Wait until internal temperature is at or below 100°C to prevent thermal shock and burns. |

Ensure your lab's muffle furnaces operate safely and last longer. Proper cooling is essential for protecting your investment and ensuring consistent results. KINTEK specializes in high-quality lab equipment, including durable muffle furnaces designed for reliable performance. Our experts can help you choose the right equipment and establish best practices for your laboratory. Contact us today to learn more about our products and support services!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Do muffle furnaces need to be vented? Essential Safety and Performance Guide

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- What temperature causes melting? Debinding vs. Melting in Metal Fabrication

- What is an example of quenching? Achieve Optimal Hardness with Precise Cooling

- What temperature does molten steel melt? Understand the Melting Range, Not a Single Point