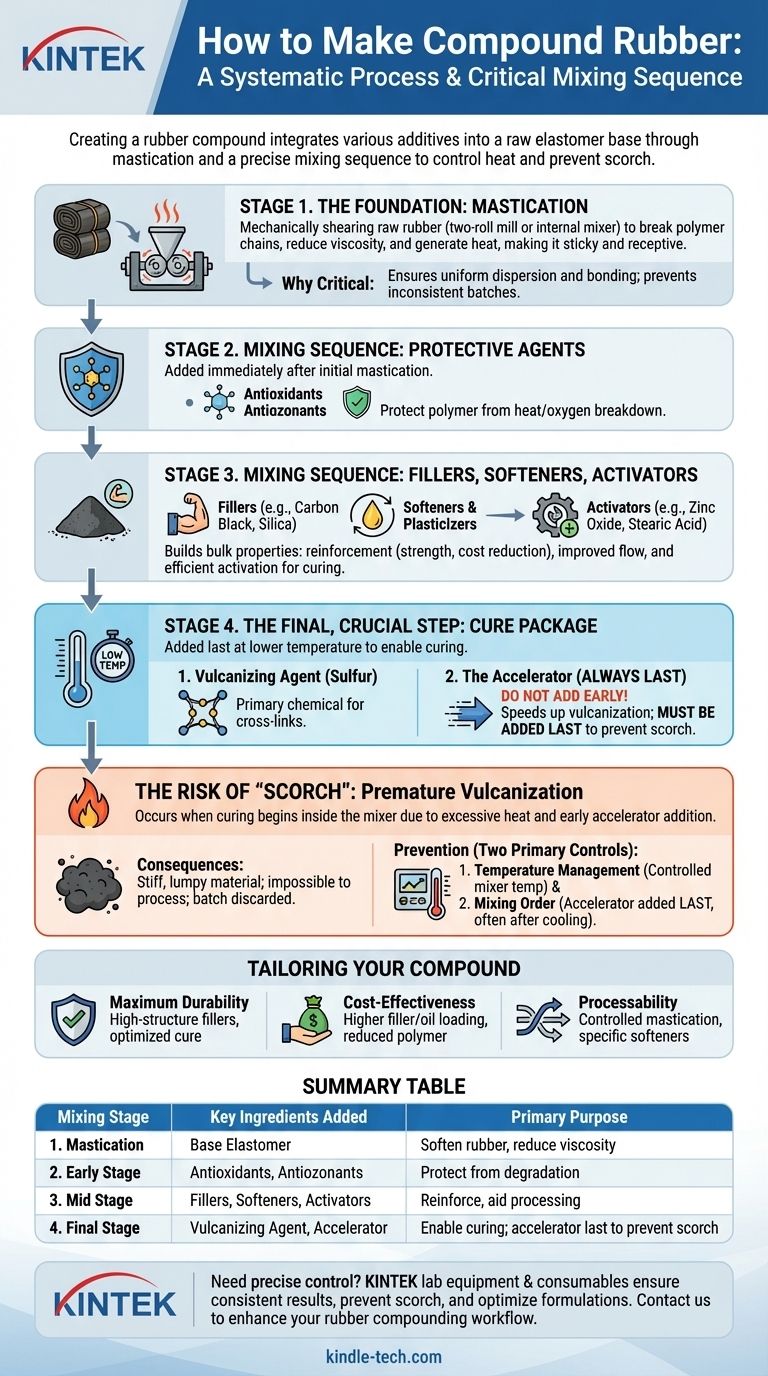

Creating a rubber compound is a systematic process of integrating various additives into a raw elastomer base. This is accomplished by mechanically mixing the rubber, a process known as mastication, and then introducing ingredients in a specific sequence: protective agents first, followed by fillers and softeners, and finally, the vulcanization chemicals that enable curing. The precise order is critical to achieving the desired properties and preventing premature hardening.

The sequence of mixing ingredients into rubber is not arbitrary. It is a carefully managed process designed to control heat, ensure uniform dispersion, and most importantly, prevent "scorch"—the premature curing of the rubber that renders a batch useless. The entire strategy revolves around adding the most heat-sensitive ingredient, the accelerator, last.

The Foundation: Preparing the Base Elastomer

The journey from a raw, tough polymer to a workable compound begins with a purely mechanical step. This initial stage prepares the rubber to accept the additives that will define its final characteristics.

What is Mastication?

Mastication is the process of mechanically shearing raw rubber, typically on a two-roll mill or in an internal mixer. Think of it as kneading a very tough dough. This action breaks down the long polymer chains, reducing the rubber's viscosity and internal resistance.

The process generates significant heat, which softens the rubber and makes it sticky and receptive to the other ingredients. Without this step, uniformly mixing in powders and oils would be nearly impossible.

Why Mastication is Critical

Proper mastication is the bedrock of good compounding. It ensures that the base rubber is in an optimal state to physically bond with fillers and chemically react with a cure system. An undermixed batch will be inconsistent, while an overmixed one can suffer from polymer degradation.

The Critical Mixing Sequence: Why Order Matters

Once the rubber is masticated, additives are introduced in a multi-stage process. The order is dictated by the function of each ingredient and its sensitivity to heat.

Step 1: Protective Agents

Immediately after initial mastication, antioxidants and antiozonants are mixed in. These chemicals are added early to protect the rubber polymer from breaking down due to the high heat and oxygen exposure during the rest of the mixing cycle and in its service life.

Step 2: Fillers, Softeners, and Activators

This stage builds the bulk of the compound's properties.

- Fillers, such as carbon black or silica, are added to reinforce the rubber, increasing its strength, tear resistance, and hardness. They also serve to reduce the overall cost.

- Softeners and Plasticizers, which are typically oils, are added to improve flow, reduce compound stiffness, and make processing easier.

- Activators, like zinc oxide and stearic acid, are also added here. They work to "activate" the vulcanization process later, making it much more efficient.

The Final, Crucial Step: The Cure Package

This is the most sensitive stage of mixing and is often done at a lower temperature. The cure package is what allows the rubber to transform from a soft, plastic-like material into a strong, elastic one.

It consists of two key components:

- The Vulcanizing Agent: Usually sulfur, this is the primary chemical that will form cross-links between the polymer chains. It can be added with the fillers, as it is not highly reactive on its own.

- The Accelerator: This chemical is always added last. Its job is to speed up the vulcanization reaction, allowing curing to occur at lower temperatures and in shorter times.

Understanding the Trade-offs: The Risk of "Scorch"

The entire mixing sequence is designed to mitigate one primary risk: scorch. Understanding this concept is fundamental to rubber compounding.

What is Scorch?

Scorch is the industry term for premature vulcanization. It occurs when the rubber begins to cure (cross-link) inside the mixer due to excessive heat and time.

This happens if the accelerator is added too early in the process, when the mixing temperatures are at their highest. The combination of heat and the accelerator initiates the curing reaction before the compound can be shaped into its final form.

The Consequences of Scorch

A scorched batch of rubber is a costly failure. The material becomes stiff, lumpy, and loses its plasticity, making it impossible to process further. It cannot be milled, extruded, or molded, and the entire batch must be discarded.

How to Prevent It

Preventing scorch is achieved through two primary controls:

- Temperature Management: Carefully controlling the temperature of the mixer throughout the cycle.

- Mixing Order: Reserving the accelerator for the very last step, often after letting the batch cool slightly, to ensure it is not exposed to peak mixing temperatures.

Making the Right Choice for Your Compound

The specific recipe and process you use will depend entirely on the intended application of the final product. By understanding the role of each ingredient, you can tailor the compound to meet your performance and processing needs.

- If your primary focus is maximum durability: You will prioritize high-structure reinforcing fillers like carbon black and a precisely optimized cure package.

- If your primary focus is cost-effectiveness: You may use higher loadings of less-expensive extender fillers and processing oils to reduce the proportion of raw polymer.

- If your primary focus is processability: You will carefully manage the mastication stage and use specific softeners to ensure the compound flows easily during molding or extrusion.

Mastering the compounding process is about controlling variables to achieve a predictable outcome, transforming a raw polymer into a high-performance engineered material.

Summary Table:

| Mixing Stage | Key Ingredients Added | Primary Purpose |

|---|---|---|

| 1. Mastication | Base Elastomer | Soften rubber, reduce viscosity for mixing |

| 2. Early Stage | Antioxidants, Antiozonants | Protect rubber from heat/oxygen degradation |

| 3. Mid Stage | Fillers (Carbon Black), Softeners, Activators | Reinforce rubber, aid processing |

| 4. Final Stage | Vulcanizing Agent (Sulfur), Accelerator | Enable curing; accelerator added last to prevent scorch |

Need precise control over your rubber compounding process? KINTEK specializes in high-quality lab equipment and consumables essential for rubber development and testing. From mixers to testing apparatus, our solutions help you achieve consistent results, prevent costly batch failures like scorch, and optimize your formulations. Let our experts support your laboratory's specific needs—contact us today to discuss how we can enhance your rubber compounding workflow.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is an internal screw mixer? A Guide to Gentle, Efficient Powder Blending

- What is a moulding machine used for? Automate Sand Casting for High-Quality Metal Parts

- What products can be made with injection molding? The Engine of Mass Production

- What is the role of high-speed melt mixing equipment? Key to RPE/CSPE Thermoplastic Elastomer Synthesis

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What is the difference between lamination and co-extrusion? Achieve Superior Material Performance

- How does a vulcanizing machine work? Mastering the Art of Rubber Transformation

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control