In certain scenarios, yes. Additive manufacturing is significantly cheaper than traditional methods for producing complex, low-volume parts because it eliminates the need for expensive tooling and molds. However, for simple parts produced at high volumes, traditional manufacturing remains the more cost-effective solution due to its superior speed and lower per-part cost at scale.

The question is not whether additive manufacturing is cheaper, but when it is cheaper. The cost-effectiveness of any manufacturing method is determined by the specific intersection of part complexity, production volume, and material requirements.

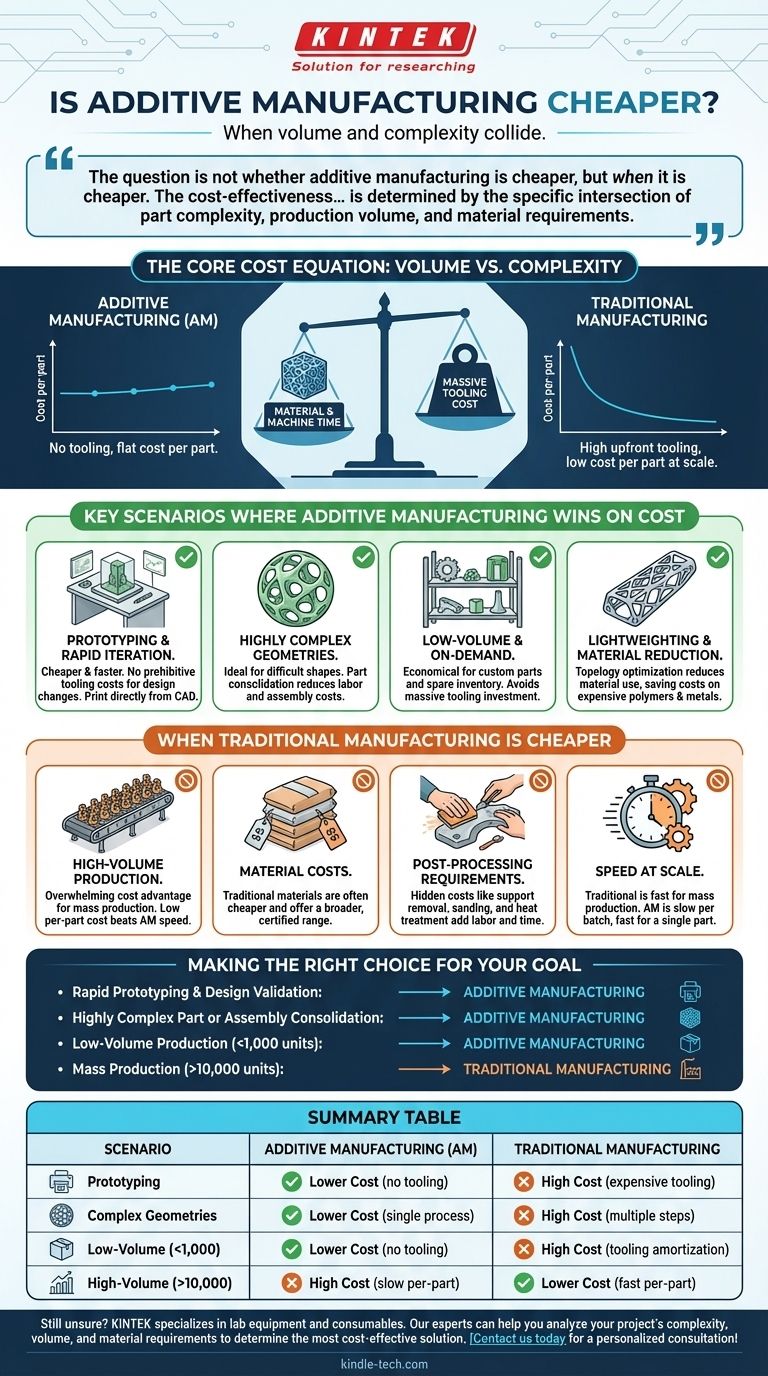

The Core Cost Equation: Volume vs. Complexity

To understand the cost difference, you must first understand the fundamental economic models of additive and traditional manufacturing. They are inverses of each other.

Additive Manufacturing (AM) Cost Model

In AM, the primary costs are material and machine time. There are virtually no initial setup or tooling costs beyond creating a digital file.

This means the cost to produce the first part is nearly identical to the cost to produce the thousandth part. The cost-per-part remains relatively high and flat, regardless of volume.

Traditional Manufacturing Cost Model

Methods like injection molding or casting have a massive upfront cost: the tooling (the mold or die). This can cost tens or even hundreds of thousands of dollars.

Once that tool is made, however, the cost to produce each individual part is extremely low—often mere pennies. The initial tooling cost is amortized, so the cost-per-part plummets as production volume increases.

Key Scenarios Where Additive Manufacturing Wins on Cost

AM's unique cost model makes it the clear economic winner in several specific applications.

Prototyping and Rapid Iteration

AM is almost always cheaper and faster for creating prototypes. The ability to print a single part directly from a CAD file, make a design change, and print another the same day avoids the prohibitive cost and delay of creating prototype tooling.

Highly Complex Geometries

If a part has features like internal lattice structures, organic shapes, or consolidated components, it can be difficult or impossible to produce with traditional methods.

AM can create these complex geometries in a single print. This process, known as part consolidation, can turn a multi-part assembly requiring labor and fasteners into a single, stronger, and cheaper component.

Low-Volume and On-Demand Production

For custom parts, jigs, fixtures, or spare part inventories, AM is ideal. It avoids the massive tooling investment that makes low-volume traditional manufacturing economically unviable.

This allows for on-demand production, reducing the need for costly physical inventory and warehousing.

Lightweighting and Material Reduction

AM enables topology optimization, a design process where software uses AI to remove any material not essential to a part's structural performance.

This creates highly optimized, lightweight parts that use significantly less material. When working with expensive materials like titanium or high-performance polymers, these material savings can be substantial.

Understanding the Trade-offs: When Traditional is Cheaper

Despite its advantages, AM is not a universal solution. In many cases, traditional methods hold a significant cost advantage.

High-Volume Production

This is the most critical factor. Once you need to produce tens of thousands or millions of identical parts, the economics overwhelmingly favor traditional manufacturing.

The low per-part cost of methods like injection molding or stamping will always beat AM's slower, more expensive per-part process at scale.

Material Costs

Materials specifically formulated for additive manufacturing are often more expensive per kilogram than the commodity resins and metals used in traditional processes.

Furthermore, the range of certified materials for traditional manufacturing remains far broader, offering more cost-effective options for less demanding applications.

Post-Processing Requirements

Many people overlook the hidden costs of post-processing for 3D printed parts. This can include support material removal, sanding, chemical smoothing, heat treatment, or machining to achieve final tolerances.

These secondary steps add significant labor and time, increasing the final part cost, especially for metal components.

Speed at Scale

While AM is fast for a single part, it is slow for mass production. An injection molding machine can produce a small part every few seconds. An AM machine might take several hours to produce a single batch of the same parts.

Making the Right Choice for Your Goal

To determine the most cost-effective method, analyze your project's specific needs.

- If your primary focus is rapid prototyping and design validation: Choose additive manufacturing for its unmatched speed and low initial cost.

- If your primary focus is producing a highly complex part or consolidating an assembly: Additive manufacturing is likely cheaper and may be the only feasible option.

- If your primary focus is low-volume production (e.g., under 1,000 units): Additive manufacturing is a strong contender, often beating the tooling cost of traditional methods.

- If your primary focus is mass production (e.g., over 10,000 units): Traditional manufacturing is almost certainly the more cost-effective path.

By analyzing your project through the lens of volume and complexity, you can confidently select the manufacturing process that delivers the best economic value.

Summary Table:

| Scenario | Additive Manufacturing (AM) | Traditional Manufacturing |

|---|---|---|

| Prototyping | Lower Cost (no tooling) | High Cost (expensive tooling) |

| Complex Geometries | Lower Cost (single process) | High Cost (multiple steps) |

| Low-Volume (<1,000 units) | Lower Cost (no tooling) | High Cost (tooling amortization) |

| High-Volume (>10,000 units) | High Cost (slow per-part) | Lower Cost (fast per-part) |

Still unsure which manufacturing method is right for your project? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your part's complexity, volume, and material requirements to determine the most cost-effective solution—whether it's additive or traditional manufacturing. Contact us today for a personalized consultation and optimize your production process!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What is the principle of DC magnetron sputtering? Achieve Fast, High-Quality Thin Film Deposition

- What role do laboratory drying ovens play in sugarcane bagasse pyrolysis? Enhance Bio-oil Quality & GCV

- What is the role of a magnetic stirrer in Zn-Based Zeolite prep? Maximize Ion Exchange and Homogeneity

- Is deposition physical or chemical? Unraveling the Science of Phase Transitions

- What role does a laboratory drying oven play in the processing and chemical analysis of aluminum dross?

- What temperature does quartz glass melt at? Understanding Its Softening Point and Practical Limits

- What is used as a source of heat in the laboratory? Choose the Right Tool for Safe & Precise Heating

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research