In a technical context, an autoclave is definitively classified as a piece of equipment. While it contains instruments like pressure gauges and temperature sensors to monitor its process, its primary function is not to measure but to perform a task—sterilization. Therefore, the overall system is considered equipment.

The core distinction is one of function. Instruments are primarily used to measure, observe, or control, while equipment refers to the machinery used to perform a specific process or task. An autoclave performs the process of sterilization.

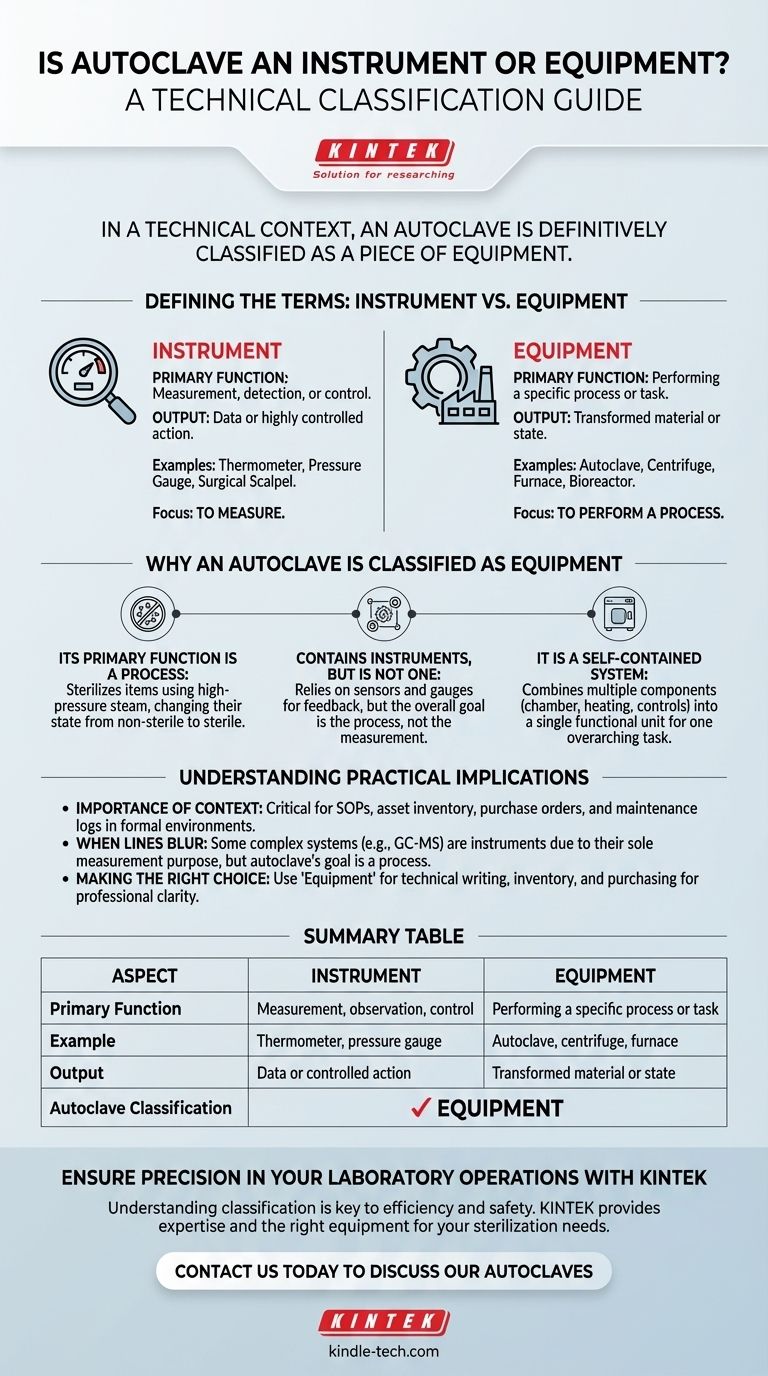

Defining the Terms: Instrument vs. Equipment

To understand why an autoclave fits squarely in one category, we must first establish clear, functional definitions for both terms. In a scientific or industrial setting, these words have specific meanings.

The Role of an Instrument

An instrument is a tool or device used for a precise purpose, typically related to measurement, detection, or control. Its main output is data or a highly controlled action.

Think of a thermometer, a pH meter, or a pressure gauge. Their sole job is to measure a physical property and report it. Even a surgical scalpel is an instrument because it's used for precise manipulation.

The Role of Equipment

Equipment is a broader term referring to a set of tools, machinery, and devices needed to carry out a particular process or job. It is task-oriented.

A laboratory centrifuge, a furnace, or a bioreactor are all examples of equipment. They take an input, perform a complex process, and produce a transformed output.

Why an Autoclave is Classified as Equipment

Applying these definitions, the classification for an autoclave becomes clear and logical.

Its Primary Function is a Process

The fundamental purpose of an autoclave is to sterilize items using high-pressure steam. It actively changes the state of the objects placed inside it, moving them from non-sterile to sterile. This is a classic example of a machine designed to execute a process.

It Contains Instruments, But is Not One

An autoclave relies on several instruments to function correctly, such as temperature sensors, pressure gauges, and timers.

However, these are subordinate components. Their role is to provide feedback and control to the larger system. The equipment's main purpose isn't to tell you the temperature; its purpose is to use a specific temperature and pressure to achieve sterilization.

It Is a Self-Contained System

An autoclave is a complete, self-contained system built for one overarching task. It combines multiple components (a pressure chamber, heating elements, safety valves, and control instruments) into a single functional unit. This system-level view firmly places it in the "equipment" category.

Understanding the Practical Implications

While this may seem like a minor semantic point, using the correct terminology is critical in professional environments. The distinction impacts purchasing, maintenance, and documentation.

The Importance of Context

In casual conversation, the terms might be used interchangeably without causing confusion. No one will fault you for misspeaking.

However, in formal or technical contexts, precision matters. Standard Operating Procedures (SOPs), asset inventory lists, purchase orders, and maintenance logs all require accurate and consistent terminology.

When the Lines Can Blur

Some highly complex systems can blur the lines. For example, a Gas Chromatograph-Mass Spectrometer (GC-MS) is a massive piece of machinery (equipment) that is almost always referred to as an analytical instrument, because its sole purpose is measurement.

In these cases, the machine's ultimate goal (measurement vs. process) remains the deciding factor. Since the autoclave's goal is a process (sterilization), it remains equipment.

Making the Right Choice for Your Goal

Use this distinction to communicate with clarity and precision in your work.

- If your primary focus is inventory management or technical writing: Always classify an autoclave as equipment to ensure your documentation is accurate and standardized.

- If your primary focus is purchasing or facility planning: Referring to it as equipment ensures you are searching in the correct category for industrial-grade machinery and allocating appropriate space and resources.

- If your primary focus is general lab communication: While equipment is the more precise term, your colleagues will understand what you mean in informal discussion, but adopting the correct term is always best practice.

Ultimately, distinguishing between instruments and equipment allows you to operate with a higher level of professional clarity.

Summary Table:

| Aspect | Instrument | Equipment |

|---|---|---|

| Primary Function | Measurement, observation, control | Performing a specific process or task |

| Example | Thermometer, pressure gauge | Autoclave, centrifuge, furnace |

| Output | Data or controlled action | Transformed material or state |

| Autoclave Classification | ✓ Equipment |

Ensure Precision in Your Laboratory Operations with KINTEK

Understanding the correct classification of your lab tools is the first step toward optimal efficiency and safety. As a leading provider of laboratory equipment and consumables, KINTEK helps you make informed decisions.

Whether you are setting up a new lab, expanding your capabilities, or need reliable support for your sterilization processes, our expertise ensures you get the right equipment for your specific needs.

Contact us today to discuss how our autoclaves and other laboratory solutions can enhance your workflow, ensure compliance, and deliver consistent, reliable results.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is an autoclave used for the Hydrogen Disbonding Test? Ensuring 5Cr-0.5Mo Steel Cladding Integrity

- Is a retort a pressure vessel? The Critical Safety Classification for Your Sterilization Process

- Why must Ni-Cr alloy and carbon-coated samples be treated in a pressure steam autoclave? Ensure Data Integrity

- Why is a pressure steam sterilizer necessary for laboratory equipment? Ensure Accuracy in Disinfection Research

- What is an autoclave used for in a lab? Achieve Total Sterilization for Lab Safety and Integrity

- How do you sterilize medical equipment in an autoclave? A Guide to a Fail-Safe Process

- How long does a typical autoclave run? Understand the Full Cycle for Safe Sterilization

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety