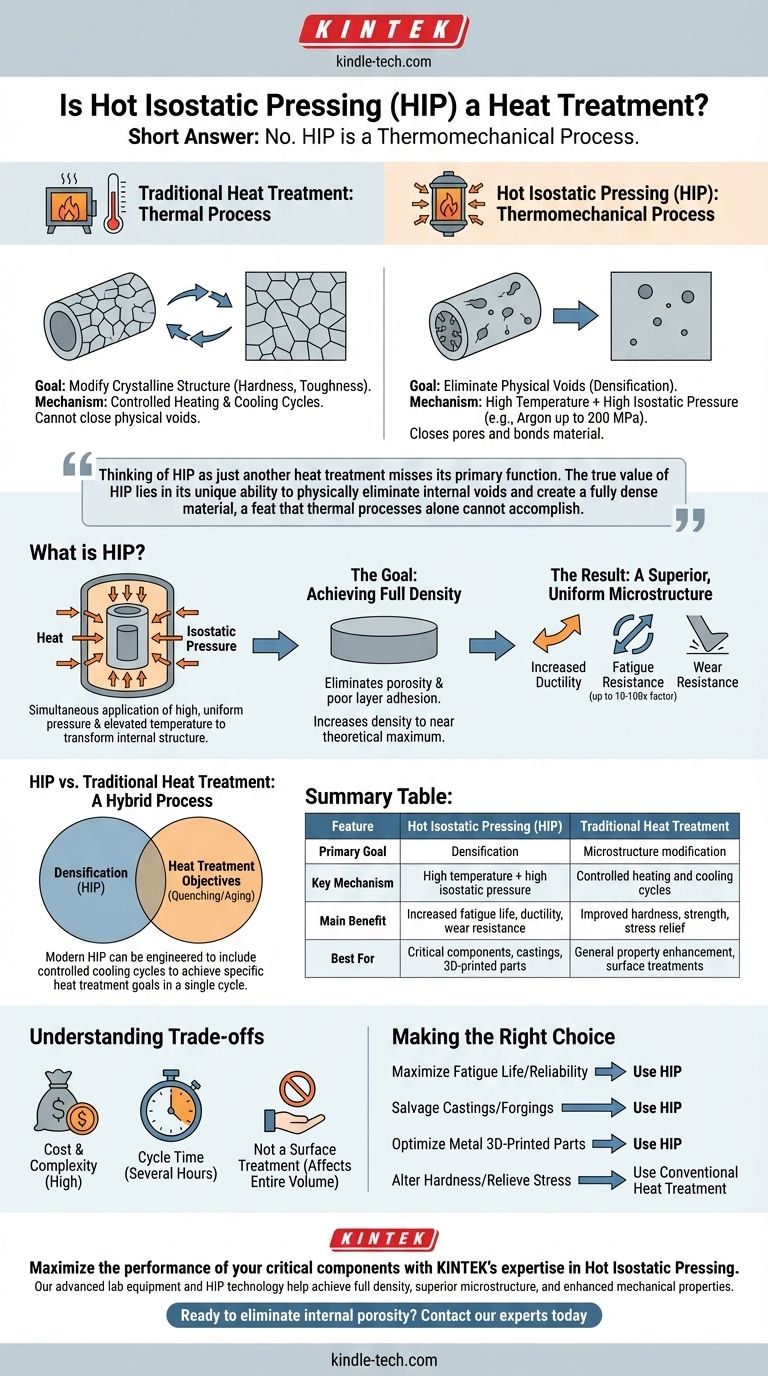

In short, Hot Isostatic Pressing (HIP) is best understood as a thermomechanical process, not purely a heat treatment. While it involves the high temperatures characteristic of heat treatment, its defining feature is the simultaneous application of high, uniform pressure. This combination allows HIP to achieve results that heat treatment alone cannot, primarily the elimination of internal porosity to densify a material.

Thinking of HIP as just another heat treatment misses its primary function. The true value of HIP lies in its unique ability to physically eliminate internal voids and create a fully dense material, a feat that thermal processes alone cannot accomplish.

What is Hot Isostatic Pressing?

Hot Isostatic Pressing is a manufacturing process that subjects a component to both elevated temperature and high-pressure gas. This combination fundamentally transforms the material's internal structure.

The Core Mechanism: Heat and Pressure

The process takes place inside a sealed, high-pressure containment vessel. A component is heated to a high temperature, making the material soft and malleable on a microscopic level.

Simultaneously, an inert gas, typically argon, is pumped into the vessel, creating immense and uniform (isostatic) pressure on the component from all directions. This pressure can reach up to 200 MPa, or nearly 30,000 psi.

The Goal: Achieving Full Density

The primary purpose of HIP is to eliminate internal microscopic voids, such as porosity in castings or poor layer adhesion in 3D-printed metal parts.

The combination of heat and pressure effectively squeezes the material together, causing these internal voids to collapse and weld shut. This increases the material's density to near its theoretical maximum.

The Result: A Superior, Uniform Microstructure

By removing the internal defects that act as stress concentrators, HIP dramatically improves a material's mechanical properties.

Key benefits include a significant increase in ductility, fatigue resistance, and wear resistance. For some components, HIP can increase fatigue life by a factor of 10 to 100.

How HIP Differs from Traditional Heat Treatment

While both processes use heat to modify material properties, their fundamental goals and mechanisms are distinct. Understanding this difference is crucial for proper application.

Heat Treatment's Focus: Modifying Crystalline Structure

Traditional heat treatment processes like annealing, quenching, or aging use controlled heating and cooling cycles to alter a material's microstructure.

The goal is to change properties like hardness, toughness, or internal stress by rearranging the crystalline grain structure. However, these processes cannot close physical voids.

HIP's Focus: Eliminating Physical Voids

HIP's primary function is densification. The applied pressure is the key ingredient that physically closes pores and bonds material across internal surfaces.

While the heat involved does cause microstructural changes similar to heat treatment, the pressure-induced densification is a distinct and powerful effect.

A Hybrid Process

In many modern applications, HIP is used to consolidate manufacturing steps. The process can be engineered to include controlled cooling cycles that achieve specific heat treatment objectives, such as quenching or aging, all within a single HIP cycle.

This makes it a hybrid process that combines densification and heat treatment, reducing overall production time and improving part quality.

Understanding the Trade-offs

While powerful, HIP is a specialized process with specific considerations. It is not a universal solution for all material improvement needs.

Cost and Complexity

HIP equipment is expensive to acquire and operate. The process is significantly more complex than a standard atmosphere furnace heat treatment, making it best suited for high-value or performance-critical components.

Cycle Time

A HIP cycle can take several hours to complete, which includes heating, soaking at temperature and pressure, and cooling. This can be a bottleneck in high-volume production if not planned for.

It's Not a Surface Treatment

HIP affects the entire volume of a component. It is not a surface hardening process like carburizing or nitriding. If only surface properties need to be enhanced, other methods may be more cost-effective.

Making the Right Choice for Your Goal

The decision to use HIP depends entirely on your material, its initial condition, and your final performance requirements.

- If your primary focus is maximizing fatigue life and reliability in critical components: Use HIP to eliminate the microscopic voids that act as initiation points for cracks.

- If your primary focus is salvaging high-value castings or forgings with internal porosity: Use HIP as a post-processing step to achieve near-perfect density and recover the component's mechanical integrity.

- If your primary focus is optimizing metal 3D-printed parts for demanding applications: Use HIP to fuse layers, eliminate porosity, and create a uniform microstructure far superior to the as-printed state.

- If your primary focus is simply altering hardness or relieving internal stress: A conventional heat treatment process is likely the more direct and cost-effective solution.

By understanding HIP as a powerful densification process that incorporates heat, you can deploy it precisely where its unique benefits will deliver the greatest impact.

Summary Table:

| Feature | Hot Isostatic Pressing (HIP) | Traditional Heat Treatment |

|---|---|---|

| Primary Goal | Densification: Eliminate internal porosity | Microstructure modification: Alter hardness, toughness |

| Key Mechanism | High temperature + high isostatic pressure | Controlled heating and cooling cycles |

| Main Benefit | Increased fatigue life, ductility, and wear resistance | Improved hardness, strength, or stress relief |

| Best For | Critical components, castings, 3D-printed parts | General property enhancement, surface treatments |

Maximize the performance of your critical components with KINTEK's expertise in Hot Isostatic Pressing.

At KINTEK, we specialize in advanced lab equipment and consumables, including HIP solutions tailored for laboratories and manufacturers. Whether you're working with high-value castings, metal 3D-printed parts, or performance-critical components, our HIP technology can help you achieve full density, superior microstructure, and enhanced mechanical properties.

Ready to eliminate internal porosity and boost your material's fatigue life? Contact our experts today to discuss how HIP can transform your materials and meet your specific laboratory needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What are the parameters of hot isostatic pressing? Master Temperature, Pressure & Time for Full Densification

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density

- What are the disadvantages of hot isostatic pressing? The High Cost of Superior Material Performance

- What is the temperature and pressure for hot isostatic pressing? Achieve 100% Dense, High-Performance Materials

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- What is the primary function of Hot Isostatic Pressing (HIP) equipment? Achieve Peak Density in IN718 Superalloys

- Why is a SUS304 stainless steel capsule used to encapsulate IN718 powder? Key Benefits for HIP Processing

- How does hot isostatic pressing work? Achieve Full Density and Superior Material Performance