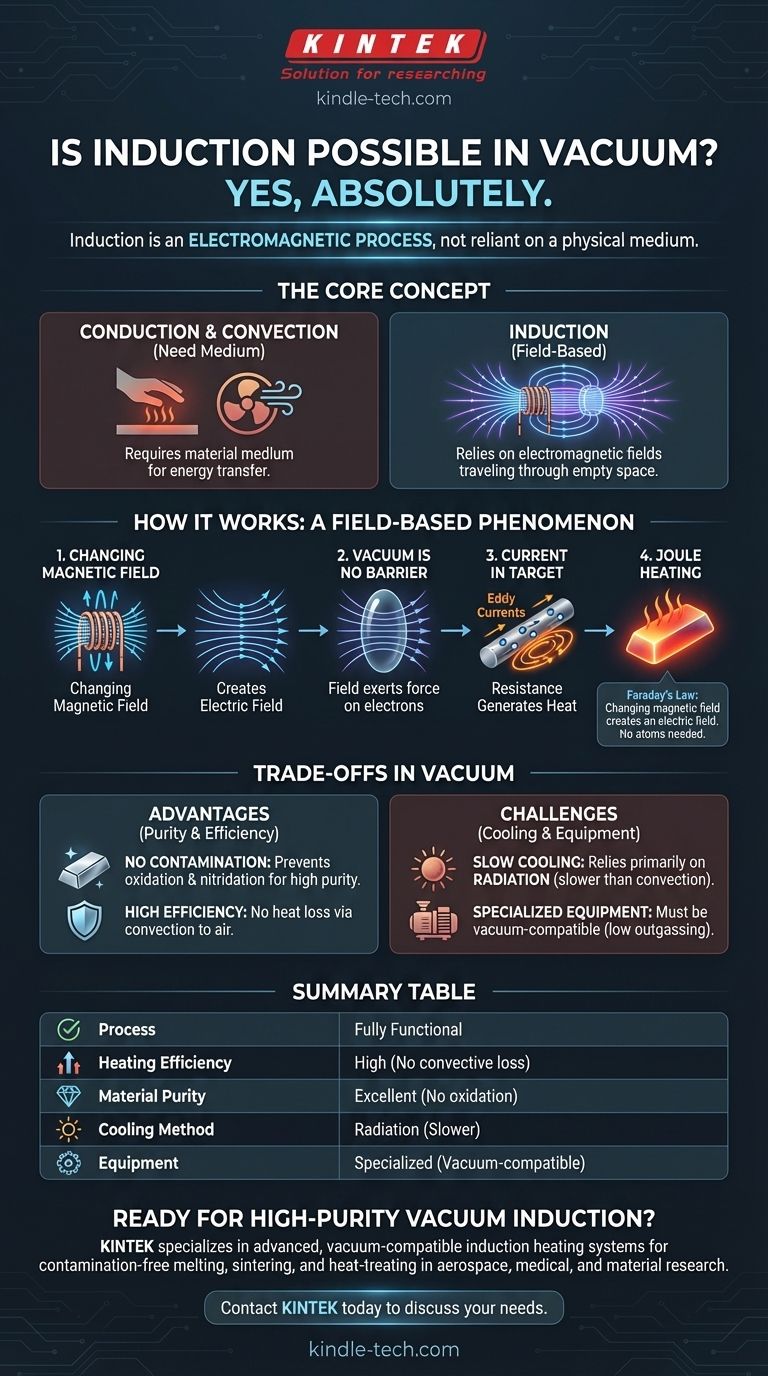

Yes, absolutely. Induction is fundamentally an electromagnetic process that relies on changing magnetic fields. These fields do not require a physical medium like air or water to exist or propagate, and therefore function perfectly in the vacuum of space.

The core of this concept is distinguishing how different forms of energy travel. While heat transfer methods like conduction and convection need a material medium, induction relies on invisible electromagnetic fields, which, just like light and radio waves, travel effortlessly through a vacuum.

How Induction Works: A Field-Based Phenomenon

To understand why a vacuum poses no barrier to induction, we must first look at the mechanism itself. It is not about a substance traveling from point A to point B; it is about the influence of a field.

The Role of the Magnetic Field

At its heart, induction is described by Faraday's Law of Induction. This law states that a changing magnetic field creates an electric field. This is a fundamental principle of the universe.

The magnetic field is a distortion of spacetime itself. It does not need atoms or molecules to support it. Therefore, an induction coil can create its changing magnetic field just as effectively in a vacuum as it can in air.

Creating the Current in the Target

The electric field created by the changing magnetic field is what does the work. When a conductive material (like a piece of metal) is placed within this field, the field exerts a force on the free electrons inside the metal.

This force causes the electrons to move, creating an electrical current. The vacuum is simply the empty space between the coil generating the field and the metal object experiencing its effects.

The Specific Case of Induction Heating

Induction heating is a direct application of this principle. The induced electrical currents, often called eddy currents, flow through the material.

Because every real material has some electrical resistance, the flow of this current generates heat—a phenomenon known as Joule heating. The process is highly efficient in a vacuum because there is no air to carry the heat away.

Understanding the Trade-offs of Induction in a Vacuum

Using induction in a vacuum is a common industrial practice, particularly in metallurgy. However, it comes with a specific set of advantages and challenges.

Advantage: Purity and Efficiency

The primary benefit of performing induction heating in a vacuum is preventing contamination. At high temperatures, metals can react with oxygen and nitrogen in the air, forming unwanted oxides and nitrides.

A vacuum eliminates this possibility, which is critical for creating high-purity alloys used in aerospace and medical applications. It also prevents heat loss via convection, making the process more energy-efficient.

Challenge: Heat Removal

The same factor that improves heating efficiency—the lack of air—also complicates cooling. You cannot simply blow air on the object to cool it down.

Cooling in a vacuum relies primarily on radiation, where the object radiates its heat away as infrared light. This can be a much slower process than convective cooling.

Challenge: Equipment and Materials

All equipment used inside the vacuum chamber, including the induction coil and its supports, must be vacuum-compatible. This means the materials cannot release trapped gases when heated (a process called "outgassing"), as this would ruin the vacuum. This requirement adds complexity and cost to the system design.

Making the Right Choice for Your Goal

Understanding this principle allows you to apply it to specific goals, from industrial manufacturing to fundamental physics.

- If your primary focus is high-purity material processing: Vacuum induction is the definitive method for melting and casting reactive metals and superalloys without atmospheric contamination.

- If your primary focus is clean and efficient heating: A vacuum environment is ideal because it eliminates heat loss to the surrounding air and prevents surface oxidation.

- If your primary focus is understanding physics: Realizing that electromagnetic fields are independent of a medium is the key to grasping everything from how transformers work to how the sun heats the Earth.

Ultimately, induction's ability to function in a vacuum is a direct consequence of the fundamental, medium-independent nature of electromagnetic fields.

Summary Table:

| Aspect | Status in Vacuum | Key Consideration |

|---|---|---|

| Induction Process | Fully Functional | Electromagnetic fields propagate freely. |

| Heating Efficiency | High | No convective heat loss to surrounding air. |

| Material Purity | Excellent | Prevents oxidation and nitridation. |

| Cooling Method | Radiation | Slower than convective cooling in air. |

| Equipment | Requires Specialization | Must use vacuum-compatible, low-outgassing materials. |

Ready to achieve high-purity material processing with vacuum induction?

KINTEK specializes in advanced lab equipment, including vacuum-compatible induction heating systems. Our solutions are designed for researchers and industries that demand contamination-free environments for melting, sintering, and heat-treating reactive metals and superalloys.

We provide the reliable technology and expert support to enhance your lab's capabilities in aerospace, medical, and advanced materials development.

Contact KINTEK today to discuss your specific vacuum induction needs and discover the right solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds