Yes, Physical Vapor Deposition (PVD) is an exceptionally good coating process, widely regarded as a superior method for applying a thin, durable, and high-performance film onto a surface. It creates a finish that is significantly harder and more resistant to corrosion and wear than traditional coating methods like electroplating or painting, all while being an environmentally responsible process.

PVD is not merely a coating; it is a high-performance surface engineering technology. Its "goodness" is a function of its specific application, where its superior durability and finish must justify its higher cost and process complexity compared to more conventional alternatives.

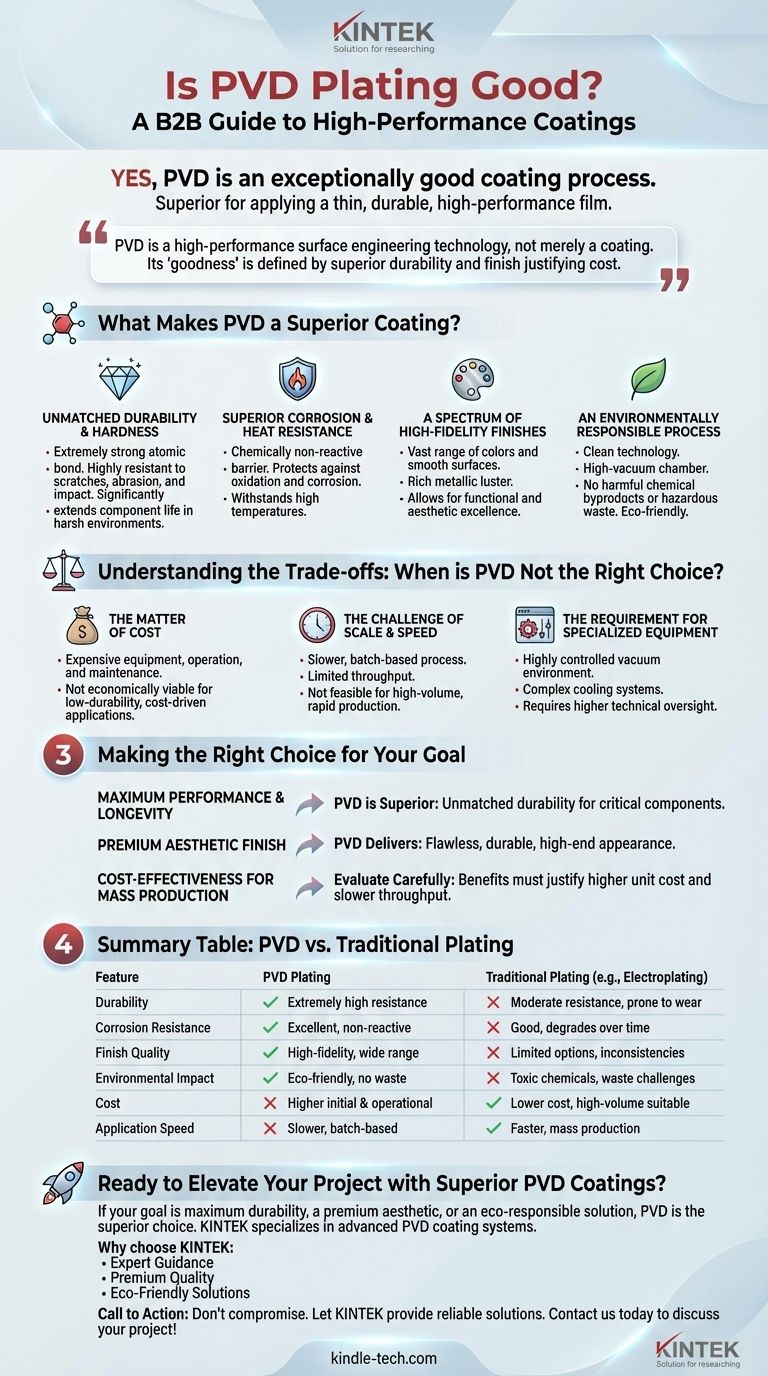

What Makes PVD a Superior Coating?

PVD stands out because the process fundamentally changes the surface of an object at a molecular level. It involves vaporizing a solid material in a vacuum and depositing it atom by atom onto a substrate, creating an incredibly strong and uniform bond.

Unmatched Durability and Hardness

The bond created during the PVD process is extremely strong. This results in a finish that is highly resistant to scratches, abrasion, and impact.

PVD coatings significantly extend the life of components by improving their hardness and wear resistance, allowing them to function in harsh environments where uncoated parts would quickly fail.

Superior Corrosion and Heat Resistance

PVD films act as a chemically non-reactive barrier, protecting the underlying material from oxidation and corrosion. This makes it ideal for components exposed to the elements or corrosive substances.

Furthermore, these coatings can withstand high temperatures without degrading, a crucial attribute for high-performance mechanical parts and tools.

A Spectrum of High-Fidelity Finishes

Unlike many industrial coatings, PVD offers a vast range of color and finish options. The process can deposit various materials, resulting in a fine, smooth surface with a rich metallic luster.

This versatility allows for both functional and aesthetic excellence, making it a favorite for premium consumer goods and architectural hardware where appearance is as important as durability.

An Environmentally Responsible Process

PVD is a clean technology. Because it occurs in a high-vacuum chamber, it produces no harmful chemical byproducts or hazardous waste.

This makes it a far more environmentally friendly alternative to traditional processes like electroplating, which often involve toxic chemical baths and create significant disposal challenges.

Understanding the Trade-offs: When is PVD Not the Right Choice?

While PVD offers remarkable benefits, it is not the universal solution for every coating need. Its advanced nature comes with specific requirements and limitations that make it unsuitable for certain applications.

The Matter of Cost

The primary barrier to PVD is its cost. The sophisticated vacuum deposition equipment is expensive to acquire, operate, and maintain.

For applications where cost is the main driver and the highest levels of durability are not required, traditional painting or electroplating may be a more economically viable choice.

The Challenge of Scale and Speed

PVD is an inherently slower, batch-based process. The rate of deposition is measured in micrometers per hour, and the size of the vacuum chamber limits the volume of parts that can be coated at one time.

This can limit its feasibility for high-volume, low-margin products that require a rapid production rate.

The Requirement for Specialized Equipment

Effective PVD coating requires a highly controlled environment. This includes not only the vacuum chamber itself but also a reliable and powerful cooling system to manage the heat generated during the process.

The complexity and routine maintenance of this equipment demand a higher level of technical oversight than simpler coating methods.

Making the Right Choice for Your Goal

To determine if PVD is "good" for you, you must align its capabilities with your project's primary objective.

- If your primary focus is maximum performance and longevity: PVD is the superior choice, providing unmatched durability, hardness, and corrosion resistance for critical components.

- If your primary focus is a premium aesthetic finish: PVD delivers a flawless, high-end appearance in a wide variety of colors that is far more durable than other decorative coatings.

- If your primary focus is cost-effectiveness for mass production: You must carefully evaluate if PVD's benefits justify its higher unit cost and slower throughput compared to traditional coating methods.

Ultimately, choosing PVD is a strategic decision to invest in quality, performance, and longevity for applications that demand it.

Summary Table:

| Feature | PVD Plating | Traditional Plating (e.g., Electroplating) |

|---|---|---|

| Durability | Extremely high scratch and wear resistance | Moderate resistance, more prone to wear |

| Corrosion Resistance | Excellent, acts as a non-reactive barrier | Good, but can degrade over time |

| Finish Quality | High-fidelity, wide range of colors and metallic lusters | Limited color options, may have inconsistencies |

| Environmental Impact | Eco-friendly, no hazardous waste | Often involves toxic chemicals and waste |

| Cost | Higher initial and operational cost | Lower cost, more suitable for high-volume production |

| Application Speed | Slower, batch-based process | Faster, better for mass production |

Ready to Elevate Your Project with Superior PVD Coatings?

If your goal is to achieve maximum durability, a premium aesthetic finish, or an environmentally responsible coating solution, PVD plating is the superior choice. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including advanced PVD coating systems tailored to your specific needs.

Why choose KINTEK for your PVD requirements?

- Expert Guidance: Our team helps you determine if PVD is the right fit for your application, ensuring optimal performance and cost-efficiency.

- Premium Quality: We deliver coatings that enhance hardness, corrosion resistance, and longevity for critical components.

- Eco-Friendly Solutions: Our PVD processes are clean and sustainable, aligning with modern environmental standards.

Don't compromise on quality—let KINTEK provide the reliable, high-performance coating solutions your laboratory deserves. Contact us today to discuss your project and discover how our PVD expertise can benefit you!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition