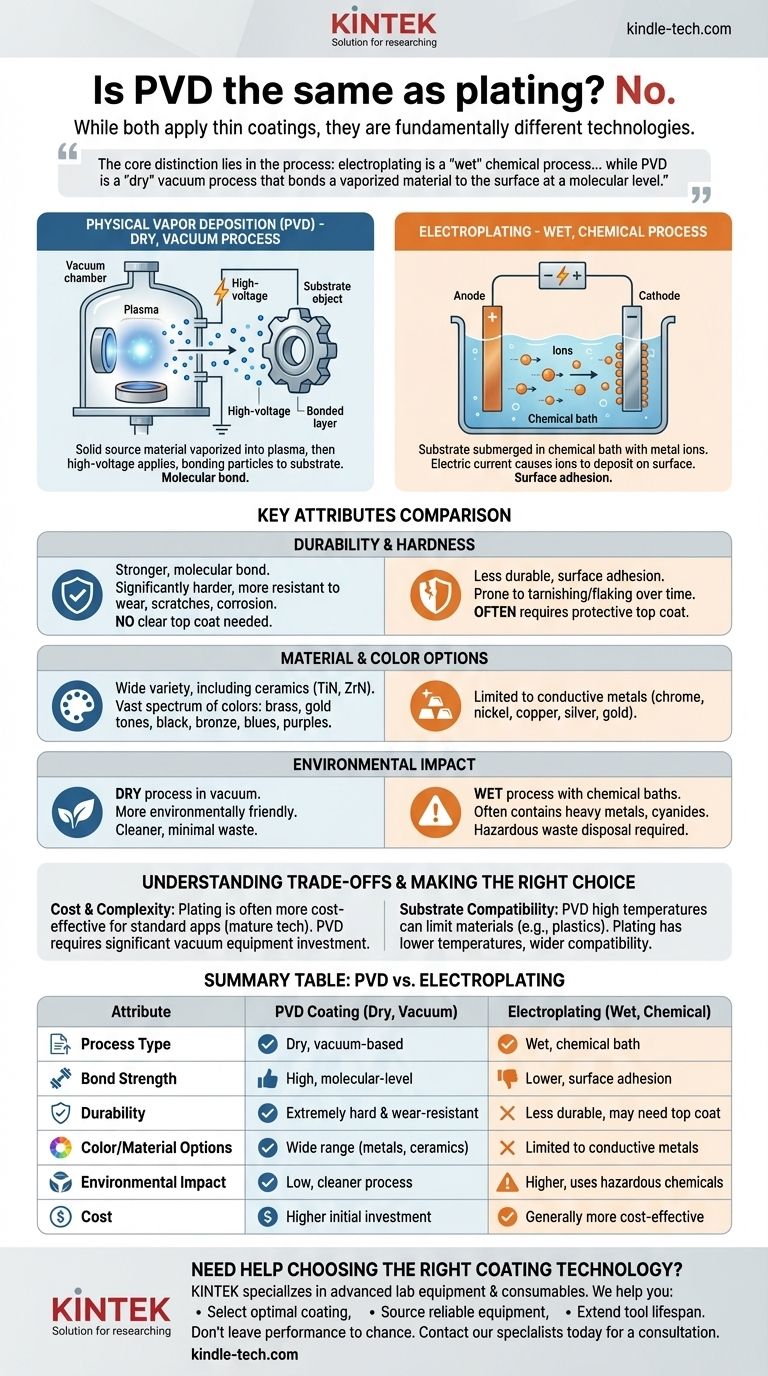

In short, no. While both Physical Vapor Deposition (PVD) and electroplating are processes used to apply a thin coating to a surface, they are fundamentally different technologies. They differ in the application method, the materials used, and the final characteristics of the coating itself.

The core distinction lies in the process: electroplating is a "wet" chemical process using an electric current in a liquid bath, while PVD is a "dry" vacuum process that bonds a vaporized material to the surface at a molecular level.

The Core Distinction: How Each Process Works

To understand why they are not the same, it's essential to look at the mechanics of each method. Their foundational principles are entirely different.

Understanding Electroplating

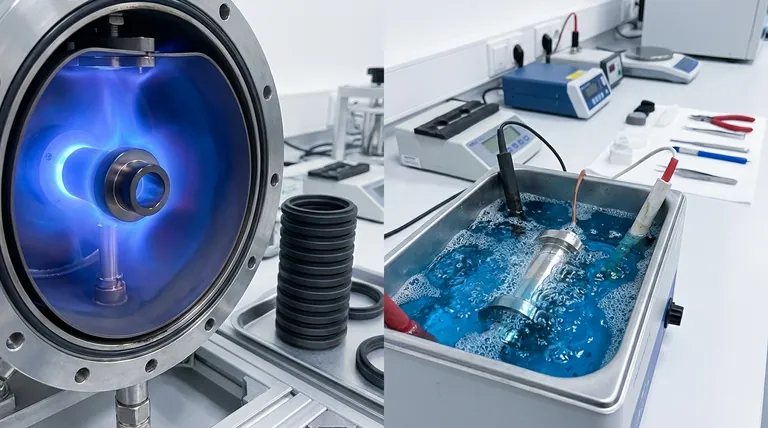

Electroplating is a classic chemical process. It involves submerging the object to be coated (the substrate) into a liquid chemical bath containing dissolved metal ions.

An electrical current is passed through the bath, causing the metal ions to deposit onto the surface of the object, forming a thin, uniform metallic layer. This is the traditional method for creating chrome bumpers or gold-plated jewelry.

Understanding Physical Vapor Deposition (PVD)

PVD is a more modern, high-tech process that takes place inside a high-vacuum chamber.

First, a solid source material (such as titanium or zirconium) is vaporized into a plasma of atoms or molecules. Then, a high-voltage charge is applied to the object, causing these vaporized particles to be physically drawn to and deposited onto its surface, forming a dense and strongly bonded film.

Comparing Key Attributes: PVD vs. Electroplating

The differences in process lead to significant differences in performance, appearance, and application.

Durability and Hardness

PVD coatings form a much stronger, molecular bond with the substrate. This results in a finish that is significantly harder and more resistant to wear, scratches, and corrosion than most traditional plating.

As a result, PVD coatings do not require a clear top coat to protect them, unlike many plated finishes which can be prone to tarnishing or flaking over time.

Material and Color Options

Electroplating is generally limited to conductive metals like chrome, nickel, copper, silver, and gold.

PVD, however, can be used with a much wider variety of materials, including ceramics (like titanium nitride or zirconium nitride). This versatility allows for a vast spectrum of colors, from brass and gold tones to black, bronze, and even blues and purples.

Environmental Impact

PVD is a dry process that occurs in a sealed vacuum. It is widely considered more environmentally friendly than electroplating, which relies on chemical baths that often contain heavy metals and cyanides, producing hazardous waste that requires careful disposal.

Understanding the Trade-offs

Neither technology is universally superior; the right choice depends on balancing performance requirements against other factors.

Cost and Complexity

Traditional electroplating is a mature, well-established technology. For many standard applications, it can be more cost-effective than PVD, which requires significant capital investment in vacuum chamber equipment.

Substrate Compatibility

The high temperatures used in some PVD processes can limit the types of materials that can be coated. Low-melting-point plastics, for instance, are generally not suitable for PVD.

Electroplating is often performed at much lower temperatures, making it compatible with a wider range of temperature-sensitive substrates.

Making the Right Choice for Your Application

Selecting the correct coating requires aligning the technology's strengths with your product's primary goal.

- If your primary focus is maximum durability and wear resistance: PVD is the superior choice, offering a harder, longer-lasting, and more corrosion-resistant finish for high-contact items like tools, watches, or fixtures.

- If your primary focus is cost-effectiveness for decorative purposes: Traditional electroplating remains a viable and economical solution for many applications where extreme durability is not the main concern.

- If your primary focus is environmental standards or a unique color palette: PVD provides a cleaner process and a vastly broader range of aesthetic options that cannot be achieved with plating.

Ultimately, understanding these fundamental differences empowers you to select the coating technology that best aligns with your product's performance, cost, and aesthetic goals.

Summary Table:

| Attribute | PVD Coating | Electroplating |

|---|---|---|

| Process Type | Dry, vacuum-based | Wet, chemical bath |

| Bond Strength | High, molecular-level | Lower, surface adhesion |

| Durability | Extremely hard & wear-resistant | Less durable, may require top coat |

| Color/Material Options | Wide range (metals, ceramics) | Limited to conductive metals |

| Environmental Impact | Low, cleaner process | Higher, uses hazardous chemicals |

| Cost | Higher initial investment | Generally more cost-effective |

Need Help Choosing the Right Coating Technology for Your Lab Equipment?

Understanding the difference between PVD and plating is crucial for selecting the right surface treatment for your laboratory instruments and components. The wrong choice can lead to premature wear, corrosion, or product failure.

KINTEK specializes in providing advanced lab equipment and consumables. Our experts can help you navigate these complex decisions to ensure your products meet the highest standards of performance and durability.

We help you:

- Select the optimal coating for your specific application, whether it's for durability, aesthetics, or chemical resistance.

- Source reliable equipment for your research and development needs.

- Extend the lifespan of your lab tools with the right material science solutions.

Don't leave your product's performance to chance. Contact our specialists today for a personalized consultation and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools