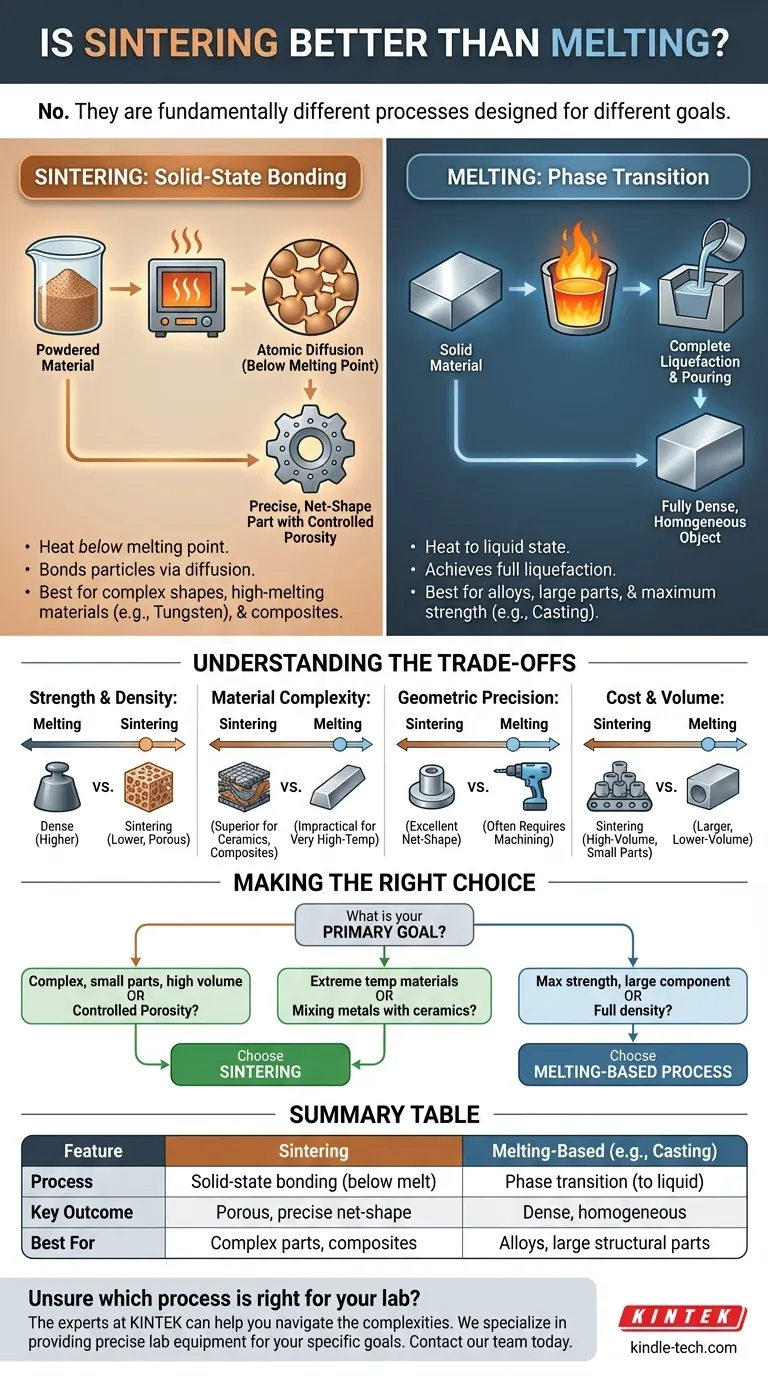

Sintering is not inherently better than melting; they are fundamentally different processes designed to achieve entirely different outcomes. Sintering is a fabrication method that bonds powdered materials into a solid part using heat below the melting point. In contrast, melting is the physical process of turning a solid into a liquid, which is a step used in other manufacturing methods like casting or welding.

The choice between sintering and melting-based processes is not a matter of which is superior, but which is appropriate for your material and final goal. Sintering excels at creating complex net-shape parts from powders, while processes involving melting are used to create fully dense, homogenous objects from a liquid state.

What is Sintering? The Science of Solid-State Bonding

Sintering is a precise thermal treatment for compacting and forming a solid mass of material from a powder. It's a method of fabrication, not just a change of state.

The Goal: Bonding Without Liquefaction

The core principle of sintering is to heat a compressed powder to a temperature where the atoms in the particles become mobile enough to diffuse across the boundaries of adjacent particles. This atomic diffusion creates strong bonds, fusing the separate particles into a coherent, solid piece without ever turning the bulk material into a liquid.

Why Use Powdered Material?

Starting with a powder is the key to sintering's advantages. It allows for the creation of components from materials with extremely high melting points, such as tungsten and molybdenum. It also enables the production of unique composites by mixing metal powders with ceramics, which cannot be combined via melting.

Key Outcome: Precision and Controlled Porosity

Because the material doesn't liquefy, sintered parts hold their shape with high precision. This "net-shape" capability often eliminates the need for expensive secondary machining. The process also leaves behind a network of small pores, which can be a controlled feature for applications like self-lubricating bearings or filters.

What is Melting? The Science of Phase Transition

Melting is a fundamental phase transition where a substance changes from a solid to a liquid. In manufacturing, it is not an end in itself but a critical step within other processes.

The Goal: Complete Liquefaction

The sole purpose of melting is to achieve a fully liquid, homogenous state. This allows materials to be mixed into uniform alloys, purified of impurities, or poured to fill a mold completely.

Applications: Casting, Welding, and Refining

Melting is the foundation for many common manufacturing techniques. In casting, molten metal is poured into a mold to create a solid shape. In welding, localized melting is used to fuse two separate components together. In refining, metals are melted to separate them from slag and other contaminants.

Key Outcome: Full Density and Homogeneity

Processes that use melting, like casting, typically result in a fully dense, non-porous part. The liquid state ensures that the material is uniform throughout, which is critical for applications requiring maximum strength and predictable material properties.

Understanding the Trade-offs

Choosing a path requires understanding the distinct advantages and disadvantages of each approach. The right choice depends entirely on the requirements of your specific component.

Strength and Density

Melting-based processes like casting produce fully dense parts, which are generally stronger and more ductile. The inherent porosity in standard sintered parts can make them more brittle, although post-processing techniques like Hot Isostatic Pressing (HIP) can significantly increase their density and strength.

Material Complexity

Sintering is the superior, and often only, choice for processing materials with exceptionally high melting points (refractory metals and ceramics). It is also the go-to method for creating metal matrix composites (MMCs) where materials with vastly different properties are combined.

Geometric Complexity and Precision

Sintering excels at producing small, highly complex parts in large volumes with exceptional dimensional accuracy right out of the furnace. This minimizes material waste and post-processing costs. While casting can also create complex shapes, achieving the same level of precision often requires more machining.

Cost and Production Volume

For high-volume production of small, intricate components, sintering is extremely cost-effective due to its high degree of automation and net-shape capability. Casting can be more economical for producing larger, simpler parts or for lower production volumes where the cost of creating sintering dies would be prohibitive.

Making the Right Choice for Your Goal

Select your manufacturing process based on the non-negotiable requirements of your project.

- If your primary focus is creating complex, small parts in high volume with minimal waste: Sintering is almost certainly the superior choice due to its net-shape capabilities.

- If your primary focus is maximum strength and a non-porous structure for a large component: A melting-based process like casting or forging will provide better material properties.

- If your primary focus is working with extremely high-temperature materials or mixing metals with ceramics: Sintering is the only viable path, as melting these combinations is often impractical or impossible.

- If your primary focus is creating a part with controlled porosity for filtration or self-lubrication: Sintering is specifically designed to achieve this outcome.

Understanding this fundamental distinction transforms the question from "which is better" to "which is the correct tool for the job."

Summary Table:

| Feature | Sintering | Melting-Based Processes (e.g., Casting) |

|---|---|---|

| Primary Goal | Bond powder particles below melting point | Achieve full liquefaction |

| Best For | Complex net-shape parts, high-melting-point materials | Fully dense, homogeneous parts |

| Typical Outcome | Controlled porosity, high precision | Full density, high strength and ductility |

| Material Flexibility | Excellent for composites and refractory metals | Best for standard alloys |

| Cost Efficiency | High-volume, small, intricate parts | Larger parts, lower volumes |

Unsure which process is right for your lab's materials? The experts at KINTEK can help you navigate the complexities of sintering and melting-based fabrication. We specialize in providing the precise lab equipment and consumables you need to achieve your specific goals, whether you're working with high-temperature ceramics or complex metal alloys. Contact our team today to discuss your project and discover the ideal solution for your laboratory's unique challenges.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What is the sintering time for zirconia crowns? Master the Trade-Off Between Speed and Strength

- What does a dental furnace do? Achieve Perfect, Lifelike Dental Restorations

- What is the mode of failure most often associated with ceramic dental implants? Understanding Fracture Risk

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle