Yes, several things can survive a hydraulic press, but it's a matter of physics, not magic. Survival depends entirely on whether an object's properties can withstand or redirect the immense pressure the press applies. It's not about being "unbreakable" but about winning a contest of competing forces.

The question isn't whether an object is indestructible, but whether its compressive strength is greater than the pressure the specific hydraulic press can exert. Survival is a battle of material science against mechanical force.

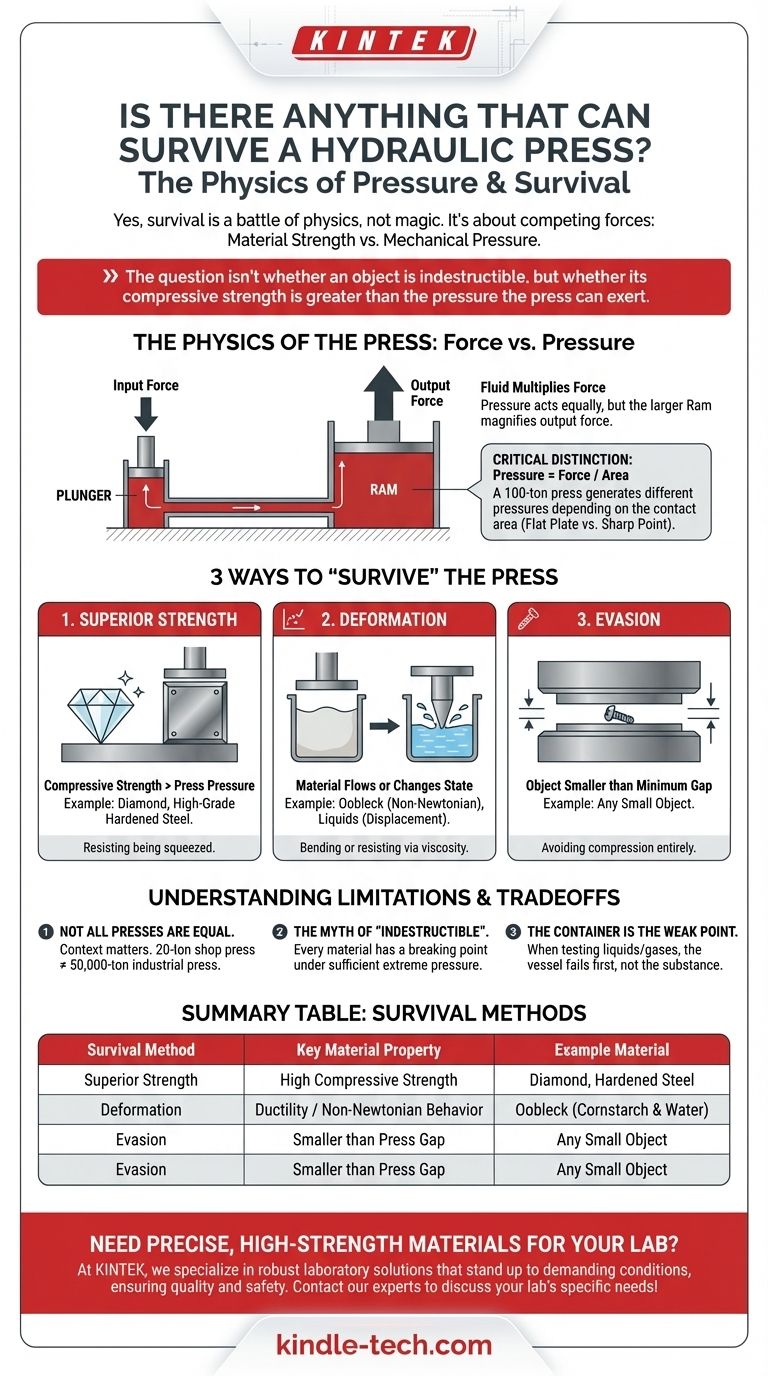

The Physics of the Press: Force vs. Pressure

A hydraulic press creates an advantage by using an incompressible fluid, like oil, to multiply force. This is the core principle that allows it to crush seemingly solid objects.

How It Generates Force

A press consists of two connected cylinders of different sizes: a small Plunger and a large Ram. A small force applied to the plunger creates pressure in the fluid. This pressure acts equally across the entire system, but because the Ram has a much larger surface area, the resulting output force is magnified enormously.

The Critical Distinction: Force and Pressure

The power of a press is often measured in tons of force. While impressive, this number alone is misleading.

The truly important metric is pressure, which is defined as force distributed over an area (Pressure = Force / Area). A 100-ton press applying its force over a large, flat plate generates less pressure than the same press applying that force through a single, sharp point.

What 'Survival' Really Means

An object can "survive" a press in a few distinct ways. It's not always about rigid defiance; sometimes, it's about clever properties or exploiting loopholes.

Method 1: Surviving Through Superior Strength

This is the most direct form of survival. If an object's compressive strength—its ability to resist being squeezed—is higher than the pressure the press can generate, it will not be crushed.

A perfect example is a diamond. As one of the hardest known materials, a small diamond could easily withstand the pressure of a standard workshop press, which might only reach a fraction of the pressure needed to deform its crystal lattice. Similarly, a block of high-grade hardened steel, perhaps even a piston from a more powerful press, could survive.

Method 2: Surviving Through Deformation

Some materials don't break under pressure; they flow. A non-Newtonian fluid, like a mixture of cornstarch and water (oobleck), is a fascinating example. When pressure is applied slowly, it behaves like a liquid. When immense force is applied suddenly, its viscosity increases dramatically, and it becomes temporarily rigid, resisting the force.

Liquids and gases are also technically "survivors." You cannot crush water; you can only displace it or increase its pressure. The press would simply force the water out from the sides. If the water is perfectly contained, the container becomes the point of failure, not the water itself.

Method 3: Surviving Through Evasion

This is a literal but valid answer. An object that is smaller than the minimum gap between the press's plates when fully closed will, by definition, survive. It never comes under compression in the first place.

Understanding the Limitations and Trade-offs

The phrase "hydraulic press" is not a monolith. Context is everything, and the idea of absolute indestructibility is a myth.

Not All Presses Are Equal

A 20-ton shop press is a world away from a 50,000-ton industrial forging press used to shape aircraft components. An object that survives the former would be obliterated by the latter. The question "Can it survive a press?" is meaningless without knowing the press's maximum force and the area over which it's applied.

The Myth of 'Indestructible'

Every material has a breaking point. A diamond will survive a common press, but it can be crushed by specialized laboratory equipment designed to generate extreme pressures. There is no known material that can withstand infinite pressure.

The Container Is the Weak Point

When testing liquids, gases, or powders, the object of failure is almost always the container. The press will find the weakest link, which will be the vessel holding the material, not the material itself.

Key Factors Determining Survival

To predict the outcome, you must compare the press's capability with the object's properties.

- If your primary focus is resisting crushing: You need a solid material whose compressive strength (measured in PSI or Pascals) is greater than the pressure the press can exert.

- If your primary focus is avoiding shattering: You should consider ductile materials that bend or non-Newtonian fluids that deform and resist without breaking apart.

- If your primary focus is theoretical survival: A perfectly sealed container of a liquid or gas will survive, but only because the container itself will fail first.

Ultimately, predicting survival is a straightforward calculation of whether the material's resistance is greater than the force applied to it.

Summary Table:

| Survival Method | Key Material Property | Example Material |

|---|---|---|

| Superior Strength | High Compressive Strength | Diamond, Hardened Steel |

| Deformation | Ductility / Non-Newtonian Behavior | Oobleck (Cornstarch & Water) |

| Evasion | Smaller than Press Gap | Any Small Object |

Need precise, high-strength materials for your lab applications? The principles of material survival under pressure are critical for reliable lab equipment and consumables. At KINTEK, we specialize in providing robust laboratory solutions that stand up to demanding conditions. Whether you require durable equipment components or specialized materials, our expertise ensures your lab operates with uncompromising quality and safety. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy