The short answer is that neither is universally "better." The ideal choice between thermal evaporation and magnetron sputtering depends entirely on your specific goals for film quality, deposition speed, material type, and budget. Sputtering generally produces higher-quality, more adherent films with greater material versatility, while thermal evaporation is simpler, faster, and more cost-effective for many applications.

The decision is a fundamental trade-off between film quality and process efficiency. Magnetron sputtering offers superior control and film integrity at the cost of speed and complexity. Thermal evaporation offers unmatched speed and simplicity, making it ideal for applications where absolute film perfection is not the primary driver.

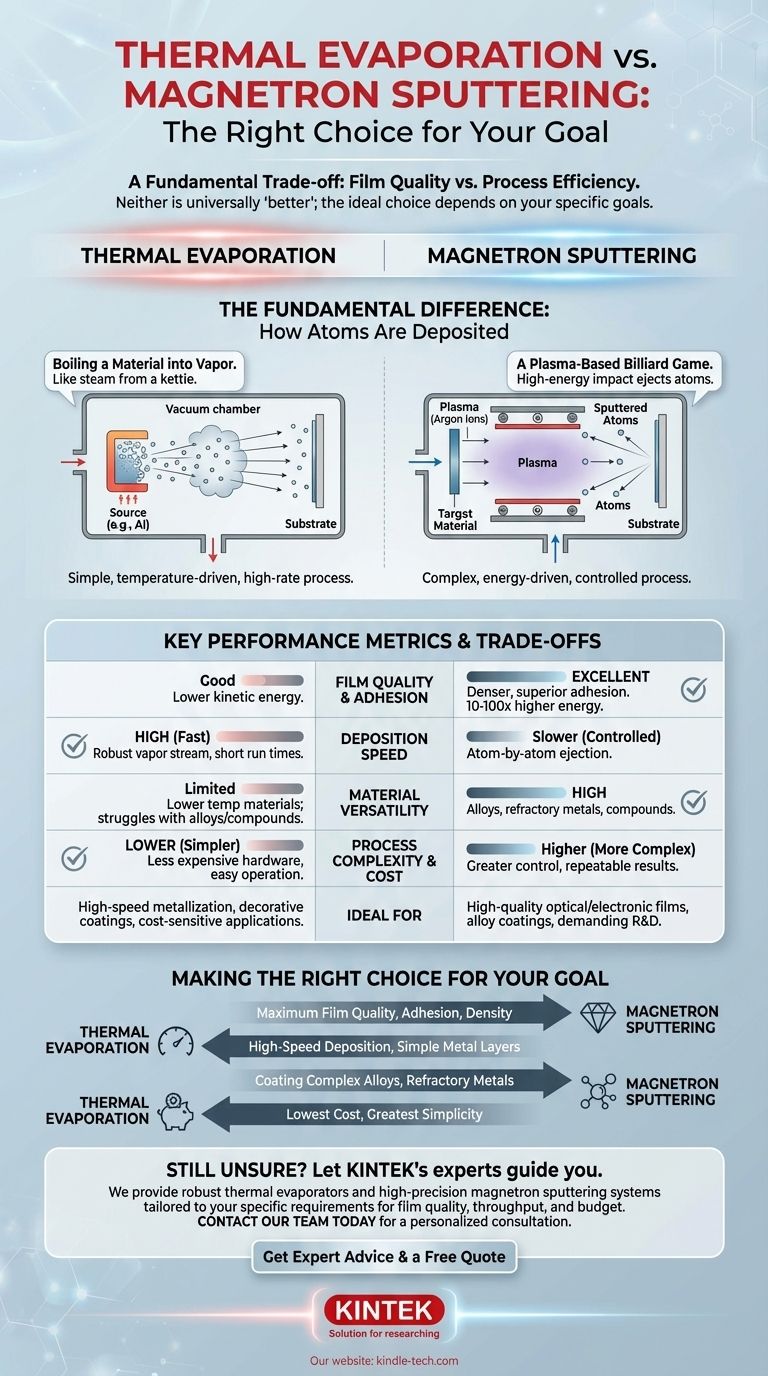

The Fundamental Difference: How Atoms Are Deposited

Understanding how each method works is the key to choosing the right one. The two processes move material from a source to your substrate in fundamentally different ways.

Thermal Evaporation: Boiling a Material into Vapor

Thermal evaporation is an intuitive process. In a high vacuum, a source material (like aluminum) is heated until it begins to boil and evaporate, creating a cloud of vapor. This vapor travels in a straight line until it condenses on the cooler substrate, forming a thin film.

Think of it like steam from a boiling kettle condensing on a cold window pane. It's a relatively simple, high-rate process driven by temperature.

Magnetron Sputtering: A Plasma-Based Billiard Game

Sputtering is a more complex, energetic process. It begins by creating a plasma (an ionized gas, usually argon) within the vacuum chamber. A strong electric and magnetic field then accelerates these gas ions, slamming them into the source material, known as the "target."

This high-energy impact is like a subatomic game of pool. The ions act as the cue ball, knocking atoms loose from the target material. These ejected ("sputtered") atoms then travel and deposit onto the substrate.

Comparing Key Performance Metrics

Your application's priorities will determine which of these metrics is most important.

Film Quality and Adhesion

Sputtering is the clear winner here. Sputtered atoms have significantly higher kinetic energy (10-100x more) than evaporated atoms. This energy helps them form a denser, more uniform film with far superior adhesion to the substrate.

Deposition Rate and Speed

Thermal evaporation is generally much faster. It produces what the references call a "robust vapor stream," allowing for very high deposition rates and short run times. This makes it excellent for coating large areas or creating thicker films quickly.

Sputtering, by contrast, ejects atoms one by one, resulting in a slower, more controlled deposition rate.

Material Versatility

Sputtering offers broader material capability. Because it is a physical, momentum-transfer process, sputtering can deposit almost any material, including high-melting-point metals (like tungsten), alloys, and even compounds.

Thermal evaporation is limited to materials that can be evaporated without decomposing. It struggles with very high-temperature materials and can cause elements in an alloy to evaporate at different rates, changing the film's composition.

Step Coverage and Uniformity

This is a nuanced comparison. Because sputtering is a more scattered process, it generally provides better step coverage, meaning it can coat the sides of microscopic features more conformally.

Evaporation is a "line-of-sight" process, which can create shadows behind features. However, with proper tooling like planetary rotation, it can achieve excellent film thickness uniformity over large, flat substrates.

Understanding the Trade-offs: Cost vs. Control

The decision often comes down to balancing your budget and the level of precision you require.

System Cost and Simplicity

Thermal evaporation systems are significantly simpler and less expensive. The hardware is more straightforward, requires less power, and is generally easier to operate and maintain. This makes it an accessible entry point for thin-film deposition.

Process Control and Repeatability

Sputtering offers unparalleled control. By adjusting parameters like gas pressure, power, and target material, you can precisely tune film properties like internal stress, density, and composition. This level of control leads to highly repeatable results for demanding applications like semiconductor manufacturing or precision optics.

Color and Decorative Finishes

Sputtering's ability to deposit compounds and alloys gives it a much wider color palette. For example, reactive sputtering with nitrogen and titanium creates titanium nitride (TiN), a hard, gold-colored coating. Thermal evaporation is typically limited to the intrinsic color of the source material.

Making the Right Choice for Your Goal

Use these guidelines to determine the best method for your project.

- If your primary focus is maximum film quality, adhesion, and density: Choose magnetron sputtering. It is the standard for demanding optical, electronic, and wear-resistant applications.

- If your primary focus is high-speed deposition or simple metal layers: Choose thermal evaporation. It is perfect for rapid metallization, decorative coatings, and applications where cost and throughput are critical.

- If your primary focus is coating complex alloys or refractory metals: Choose magnetron sputtering. Its physical ejection mechanism can handle virtually any material without altering its composition.

- If your primary focus is the lowest cost and greatest simplicity: Choose thermal evaporation. It is the most economical and straightforward method for many basic thin-film applications.

Ultimately, the best deposition method is the one that reliably and cost-effectively meets the technical requirements of your specific goal.

Summary Table:

| Feature | Thermal Evaporation | Magnetron Sputtering |

|---|---|---|

| Film Quality & Adhesion | Good | Excellent (Denser, Superior Adhesion) |

| Deposition Speed | High (Fast) | Slower (Controlled) |

| Material Versatility | Limited (Lower temp. materials) | High (Alloys, Refractory Metals) |

| Process Complexity & Cost | Lower (Simpler, More Cost-Effective) | Higher (More Complex, Greater Control) |

| Ideal For | High-speed metallization, Decorative coatings, Cost-sensitive applications | High-quality optical/electronic films, Alloy coatings, Demanding R&D |

Still Unsure Which Deposition Method is Right for Your Project?

Let KINTEK's experts guide you to the optimal solution. We specialize in providing the right lab equipment—from robust thermal evaporators to high-precision magnetron sputtering systems—to meet your specific requirements for film quality, throughput, and budget.

Contact our team today for a personalized consultation and discover how we can enhance your laboratory's capabilities.

Get Expert Advice & a Free Quote

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition