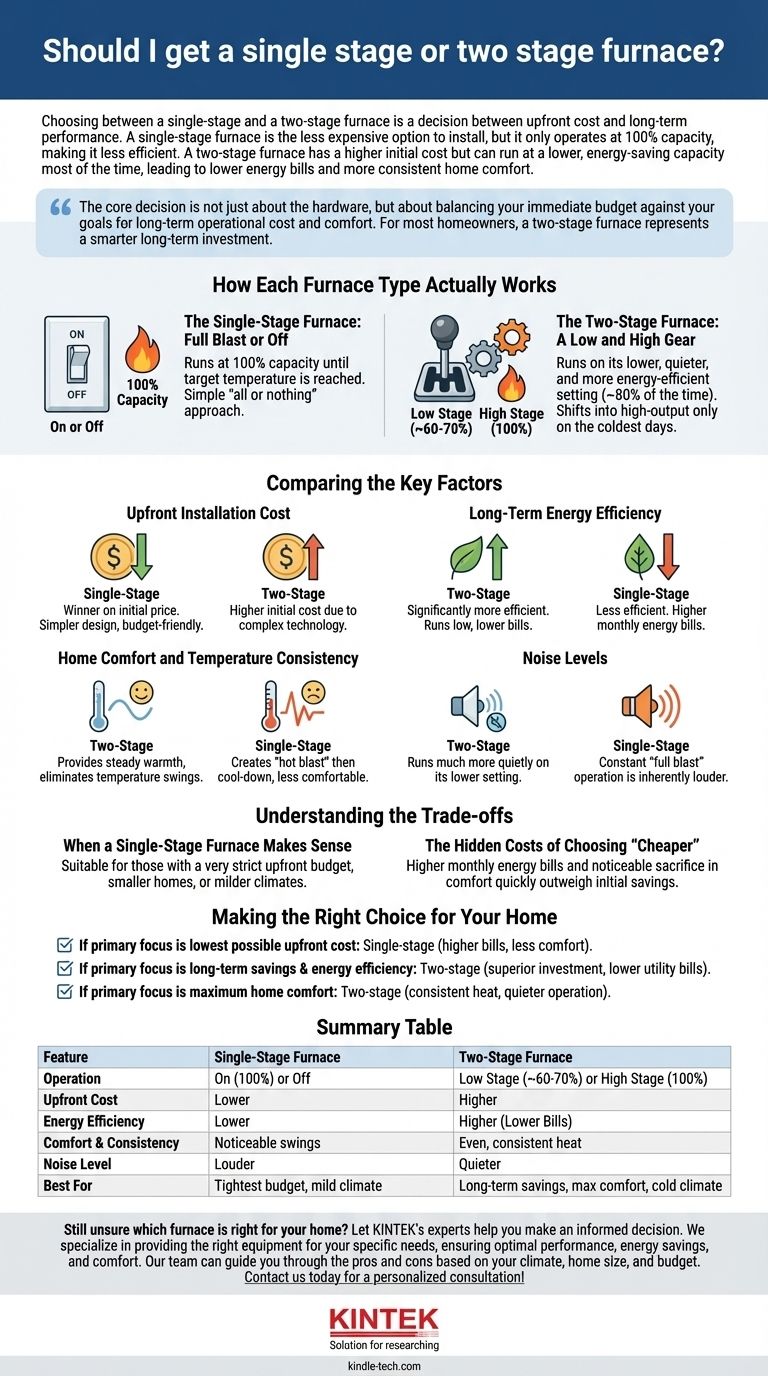

Choosing between a single-stage and a two-stage furnace is a decision between upfront cost and long-term performance. A single-stage furnace is the less expensive option to install, but it only operates at 100% capacity, making it less efficient. A two-stage furnace has a higher initial cost but can run at a lower, energy-saving capacity most of the time, leading to lower energy bills and more consistent home comfort.

The core decision is not just about the hardware, but about balancing your immediate budget against your goals for long-term operational cost and comfort. For most homeowners, a two-stage furnace represents a smarter long-term investment.

How Each Furnace Type Actually Works

To make an informed choice, you first need to understand the fundamental difference in how these two systems operate. They approach the task of heating your home in vastly different ways.

The Single-Stage Furnace: Full Blast or Off

Think of a single-stage furnace like a simple light switch: it's either completely on or completely off.

When your thermostat calls for heat, the furnace fires up and runs at 100% of its capacity until the target temperature is reached. It then shuts off completely. This "all or nothing" approach is simple and makes the furnace cheaper to manufacture.

The Two-Stage Furnace: A Low and High Gear

A two-stage furnace is more sophisticated, operating like a car with two gears. It has a low-output stage and a high-output stage.

Most of the time (around 80%), it will run on its lower, quieter, and more energy-efficient setting (typically around 60-70% of its total capacity). This allows it to run for longer, gentler cycles. It only shifts into the high-output stage on the coldest days when it needs the extra power to heat your home effectively.

Comparing the Key Factors

The operational differences between these systems create clear trade-offs in cost, efficiency, and the overall feel of your home.

Upfront Installation Cost

A single-stage furnace is the clear winner on initial price. Its simpler design and components make it the most budget-friendly option for installation.

A two-stage furnace will cost more upfront due to its more complex technology, including the two-stage gas valve and variable-speed blowers.

Long-Term Energy Efficiency

The two-stage furnace is significantly more efficient. By running primarily on its low setting, it avoids the energy-intensive process of constantly firing up at full power and then shutting down.

This efficiency translates directly into lower monthly energy bills, which can offset the higher initial purchase price over the furnace's lifespan.

Home Comfort and Temperature Consistency

This is where the two-stage furnace truly excels. Its long, low-running cycles provide a steady stream of warmth that eliminates the noticeable temperature swings common with single-stage units.

Single-stage furnaces often create a "hot blast" of air, followed by a cool-down period, which can feel less comfortable. The two-stage model provides a much more even and consistent indoor climate.

Noise Levels

The constant "full blast" operation of a single-stage furnace is inherently louder. A two-stage furnace runs much more quietly on its lower setting, which is how it operates most of the time, leading to a quieter home environment.

Understanding the Trade-offs

Neither option is universally "bad," but choosing the wrong one for your situation can lead to regret.

When a Single-Stage Furnace Makes Sense

Despite its downsides, a single-stage unit can be a practical choice in specific scenarios. It is often suitable for those with a very strict upfront budget, for smaller homes that heat up quickly, or for properties in milder climates where the furnace is used less frequently.

The Hidden Costs of Choosing "Cheaper"

For most people, especially those in climates with cold winters, the lower sticker price of a single-stage furnace can be misleading.

The higher monthly energy bills and the noticeable sacrifice in comfort are long-term costs that can quickly outweigh the initial savings.

Making the Right Choice for Your Home

Your decision should be guided by your primary goal for this long-term investment.

- If your primary focus is the lowest possible upfront cost: A single-stage furnace is the most budget-friendly choice for installation, but be prepared for higher energy bills and less consistent comfort.

- If your primary focus is long-term savings and energy efficiency: A two-stage furnace is the superior investment, as its efficiency will typically pay for the higher initial cost over time through lower utility bills.

- If your primary focus is maximum home comfort: The two-stage furnace provides far more consistent heat and quieter operation, eliminating the temperature swings common with single-stage models.

By understanding how these systems operate, you can confidently choose the furnace that aligns with both your budget and your long-term comfort goals.

Summary Table:

| Feature | Single-Stage Furnace | Two-Stage Furnace |

|---|---|---|

| Operation | On (100%) or Off | Low Stage (~60-70%) or High Stage (100%) |

| Upfront Cost | Lower | Higher |

| Energy Efficiency | Lower | Higher (Lower Bills) |

| Comfort & Consistency | Noticeable temperature swings | Even, consistent heat |

| Noise Level | Louder | Quieter |

| Best For | Tightest upfront budget, milder climates | Long-term savings, maximum comfort, colder climates |

Still unsure which furnace is right for your home?

Let KINTEK's experts help you make an informed decision. We specialize in providing the right equipment for your specific needs, ensuring optimal performance, energy savings, and comfort. Our team can guide you through the pros and cons based on your climate, home size, and budget.

Contact us today for a personalized consultation!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Multi-zone Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas