To be precise, pellet dies used for X-ray fluorescence (XRF) sample preparation are primarily manufactured from hardened 440C stainless steel. For specialized applications where elemental contamination is a concern, alternatives such as Tungsten Carbide are used for the critical pressing surfaces. All high-quality dies feature a mirror finish on these faces to ensure sample consistency.

The choice of a pellet die's material is not just about strength; it is a critical decision to prevent elemental contamination of the sample, which directly impacts the accuracy of your analytical results.

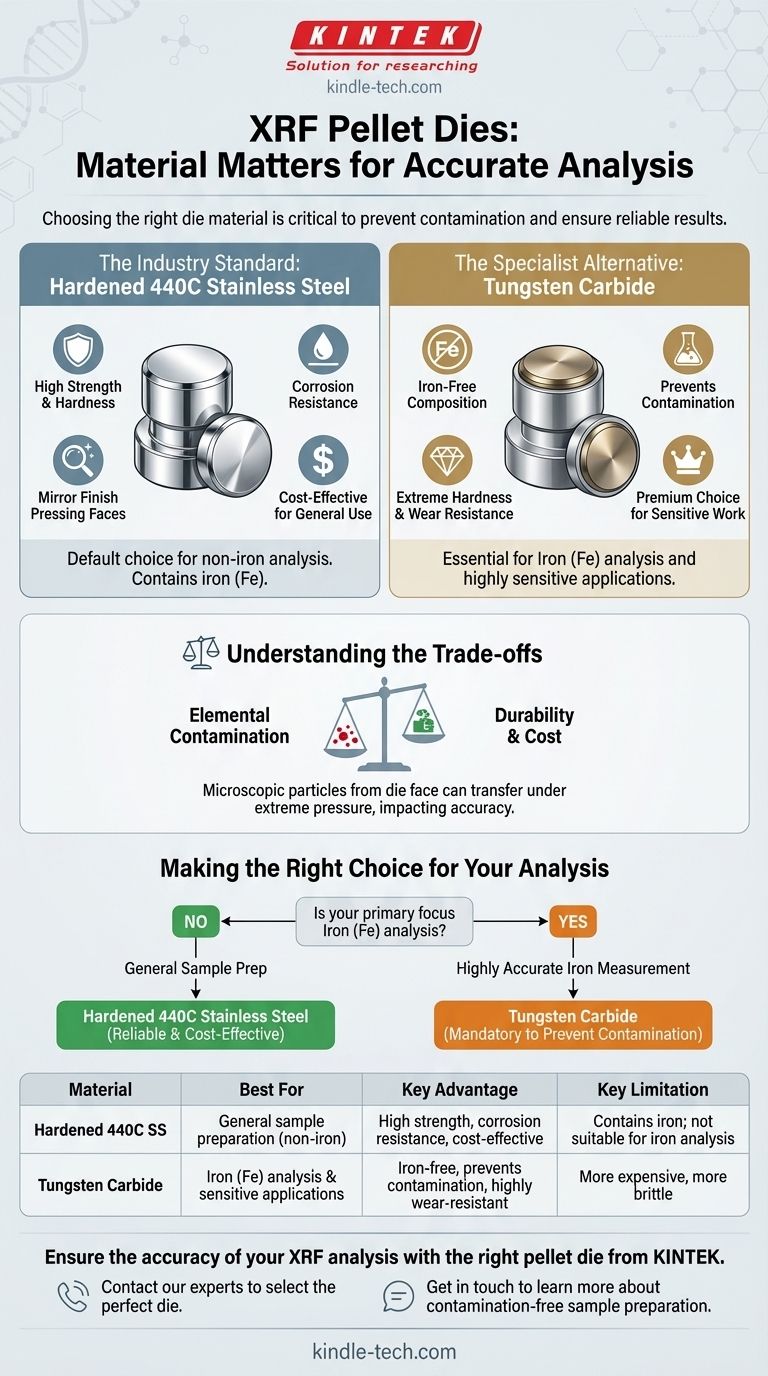

The Industry Standard: Hardened 440C Stainless Steel

The vast majority of laboratory pellet dies rely on a specific type of steel for its unique combination of properties, making it the default choice for a wide range of applications.

Why 440C Steel is the Default Choice

Hardened 440C stainless steel provides an exceptional balance of high strength, hardness, and corrosion resistance. This durability is essential to withstand the immense pressures required to create a solid, homogenous sample pellet without the die deforming or breaking.

The Critical Role of the Pressing Face

The most important parts of the die are the internal pressing faces—the surfaces that come into direct contact with your sample. These faces are precision-machined from 440C steel to be perfectly flat and smooth.

How a Mirror Finish Ensures Repeatability

These pressing faces are polished to a mirror finish. This ultra-smooth surface prevents sample material from sticking, ensures uniform density across the pellet, and makes cleaning between samples easier, which is crucial for preventing cross-contamination and achieving repeatable results.

The Specialist Alternative: Tungsten Carbide

While 440C steel is an excellent general-purpose material, it has one significant limitation that necessitates an alternative for certain types of sensitive analysis.

When to Avoid Stainless Steel

The primary reason to use an alternative material is to avoid sample contamination. Because 440C is a stainless steel, it contains iron (Fe). If you are pressing a sample where iron is a specific element of interest, the steel die itself can introduce trace amounts of iron into the pellet, compromising your analysis.

Why Tungsten Carbide is the Solution

For these iron-sensitive studies, dies with Tungsten Carbide pressing faces are used. Tungsten Carbide is an extremely hard ceramic composite material that is free of iron. This makes it the ideal choice for ensuring that any iron detected in your XRF analysis comes from the sample itself, not from the preparation equipment.

Understanding the Trade-offs

Choosing the right die material involves balancing analytical needs with practical considerations. The wrong choice can invalidate your results before you even begin the analysis.

The Primary Concern: Elemental Contamination

Under extreme pressure, microscopic particles from the die face can be transferred to the sample. This is the single most important factor in material selection. Using a steel die for iron analysis is a classic example of introducing analytical interference.

Durability and Cost

While both materials are highly durable, Tungsten Carbide is harder and more wear-resistant than even hardened steel. However, it is also more brittle and significantly more expensive. For most labs, the excellent performance and lower cost of 440C steel make it the practical choice for all non-iron-related work.

Making the Right Choice for Your Analysis

Your analytical goal should be the sole determining factor in your equipment choice.

- If your primary focus is general sample preparation and your analysis does not involve iron (Fe): A standard die made from hardened 440C stainless steel is the reliable and cost-effective choice.

- If your primary focus is the highly accurate measurement of iron (Fe): A die with Tungsten Carbide pressing faces is mandatory to prevent sample contamination and ensure valid results.

Ultimately, selecting the correct die material is a foundational step in achieving accurate and defensible analytical outcomes.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Hardened 440C Stainless Steel | General sample preparation (non-iron analysis) | High strength, corrosion resistance, cost-effective | Contains iron; not suitable for iron analysis |

| Tungsten Carbide | Iron (Fe) analysis and sensitive applications | Iron-free, prevents contamination, highly wear-resistant | More expensive, more brittle |

Ensure the accuracy of your XRF analysis with the right pellet die.

Choosing the correct die material is critical for preventing elemental contamination and achieving reliable results. At KINTEK, we specialize in high-quality lab equipment and consumables, including precision pellet dies made from hardened 440C stainless steel and Tungsten Carbide, tailored to your specific analytical needs.

Contact us today to discuss your application and let our experts help you select the perfect die for your laboratory. Get in touch via our contact form to learn more about our products and how we can support your research with dependable, contamination-free sample preparation.

Visual Guide

Related Products

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Ring Press Mold for Lab Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the role of graphite molds in SPS of UHTCMCs? Enhancing Precision and Material Toughness

- What are the specific functions of a nylon die during battery mold assembly? Ensure Accurate Solid-State Battery Testing

- What is the function of a stainless steel battery cell mold? Precision Pressure for LiFePO4 Research

- What is the application of three plate mould? Achieve Balanced Flow for Complex Parts

- What are the key functions of a graphite mold during the SPS of LATP materials? Unlock Precise Material Densification

- What is the function of graphite molds in vacuum hot pressing? Optimize Lithium Niobate Sintering

- What is cold isostatic pressing mold material? Essential Elastomers for Uniform Density

- What role do specialized pressure dies play in Cold Sintering multi-layer batteries? Ensure Flawless Device Integration