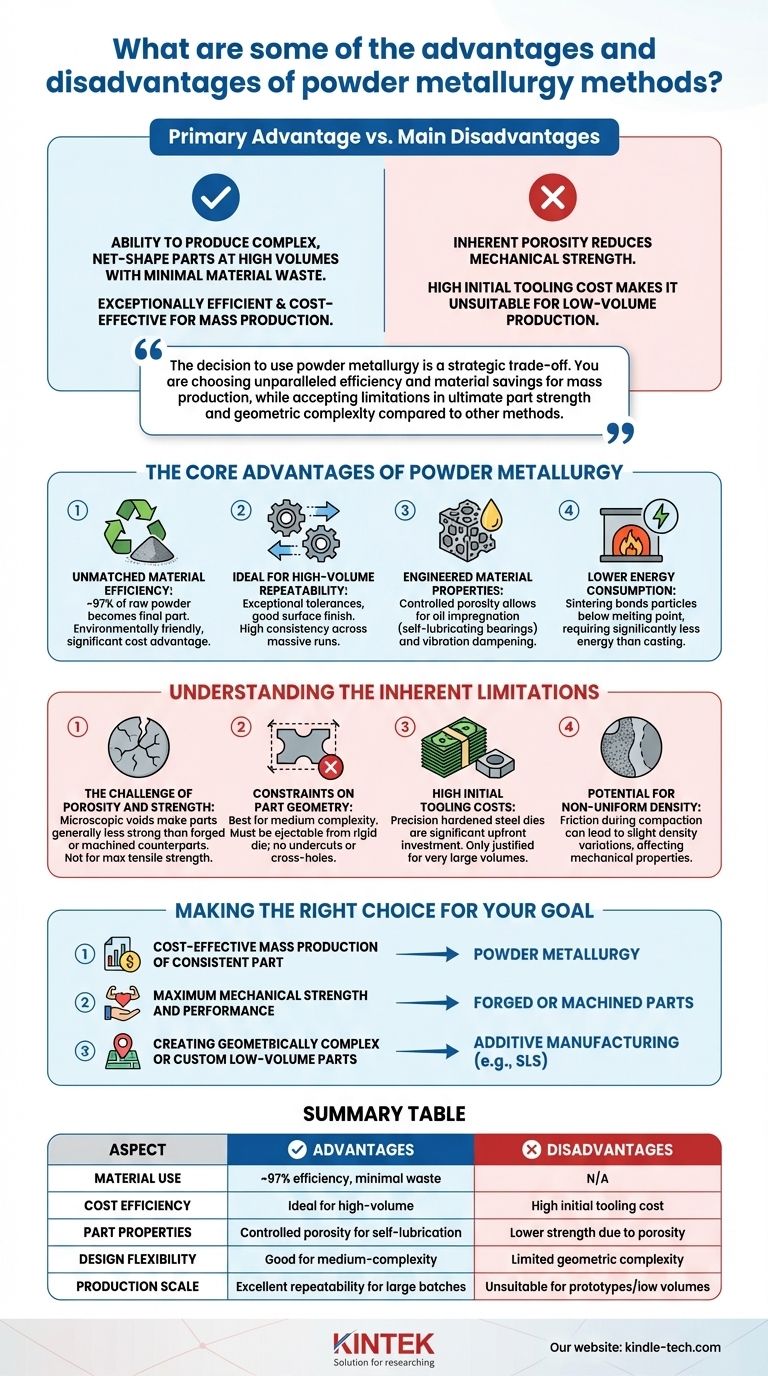

The primary advantage of powder metallurgy is its ability to produce complex, net-shape parts at high volumes with minimal material waste. This makes it an exceptionally efficient and cost-effective manufacturing process. However, its main disadvantages are the inherent porosity of the final parts, which can reduce mechanical strength, and the high initial cost of tooling, which makes it unsuitable for low-volume production.

The decision to use powder metallurgy is a strategic trade-off. You are choosing unparalleled efficiency and material savings for mass production, while accepting limitations in ultimate part strength and geometric complexity compared to other methods.

The Core Advantages of Powder metallurgy

Powder metallurgy (PM) has become a vital manufacturing process because it offers a unique combination of benefits that are difficult to achieve with traditional methods like machining or forging.

Unmatched Material Efficiency

The standout benefit of PM is its incredibly low level of waste. Approximately 97% of the raw powder entering the process becomes part of the final component.

This near-elimination of scrap makes it an environmentally friendly or "green" technology and provides a significant cost advantage, especially when using expensive materials.

Ideal for High-Volume Repeatability

PM excels at producing large quantities of identical parts with exceptional tolerances and a good surface finish.

Because parts are formed in a die, the process delivers high repeatability across massive production runs, ensuring consistency from the first part to the last. This is crucial for industries like automotive and aerospace.

Engineered Material Properties

Unlike in other processes where it is purely a defect, the controlled porosity in PM parts can be a design advantage.

This porosity allows for oil impregnation, creating self-lubricating bearings that require little to no maintenance. It also gives PM parts excellent vibration-dampening characteristics.

Lower Energy Consumption

The core of the process is sintering, where metal particles are bonded under heat well below the material's melting point.

This requires significantly less energy than melting metal for casting, further contributing to its cost-effectiveness and environmental credentials.

Understanding the Inherent Limitations

While powerful, PM is not a universal solution. Its limitations are directly tied to the nature of the process itself.

The Challenge of Porosity and Strength

The same porosity that can be a benefit is also the primary source of weakness. The microscopic voids within the material mean that PM parts are generally less strong than their fully dense counterparts made by forging or machining.

For applications requiring maximum tensile strength or fatigue resistance, traditional methods are often superior.

Constraints on Part Geometry

Powder metallurgy is best suited for parts of medium complexity. The raw powder must be pressed in a rigid die, and the compacted "green" part must be ejected.

This fundamental requirement restricts features like undercuts, cross-holes, or threads that would prevent the part from being removed from the tooling. More advanced methods like additive manufacturing offer far greater design freedom.

High Initial Tooling Costs

The dies and molds used for compacting the powder must be made with extreme precision from hardened steel.

This tooling represents a significant upfront investment. The high cost can only be justified when spread across a very large production volume, making PM entirely unsuitable for prototypes or small runs.

Potential for Non-Uniform Density

During the compaction stage, friction between the metal powder and the die walls can hinder uniform pressure distribution. This can lead to slight variations in density throughout the part, which may affect its mechanical properties.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process requires aligning its capabilities with your project's specific priorities.

- If your primary focus is cost-effective mass production of a consistent part: Powder metallurgy is an outstanding choice due to its high material utilization and exceptional repeatability.

- If your primary focus is maximum mechanical strength and performance: Forged or machined parts created from solid metal billets are generally the superior option.

- If your primary focus is creating geometrically complex or custom low-volume parts: Additive manufacturing methods like Selective Laser Sintering (SLS) are a much better fit, despite their higher per-part cost.

By understanding these core trade-offs, you can confidently determine if powder metallurgy is the optimal path for your manufacturing needs.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Material Use | ~97% material efficiency, minimal waste | N/A |

| Cost Efficiency | Ideal for high-volume production | High initial tooling cost |

| Part Properties | Controlled porosity for self-lubrication | Lower mechanical strength due to porosity |

| Design Flexibility | Good for medium-complexity, net-shape parts | Limited geometric complexity (no undercuts) |

| Production Scale | Excellent repeatability for large batches | Unsuitable for prototypes or low volumes |

Need high-quality, cost-effective parts for your large-scale production? KINTEK specializes in precision lab equipment and consumables, offering tailored solutions that leverage efficient manufacturing processes like powder metallurgy. Whether you require durable components or specialized tooling, our expertise ensures optimal performance and material savings for your laboratory needs. Contact us today to discuss how we can support your project with reliable, high-volume manufacturing solutions!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- What is cold isostatic pressing mold material? Essential Elastomers for Uniform Density

- What is a cold isostatic press? Achieve Uniform Powder Compaction for Complex Parts

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing