At its core, brazing offers the ability to create strong, clean joints between dissimilar materials without melting the base metals. This process uses a filler metal that melts at a lower temperature and is drawn into the joint by capillary action, forming a solid metallurgical bond upon cooling. While powerful, its effectiveness is highly dependent on precise process control.

The central trade-off of brazing is one of control versus cost. While simple torch brazing is accessible, it risks damaging the workpiece. Conversely, highly controlled furnace brazing produces superior, repeatable joints but requires significant investment in equipment and process development.

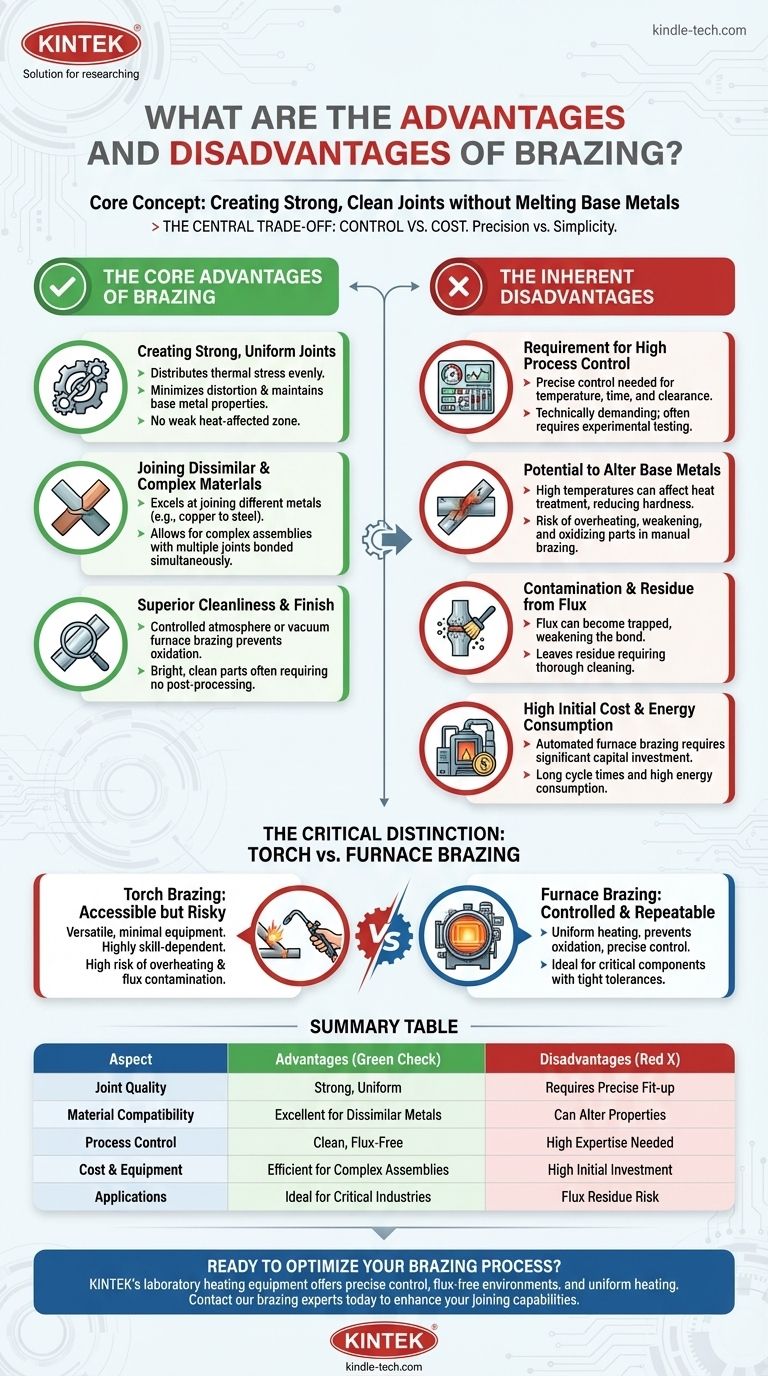

The Core Advantages of Brazing

Brazing is selected over other joining methods for several distinct benefits, particularly in applications requiring high precision and material integrity.

Creating Strong, Uniform Joints

Brazing distributes thermal stress more evenly across the joint compared to welding. This minimizes distortion and maintains the mechanical properties of the parent materials.

Because the base metals are not melted, there is less risk of altering their fundamental structure or creating a weak heat-affected zone.

Joining Dissimilar and Complex Materials

This process excels at joining different types of metals, such as copper to steel, which can be difficult or impossible to weld.

The use of a filler metal allows for the creation of complex assemblies with multiple joints, which can all be bonded simultaneously in a single furnace cycle, increasing efficiency.

Superior Cleanliness and Finish

Controlled atmosphere or vacuum furnace brazing is an exceptionally clean process. It actively prevents and even removes oxides from the part surfaces.

This results in bright, clean parts with high-quality joints that often require no post-processing or cleaning, a significant advantage for industries like medical, aerospace, and semiconductor.

Understanding the Inherent Disadvantages

The benefits of brazing are balanced by several challenges and limitations that must be carefully managed.

Requirement for High Process Control

Brazing success is dictated by precise control over parameters like temperature, time, heating and cooling rates, and joint clearance.

Determining the optimal combination of these parameters often requires experimental testing, making the process technically demanding.

Potential to Alter Base Metals

While brazing temperatures are lower than welding, they are still high enough to affect the heat treatment of the base metals. This can result in reduced hardness or other changes in material properties.

In manual torch brazing, it is easy to overheat the part, which can weaken and oxidize the base metal, resulting in a weak and unsightly joint.

Contamination and Residue from Flux

Many brazing processes, especially open-air torch brazing, require a chemical flux to prevent oxidation and clean the metal surfaces.

This flux can become trapped within the joint, creating voids that weaken the bond. It also leaves behind a residue that must be thoroughly cleaned after the operation.

High Initial Cost and Energy Consumption

Automated furnace brazing, particularly vacuum brazing, requires a significant capital investment in equipment.

The processes can also have long cycle times and high energy consumption, contributing to higher operational costs compared to simpler joining methods.

The Critical Distinction: Torch vs. Furnace Brazing

The advantages and disadvantages you experience are heavily influenced by the specific brazing method you employ.

Torch Brazing: Accessible but Risky

Hand brazing with a torch is versatile and requires minimal equipment. It is often used for repairs and low-volume production.

However, it relies entirely on operator skill. The risk of overheating, uneven heat application, and flux contamination is very high.

Furnace Brazing: Controlled and Repeatable

Brazing inside a vacuum or controlled atmosphere furnace provides uniform heating, prevents oxidation without flux, and allows for precise, repeatable control over the entire cycle.

This method produces the highest quality joints and is ideal for critical components with tight tolerances, though it involves a much higher initial investment.

Making the Right Choice for Your Application

Selecting the correct approach depends entirely on your project's specific requirements for quality, volume, and cost.

- If your primary focus is high-volume production of critical components: Furnace brazing is the definitive choice for its exceptional repeatability, cleanliness, and joint integrity.

- If your primary focus is joining complex assemblies or dissimilar metals: Brazing is an excellent candidate, but the required joint strength will determine if a controlled furnace process is necessary.

- If your primary focus is low-cost repairs or one-off prototypes: Manual torch brazing can be effective, provided you carefully manage heat input and flux application to avoid damaging the parts.

Understanding these trade-offs allows you to leverage brazing not just as a joining process, but as a precise engineering tool.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Joint Quality | Strong, uniform joints with minimal distortion | Requires precise joint clearance and fit-up |

| Material Compatibility | Excellent for joining dissimilar metals | Can alter base metal heat treatment properties |

| Process Control | Clean, flux-free joints in controlled atmospheres | High technical expertise and parameter control needed |

| Cost & Equipment | Efficient for complex multi-joint assemblies | High initial investment for furnace brazing systems |

| Applications | Ideal for medical, aerospace, and semiconductor industries | Flux residue risk in torch brazing requires post-cleaning |

Ready to Optimize Your Brazing Process?

Whether you're joining dissimilar metals for aerospace components or creating complex assemblies for medical devices, KINTEK's expertise in laboratory heating equipment can transform your brazing results. Our controlled atmosphere and vacuum furnaces deliver the precision, repeatability, and cleanliness your critical applications demand.

We help you overcome brazing challenges by providing:

- Precise Temperature Control for consistent, high-quality joints

- Flux-Free Environments that eliminate contamination risks

- Uniform Heating Solutions to minimize distortion and stress

- Technical Support from brazing specialists who understand material science

Don't let process limitations compromise your product integrity. Contact our brazing experts today to discuss how KINTEK's laboratory equipment solutions can enhance your joining capabilities and deliver superior results for your specific application needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Non Consumable Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

People Also Ask

- What is the inside of a kiln made of? Discover the Refractory Materials That Withstand Extreme Heat

- What is vacuum furnace brazing? Achieve Superior Metal Joining with Unmatched Purity

- How does a condensation column with a temperature gradient function? Master High-Purity Metal Distillation

- How do you lower sintering temperature? Achieve Dense Materials at Lower Costs

- Why is precise temperature control necessary in alloy testing in molten chloride salts? Achieve Valid Research Results

- What role do high-temperature furnaces play in sintering ceramic membranes? Optimize Your Filter Production

- Can brazing be used to join dissimilar metals? Achieve Strong, Reliable Bonds Without Melting

- How does high-temperature heating equipment simulate the service environment of ceramics? Expert Testing Strategies