Fluidized bed systems are renowned for their exceptional heat and mass transfer capabilities. They achieve this by suspending solid particles in an upward-flowing stream of gas or liquid, forcing the solids to behave like a fluid. This unique state offers uniform temperatures and efficient mixing but also introduces challenges related to particle erosion, energy consumption, and material loss.

The core trade-off of a fluidized bed system is clear: it offers unparalleled process uniformity and efficiency in exchange for higher operational complexity and the energy cost required to maintain the fluidized state.

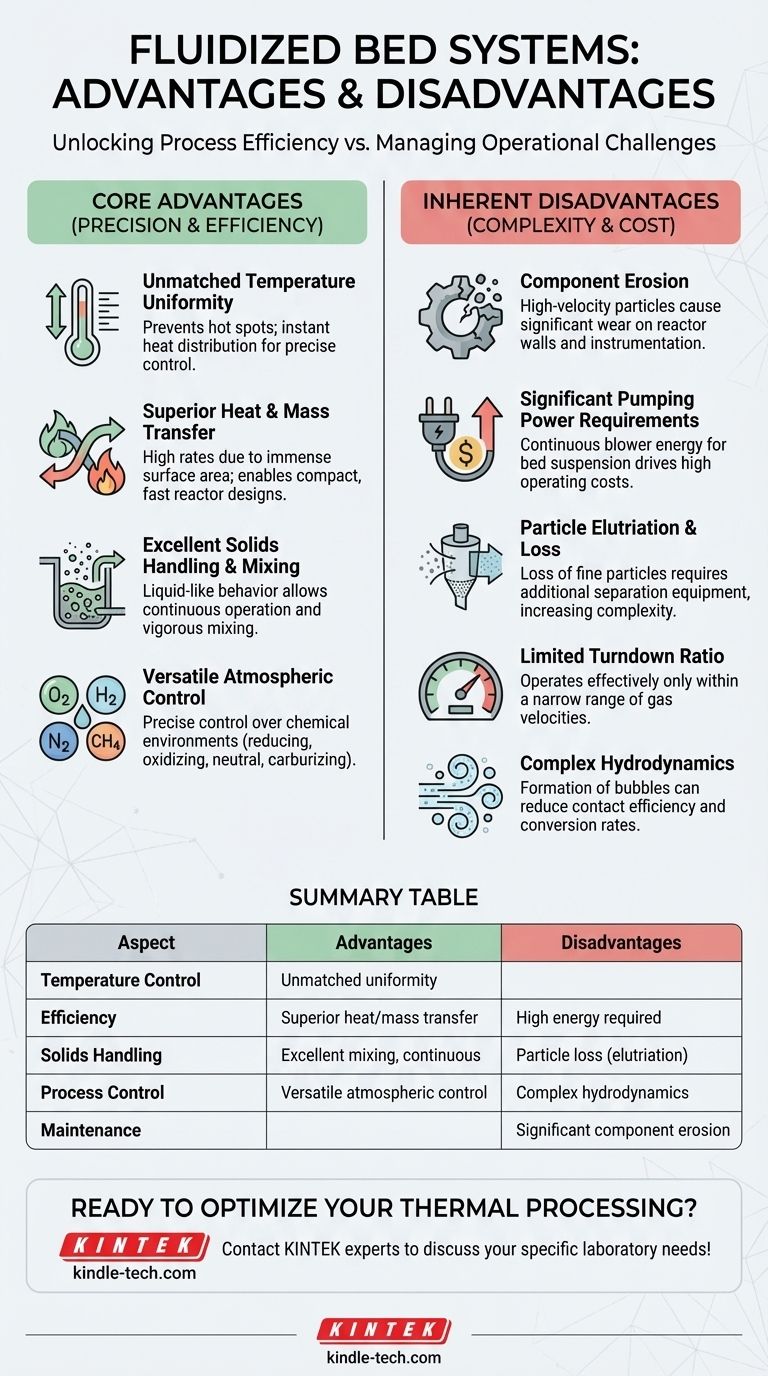

The Core Advantages of Fluidization

Fluidized beds are chosen for demanding applications where precise control and high throughput are critical. Their primary benefits stem directly from the fluid-like behavior of the solid particles.

Unmatched Temperature Uniformity

The rapid and constant motion of particles ensures that heat is distributed almost instantaneously throughout the bed. This prevents the formation of hot spots, which is critical for controlling temperature-sensitive chemical reactions or achieving uniform heat treatment of materials.

Superior Heat and Mass Transfer

The immense surface area of the suspended particles exposed to the fluidizing gas results in extremely high rates of heat and mass transfer. This allows for more compact reactor designs and faster processing times compared to packed bed or moving bed systems.

Excellent Solids Handling and Mixing

Because the solid bed behaves like a liquid, it can be easily drained, and fresh material can be added continuously. The inherent turbulence also provides vigorous mixing of solids, which is ideal for processes requiring consistent blend quality or catalytic reactions.

Versatile Atmospheric Control

The fluidizing gas is also the process atmosphere. This gives operators precise control over the chemical environment within the system, allowing for reducing, oxidizing, neutral, and carburizing atmospheres as required by the specific application.

Understanding the Inherent Disadvantages

While powerful, the dynamic nature of fluidized beds introduces significant operational and maintenance challenges that must be carefully considered.

Component Erosion

The constant movement and collision of hard particles at high velocities create a highly abrasive environment. This leads to significant wear and tear on the reactor walls, internal pipes, and instrumentation, making material selection and maintenance critical concerns.

Significant Pumping Power Requirements

Suspending the entire bed of particles requires a blower or pump to overcome the pressure drop across the bed. This continuous energy demand can represent a substantial portion of the system's total operating cost, especially for dense or deep beds.

Particle Elutriation and Loss

Fine particles can be easily carried out of the reactor by the upward-flowing gas stream, a phenomenon known as elutriation. This necessitates the use of downstream separation equipment, such as cyclones, to capture and often recycle these lost particles, adding to system cost and complexity.

Limited Turndown Ratio

Fluidized beds operate effectively only within a specific range of gas velocities—above the minimum fluidization velocity and below the velocity that causes excessive elutriation. This narrow operating window, or limited turndown ratio, can make them less flexible for processes with widely varying production rates.

Complex Hydrodynamics

The fluid dynamics within the bed, particularly the formation of bubbles, can be complex and difficult to predict. Large bubbles can allow gas to bypass the solid particles, reducing contact efficiency and lowering the conversion rate in chemical reactors.

Making the Right Choice for Your Application

Choosing whether to use a fluidized bed system requires balancing its unique process advantages against its operational demands.

- If your primary focus is precise temperature control and high reaction rates: A fluidized bed is an exceptional choice, especially for highly exothermic or temperature-sensitive processes where uniformity is paramount.

- If your primary focus is minimizing operational costs and maintenance: The high energy consumption and erosion rates may make simpler technologies like rotary kilns or packed beds a more suitable option.

- If your primary focus is handling solids with a wide particle size distribution: The tendency for fine particles to be lost and coarse particles to segregate requires careful design and may favor a different type of reactor.

Ultimately, selecting a fluidized bed system is a strategic decision that balances its superior process intensity against its demanding operational requirements.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Temperature Control | Unmatched uniformity, prevents hot spots | - |

| Efficiency | Superior heat/mass transfer, compact design | High energy/pumping power required |

| Solids Handling | Excellent mixing, continuous operation | Particle elutriation (loss of fines) |

| Process Control | Versatile atmospheric control (oxidizing, reducing, etc.) | Complex hydrodynamics, limited turndown ratio |

| Maintenance | - | Significant component erosion, wear and tear |

Ready to optimize your thermal processing with a fluidized bed system?

At KINTEK, we specialize in providing high-performance lab equipment, including robust fluidized bed reactors designed to maximize your process efficiency while managing operational challenges. Our systems are engineered with durable materials to combat erosion and are optimized for energy efficiency.

Whether you are in R&D, chemicals, or materials science, let KINTEK's expertise help you achieve precise temperature control and superior reaction rates.

Contact our experts today to discuss how a KINTEK fluidized bed system can meet your specific laboratory needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the requirements for polymer foam templates for reticulated MAX phase ceramics? Ensure Structural Integrity

- Is biomass a sustainable energy option? Unlocking a Truly Sustainable Energy Future

- What are the 3 types of heat transfer? Master Conduction, Convection & Radiation for Your Lab

- What is the difference between sputtering and plating? Choose the Right PVD Method for Your Application

- How stable is extracted RNA at various temperatures? A Guide to Safe Storage and Handling

- What are the two methods of control of corrosion? Master the Strategies for Metal Protection

- Can you separate the solid and liquid in a solution by filtering? No, and Here's Why

- What role does the sintering process play in TiO2 photocatalysts? Optimize Adhesion and Phase Transition