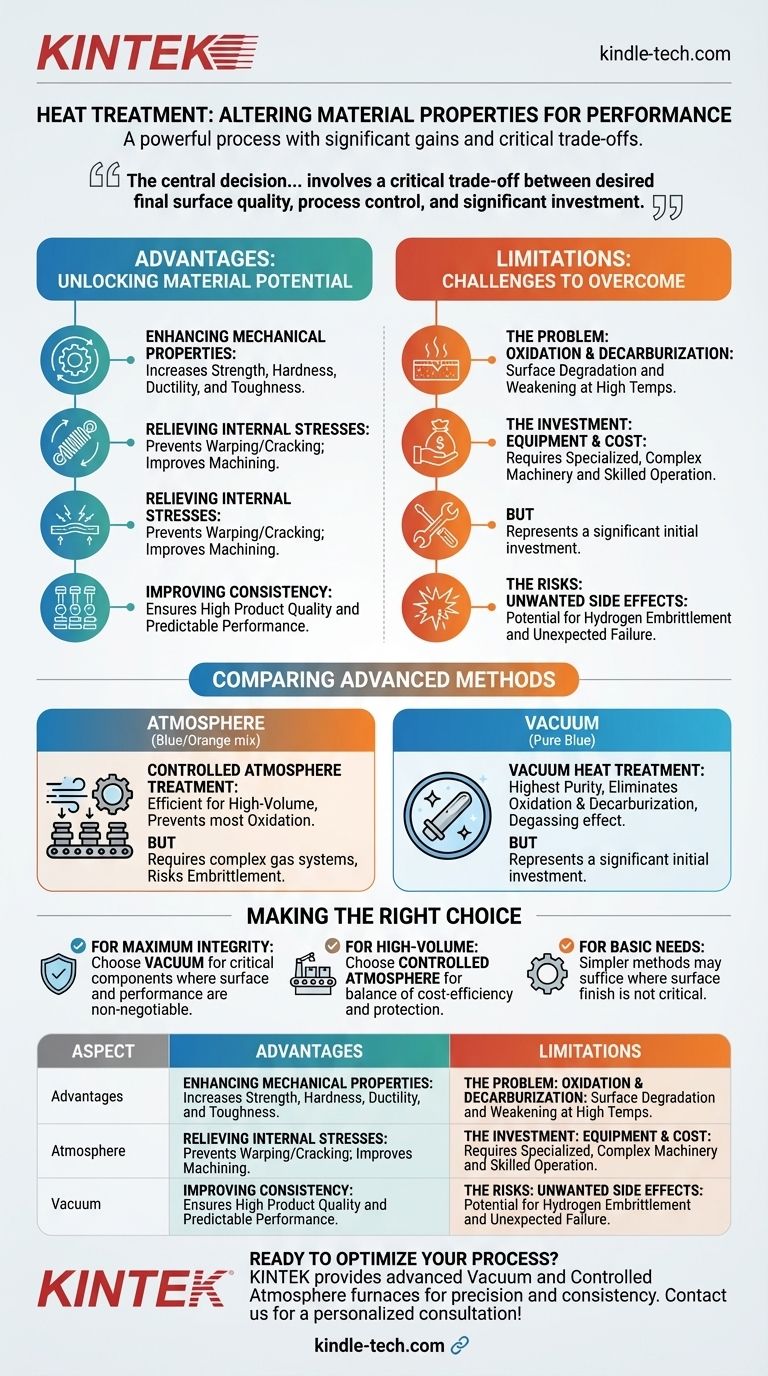

At its core, heat treatment is a powerful manufacturing process used to intentionally alter the physical and mechanical properties of a material. The primary advantages are significant gains in strength, durability, and workability, while the limitations revolve around the cost and complexity of the equipment required to control the process and prevent undesirable side effects like oxidation.

The central decision in heat treatment is not simply whether to use it, but which method to employ. The choice involves a critical trade-off between the desired final surface quality, the degree of process control needed, and the significant investment in equipment and operational skill.

The Fundamental Advantages of Heat Treatment

Heat treatment is employed because it imparts properties to a material that it would not otherwise possess. This control is essential for creating high-performance, reliable parts.

Enhancing Mechanical Properties

The most common reason for heat treatment is to change a material's mechanical characteristics. This includes increasing strength and hardness for wear resistance, improving ductility to make a material less brittle, and enhancing overall toughness.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or machining introduce internal stresses into a material. Heat treatment can relieve these stresses, making the part more stable and less prone to warping or cracking over time, which also makes subsequent machining easier.

Improving Material Consistency

Modern heat treatment methods offer excellent process control. This ensures that the desired properties are achieved consistently across large batches, leading to higher product quality, better qualification rates, and predictable performance.

Understanding the Trade-offs and Limitations

While the benefits are clear, the process is not without its challenges. The primary limitations stem from the chemical reactions that occur at high temperatures and the complexity of the equipment needed to prevent them.

The Problem: Oxidation and Decarburization

When steel is heated in the presence of oxygen, its surface oxidizes (forms scale) and can lose carbon content (decarburization), which weakens the surface. Preventing this is the main driver behind advanced heat treatment technologies.

The Investment: Equipment and Operational Cost

Basic heat treatment can be done in open-air furnaces, but for high-quality results, specialized equipment is necessary. This equipment can be complicated, representing a large initial investment and requiring high technical skill to operate effectively.

The Risks: Unwanted Side Effects

Certain processes carry specific risks. For example, using a hydrogen-rich atmosphere to prevent oxidation can lead to hydrogen embrittlement in some steels, a phenomenon where the metal becomes brittle and fails unexpectedly.

Comparing Advanced Methods: Atmosphere vs. Vacuum

To overcome the basic problem of oxidation, two primary advanced methods are used: controlled atmosphere and vacuum heat treatment.

Controlled Atmosphere Treatment

This method involves displacing the air in a furnace with a specific, carefully managed mixture of gases. The goal is to create an environment that actively prevents oxidation and decarburization.

Its primary advantage is efficiency for high-volume production, offering significant savings in manpower and processing steps compared to older methods. However, it requires complex gas management systems and carries the risk of side effects like hydrogen embrittlement if not properly controlled.

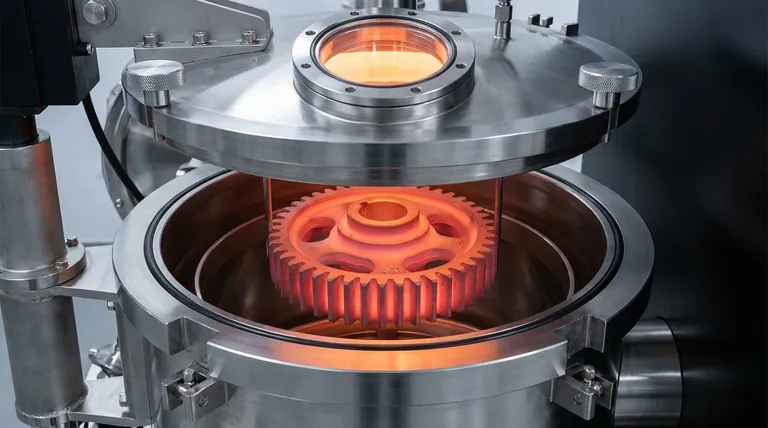

Vacuum Heat Treatment

This is the highest-purity method. The workpiece is heated in a furnace from which virtually all air and other gases have been removed.

This process completely eliminates oxidation and decarburization, resulting in a bright, clean surface that requires no post-process cleaning. It also has a degassing effect, removing trapped gases like hydrogen to improve ductility and fatigue life. Vacuum furnaces provide the best repeatability and are inherently safer as they avoid flammable or reactive gases.

Making the Right Choice for Your Goal

Your specific objective determines which process is the most logical and cost-effective choice.

- If your primary focus is maximum performance and surface integrity: Vacuum heat treatment is the definitive choice for critical components where a perfect surface and optimal mechanical properties are non-negotiable.

- If your primary focus is high-volume production with good quality: Controlled atmosphere treatment provides an excellent balance of cost-efficiency and protection against most surface degradation.

- If your primary focus is basic stress relief or property changes where surface finish is not critical: Simpler, non-controlled atmosphere methods can be sufficient, avoiding the investment in more complex systems.

Ultimately, selecting the right heat treatment method is a strategic decision that directly impacts the final quality, cost, and performance of your product.

Summary Table:

| Aspect | Advantages | Limitations |

|---|---|---|

| Mechanical Properties | Increases strength, hardness, ductility, and toughness. | Requires precise control to avoid unwanted side effects. |

| Internal Stress | Relieves stresses from welding/casting, prevents warping. | Process can be complex and requires skilled operation. |

| Surface Quality | Advanced methods (vacuum) prevent oxidation, decarburization. | High-quality equipment represents a significant investment. |

| Consistency & Safety | Ensures batch consistency; vacuum method is inherently safer. | Atmosphere control carries risks like hydrogen embrittlement. |

Ready to optimize your heat treatment process and achieve superior material performance?

At KINTEK, we specialize in providing advanced laboratory equipment, including vacuum and controlled atmosphere furnaces, to help you overcome the limitations of oxidation and decarburization. Our solutions are designed for laboratories that demand precision, consistency, and impeccable surface integrity for their critical components.

Let our experts help you select the right equipment to enhance your product's strength, durability, and quality. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How long does it take to do a heat treatment? A Full Day for a 100% Bed Bug Kill Rate

- Is pyrolysis oil harmful? Understanding the Risks of This Reactive Biofuel

- What is difference between FTIR and IR? The Revolutionary Leap in Modern Spectroscopy

- Which type of evaporator is used in chemical industry? Choose the Right Evaporator for Your Process

- What temperature is approximately equal to sintering? A Guide Based on Your Material's Melting Point

- Why are ULT freezers critical for biological sciences and vaccine transport? Ensure Sample Integrity and Vaccine Efficacy

- What is the difference between cast and sintered parts? Choose the Right Metal Forming Process

- What is the history of magnetron sputtering? The 1974 Breakthrough That Revolutionized Thin-Film Coating