The primary advantages of a water circulating vacuum pump are its simple and robust design, its ability to handle condensable vapors and corrosive gases that would damage other pumps, and its isothermal compression process. Because it uses a ring of water for both sealing and compression, it requires no oil lubrication and has no metal-on-metal friction surfaces, leading to high reliability and minimal maintenance.

A water circulating vacuum pump is not designed to achieve the deepest vacuum. Instead, its core value lies in its exceptional durability and its unique ability to safely and effectively handle difficult gas loads, making it an invaluable tool for specific industrial and laboratory applications.

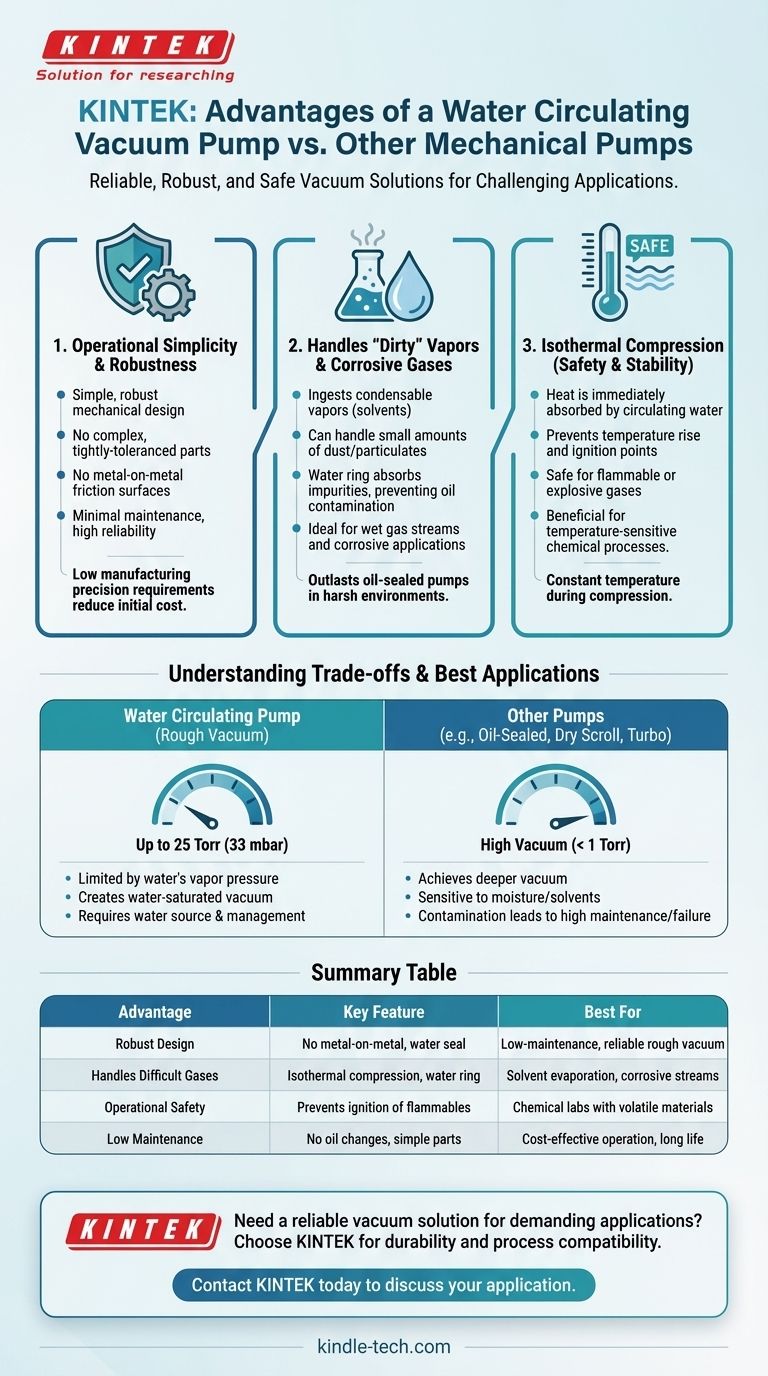

How Operational Simplicity Drives Key Advantages

The design of a water circulating vacuum pump, often called a liquid ring pump, is fundamentally different from oil-sealed or dry mechanical pumps. An offset impeller spins within a casing, flinging a ring of water against the outer wall. The spaces between the impeller vanes and this water ring expand and contract, drawing in gas, compressing it, and then expelling it.

Simple and Robust Mechanical Design

The pump's structure is remarkably simple with low manufacturing precision requirements compared to other pump types. There are no complex, tightly-toleranced parts like the tips of a scroll pump or the vanes of an oil-sealed rotary vane pump.

This simplicity directly translates to lower initial cost and significantly reduced maintenance needs. With no metal-on-metal friction, wear and tear is minimal.

Isothermal (Constant Temperature) Compression

As gas is drawn into the pump and compressed, the heat generated is immediately absorbed by the large volume of circulating water.

This isothermal compression is a critical advantage when handling flammable or explosive gases, as it prevents temperatures from rising to a dangerous ignition point. It also benefits temperature-sensitive chemical processes.

Unmatched Ability to Handle "Dirty" Vapors

This is arguably the most important advantage. The water ring can ingest condensable vapors (like solvents) and even small amounts of dust or particulates without being damaged.

In an oil-sealed pump, these vapors would contaminate the oil, drastically reducing performance and requiring frequent, costly oil changes. A water circulating pump simply absorbs them into the water, which can then be handled accordingly.

Understanding the Trade-offs and Limitations

No technology is a universal solution. The strengths of a water circulating pump come with clear limitations that make it unsuitable for certain tasks.

Vacuum Level Limitations

A water circulating pump provides a rough vacuum. Its ultimate pressure is limited by the vapor pressure of the water being used, which is typically around 25 Torr (33 mbar) at room temperature.

It cannot be used for high-vacuum applications that require pressures below 1 Torr. For those tasks, oil-sealed rotary vane pumps, dry scroll pumps, or turbomolecular pumps are necessary.

Water Consumption and Contamination

While "circulating" models are much more efficient than single-pass aspirators, they still require a water source. The primary concern is the disposal of the seal water.

If the pump is used to pull vapors from a chemical process, those chemicals will contaminate the water. This creates an environmental disposal issue that must be managed, potentially adding cost and complexity.

Unsuitability for Water-Sensitive Systems

Because the sealing fluid is water, the vacuum produced is saturated with water vapor. This makes the pump completely unsuitable for any process that is sensitive to moisture, such as in certain electronics manufacturing or freeze-drying applications.

Making the Right Choice for Your Application

Selecting the correct vacuum pump requires matching the technology's strengths to your primary goal.

- If your primary focus is low-cost, reliable rough vacuum for general use: The pump's simplicity, low initial cost, and minimal maintenance make it an excellent workhorse for applications like filtration, degassing, or rotary evaporation in a lab.

- If your primary focus is pumping solvent vapors, corrosive gases, or wet gas streams: This is the ideal application for a water circulating pump, as it will outperform and outlast oil-sealed pumps that would quickly fail in these conditions.

- If your primary focus is achieving a high or ultra-high vacuum: You must choose a different technology, such as a dry scroll, rotary vane, or turbo pump, as a water ring pump is fundamentally incapable of reaching these low pressures.

Ultimately, choosing a water circulating vacuum pump is a strategic decision to prioritize durability and process compatibility over achieving the deepest possible vacuum.

Summary Table:

| Advantage | Key Feature | Best For |

|---|---|---|

| Robust Design | No metal-on-metal friction, water seal | Low-maintenance, reliable rough vacuum |

| Handles Difficult Gases | Isothermal compression, water ring absorbs vapors | Solvent evaporation, pumping corrosive or wet streams |

| Operational Safety | Prevents ignition of flammable gases | Chemical and process labs with volatile materials |

| Low Maintenance | No oil changes, simple mechanical parts | Cost-effective operation and long service life |

Need a reliable vacuum solution for demanding applications?

If your lab processes involve solvents, corrosive gases, or requires a robust, low-maintenance rough vacuum pump, a water circulating vacuum pump from KINTEK could be the ideal choice. Our expertise in lab equipment ensures you get a solution tailored to handle your specific gas loads safely and efficiently, maximizing uptime and minimizing maintenance costs.

Contact KINTEK today to discuss your application and find the perfect vacuum pump for your laboratory's needs.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- Why is it sometimes advisable to use water bath for evaporation instead of direct heating? Ensure Safety and Precision for Your Lab

- Why are constant temperature water baths used in refractory testing? Accelerate MgO Hydration & Binder Evaluation

- What is the necessity of a circulating water bath in chlorate production? Optimize Yield & Purity with Precision

- Why is a circulating water cooling system required for photocatalytic hydrogen peroxide? Stability and Yield Explained

- What is the function of a high-temperature constant temperature bath? Key Role in HTC Coating on AA 6061 Alloy

- What roles do water-cooling systems and stainless steel bottom plates serve? Master Heat Extraction in Solidification

- What role does a constant temperature water bath system play in stainless steel electropolishing? Essential Lab Control

- What is the role of low-temperature cooling baths in bio-oil collection? Maximize Yield Through Rapid Quenching