At its core, a water circulating vacuum pump operates by using a rotating impeller to create a ring of liquid—typically water—that acts as a piston. This ring of water traps, compresses, and then expels gas molecules from a connected system. The "circulating" aspect refers to the pump's ability to reuse its working fluid from an integrated reservoir, making it highly efficient for laboratory settings.

The pump's design ingeniously replaces a traditional mechanical piston with a dynamic ring of water. An off-center (eccentric) impeller creates expanding and contracting chambers between its blades and this water ring, generating a reliable vacuum through a continuous cycle of gas intake and expulsion.

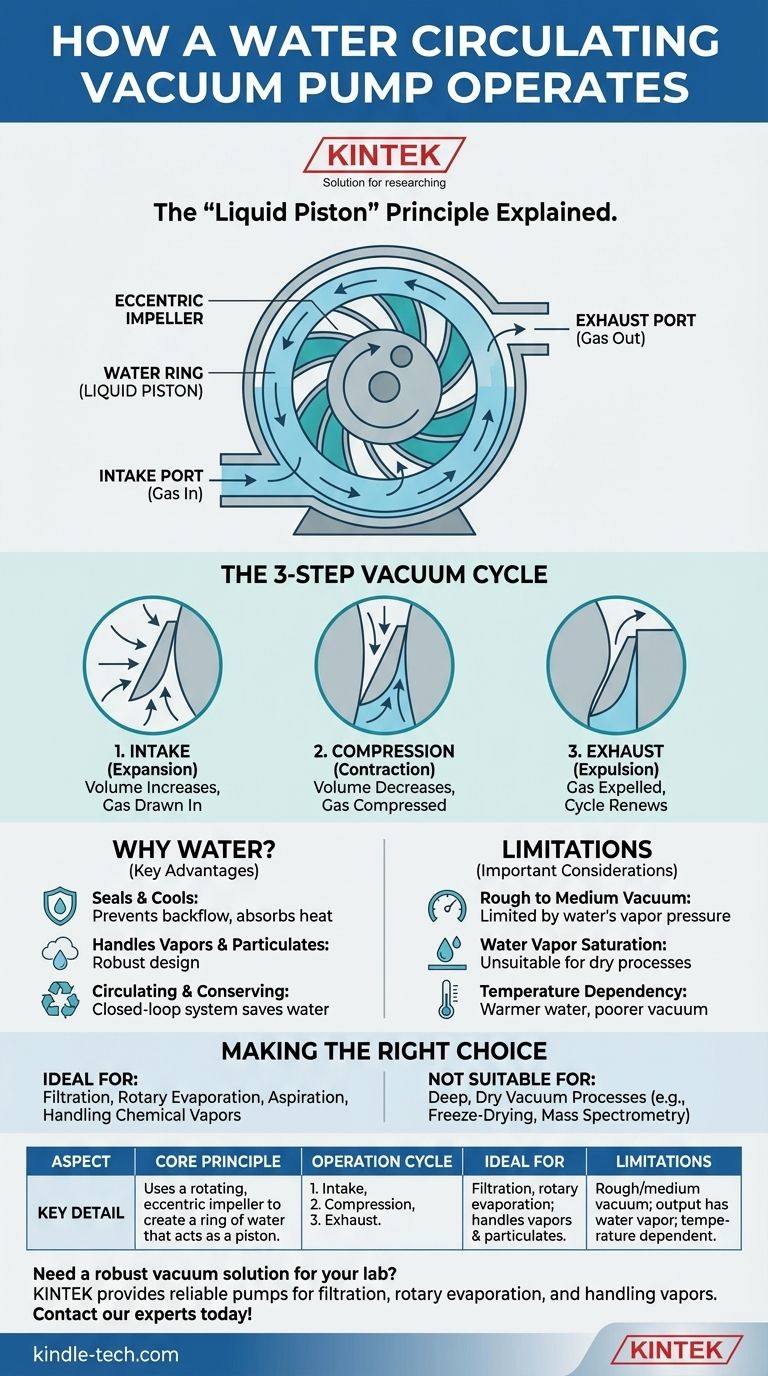

The Core Principle: The Liquid Piston in Action

The entire operation hinges on a clever mechanical setup that uses fluid dynamics to move gas. This process can be broken down into a few key components and steps.

Creating the Water Ring

When the pump is turned on, an electric motor spins an impeller located inside a cylindrical casing. The casing is partially filled with water. Centrifugal force throws this water outward against the casing wall, forming a consistent, concentric liquid ring.

The Eccentric Impeller

The key to the pump's function is that the impeller is mounted eccentrically, or off-center, within the casing. This means the hub of the impeller is closer to one side of the casing than the other.

This off-center placement creates a crescent-shaped void between the impeller hub and the inner surface of the water ring.

The Three-Step Vacuum Cycle

As the impeller's blades rotate through this crescent-shaped space, the volume of the individual pockets between the blades changes continuously. This creates a three-step cycle that is repeated for each blade with every rotation.

1. Intake (Expansion)

As a blade moves through the wider part of the crescent, the space between it, the impeller hub, and the water ring increases. This expansion creates a low-pressure zone, drawing gas in from the system through the suction port.

2. Compression (Contraction)

As the blade continues its rotation into the narrower part of the crescent, the water ring forces its way back toward the hub. This decreases the volume of the pocket, compressing the trapped gas.

3. Exhaust (Expulsion)

Finally, as the pocket reaches its minimum volume near the exhaust port, the compressed gas is forced out of the pump. The cycle then begins again, creating a continuous and smooth vacuum.

Why Water is the Working Fluid

The use of water is not arbitrary; it serves multiple critical functions that define the pump's performance and utility.

Sealing and Cooling

The water ring effectively seals the small chambers between the blades, preventing gas from leaking back and ensuring a stable vacuum. It also absorbs the heat generated during gas compression, keeping the pump cool.

Handling Vapors and Particulates

This design is remarkably robust. It can handle moisture, solvent vapors, and even small particulates that would damage or destroy other types of vacuum pumps, like oil-sealed rotary vane pumps.

The "Circulating" Advantage

Many of these pumps include a water tank or reservoir. The discharged water and gas are separated, and the water is returned to the tank to be reused. This closed-loop system conserves a significant amount of water, a major advantage for labs with limited water supply or low pressure.

Understanding the Trade-offs and Limitations

While highly useful, this design is not suitable for all applications. Understanding its inherent limitations is crucial for proper use.

Vacuum Level

Water circulating pumps produce a rough to medium vacuum. The ultimate pressure is limited by the vapor pressure of the water itself. As the pressure in the system approaches the water's vapor pressure, the water begins to boil, and the pump cannot achieve a deeper vacuum.

Water Vapor

The vacuum produced will always be saturated with water vapor. This makes it unsuitable for processes that are sensitive to moisture.

Temperature Dependency

The pump's performance is directly tied to the temperature of the circulating water. Warmer water has a higher vapor pressure, which means it will start to boil at a higher pressure, resulting in a poorer ultimate vacuum. For best performance, the water should be kept as cool as possible.

Making the Right Choice for Your Application

Use these guidelines to determine if a water circulating vacuum pump meets your needs.

- If your primary focus is general lab work like filtration, rotary evaporation, or aspiration: This pump is an excellent, robust, and low-maintenance choice.

- If your primary focus is achieving a deep, dry vacuum for processes like freeze-drying or mass spectrometry: This pump is unsuitable due to its vacuum level and water vapor limitations.

- If your primary focus is resource conservation and handling chemical vapors: The water-saving circulation and ability to handle contaminants make it a highly practical and cost-effective option.

By understanding this elegant "liquid piston" principle, you can effectively leverage the pump's unique strengths for a wide range of robust, everyday vacuum tasks.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Uses a rotating, eccentric impeller to create a ring of water that acts as a piston. |

| Operation Cycle | 1. Intake (Expansion) 2. Compression 3. Exhaust (Expulsion) |

| Ideal For | Filtration, rotary evaporation, aspiration; handles vapors & particulates well. |

| Limitations | Rough to medium vacuum; output contains water vapor; performance depends on water temperature. |

Need a robust and efficient vacuum solution for your lab? KINTEK specializes in lab equipment and consumables, providing reliable water circulating vacuum pumps perfect for filtration, rotary evaporation, and handling chemical vapors. Our expertise ensures you get the right equipment for enhanced efficiency and cost-effectiveness. Contact our experts today to find the ideal vacuum pump for your laboratory needs!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the function of high-shear or magnetic stirrers in co-precipitation? Master Composite Metal Oxide Synthesis

- Why refractory metals are used in construction of furnaces? Unlock Extreme Temperature Performance

- What is the strength of a quartz tube? Withstand 1,000 PSI in High-Temp, High-Purity Applications

- What is the test for refractory material? Essential Tests for High-Temperature Performance

- How do high-strength chrome steel grinding balls influence HEA powder preparation? Optimize Mechanical Alloying Results

- What is the function of a PID temperature control system? Ensure Stability in Nuclear Simulations

- Why is a Quencher vital for the analysis of products in high-temperature experiments? Ensure Data Integrity

- Why select tungsten carbide grinding balls for chromium & silicon? Maximize Milling Power and Purity