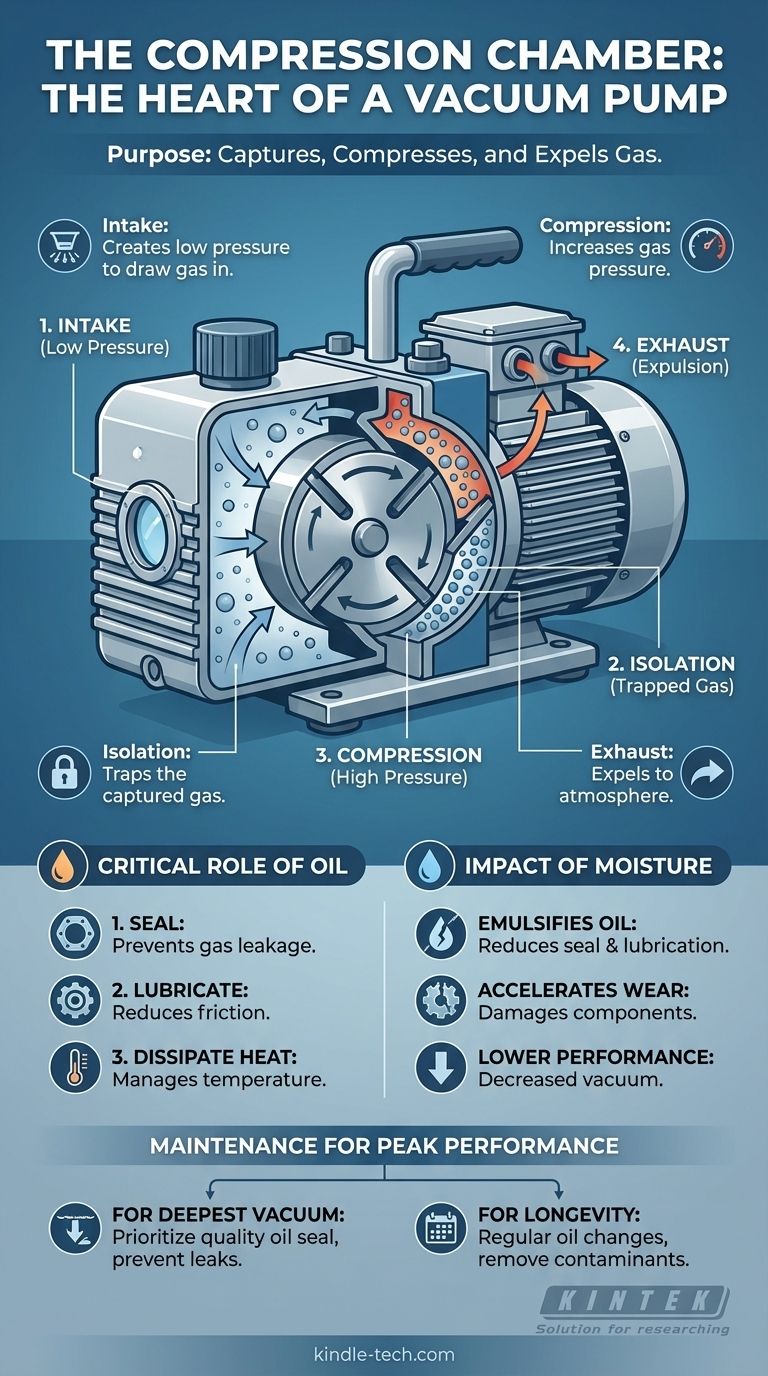

At its core, the compression chamber is the operational heart of a rotary vane vacuum pump. It is the precisely machined space that houses the rotating components responsible for capturing gas from a system, compressing it, and finally expelling it to the atmosphere.

The term "compression chamber" can seem counterintuitive for a device that creates a vacuum. However, its purpose is twofold: it first creates a low-pressure void to draw gas in, and then it compresses that captured gas to a pressure high enough to be pushed out of the pump.

How the Compression Chamber Creates a Vacuum

The entire vacuum process occurs in a continuous, four-stage cycle within the compression chamber. This cycle is driven by a rotor with sliding vanes, which is mounted off-center within the cylindrical chamber.

The Role of the Eccentric Rotor

The key to the chamber's function is the eccentrically mounted rotor. Because it is not perfectly centered, the gap between the rotor's surface and the chamber wall constantly changes as it spins.

This changing gap creates pockets of expanding and contracting volume, which is the fundamental mechanism for moving gas.

The Intake Phase: Creating Low Pressure

As the rotor turns, the spring-loaded vanes slide outward, staying in constant contact with the chamber wall. On the intake side, this motion creates an expanding pocket of space.

This expansion lowers the pressure inside the pocket to below that of the connected system, creating a pressure differential. Gas molecules from the system are then drawn into this low-pressure region, effectively evacuating the system.

The Isolation Phase: Trapping the Gas

As the rotor continues its rotation, the trailing vane passes the inlet port. This action seals off the pocket of captured gas, isolating it from both the inlet and the outlet.

The Compression and Exhaust Phase

Now, as the trapped pocket of gas is carried toward the exhaust side of the chamber, the eccentric mounting of the rotor causes the volume to shrink.

This shrinking volume compresses the gas, dramatically increasing its pressure. Once the pressure of the trapped gas exceeds the pressure of the exhaust valve spring (and the outside atmosphere), it forces the valve open and is expelled from the pump. This cycle repeats thousands of times per minute.

Understanding Key Operational Factors

The mechanical process within the compression chamber relies on more than just moving parts. Certain factors are critical for its efficiency and longevity.

The Critical Role of Oil

In an oil-sealed rotary vane pump, a thin film of specialized vacuum pump oil is essential. This oil serves three distinct purposes inside the chamber.

First, it creates a crucial seal between the tips of the vanes and the chamber wall, preventing gas from leaking back and compromising the vacuum. Second, it lubricates all moving parts. Third, it helps dissipate the heat generated by the compression of the gas.

The Impact of Moisture and Contaminants

The references correctly note that the pump removes moisture. However, this moisture is a contaminant. When water vapor is drawn into the compression chamber, it can emulsify with the oil.

This contaminated oil loses its ability to seal and lubricate effectively, leading to a significant drop in pump performance and accelerated wear on the chamber, rotor, and vanes.

Making the Right Choice for Maintenance

Properly caring for the components within the compression chamber is directly linked to the performance and lifespan of your vacuum pump.

- If your primary focus is achieving the deepest possible vacuum: Your priority must be the quality of the oil seal, which means using clean, correct-viscosity vacuum oil and preventing external system leaks.

- If your primary focus is pump longevity and reliability: Your priority should be regular oil changes to remove moisture and abrasive contaminants before they can damage the precisely machined surfaces of the chamber and rotor.

Ultimately, a clean, well-sealed compression chamber is the foundation of high-performance vacuum generation.

Summary Table:

| Function | Key Component | Purpose |

|---|---|---|

| Intake | Expanding chamber volume | Creates low pressure to draw gas in |

| Isolation | Rotor vanes | Traps the captured gas |

| Compression | Shrinking chamber volume | Increases gas pressure for exhaust |

| Exhaust | Exhaust valve | Expels compressed gas to atmosphere |

Ensure your lab's vacuum pumps operate at peak performance and longevity. The precision of the compression chamber is critical for reliable results. KINTEK specializes in high-quality lab equipment, including vacuum pumps and consumables, to meet your specific laboratory needs. Our experts can help you select the right pump and provide maintenance support to protect your investment. Contact our team today to discuss your vacuum requirements!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the applications of rotary vane vacuum pump? Essential for Industrial & Lab Vacuum Systems

- What is the lining of a furnace made of? Key Materials for Extreme Heat Containment

- What is the function of a K-type thermocouple in the control of diamond film deposition parameters? Master Thermal Control

- How does the pumping system contribute to TDS analysis? Achieve Precise UHV for High-Sensitivity Detection

- Can you run a pellet stove without a vacuum switch? The Critical Safety Risks Explained

- Why is a high-purity nitrogen flow control device necessary for pyrolysis? Ensure Safety and Superior Product Yield

- Why are zirconia ball mill jars required for zirconium halide electrolytes? Ensure Pure, High-Conductivity Synthesis

- What is the function of a magnetic stirrer in SiO2FexOy synthesis? Achieve Molecular Homogeneity in Sol-Gel Processes