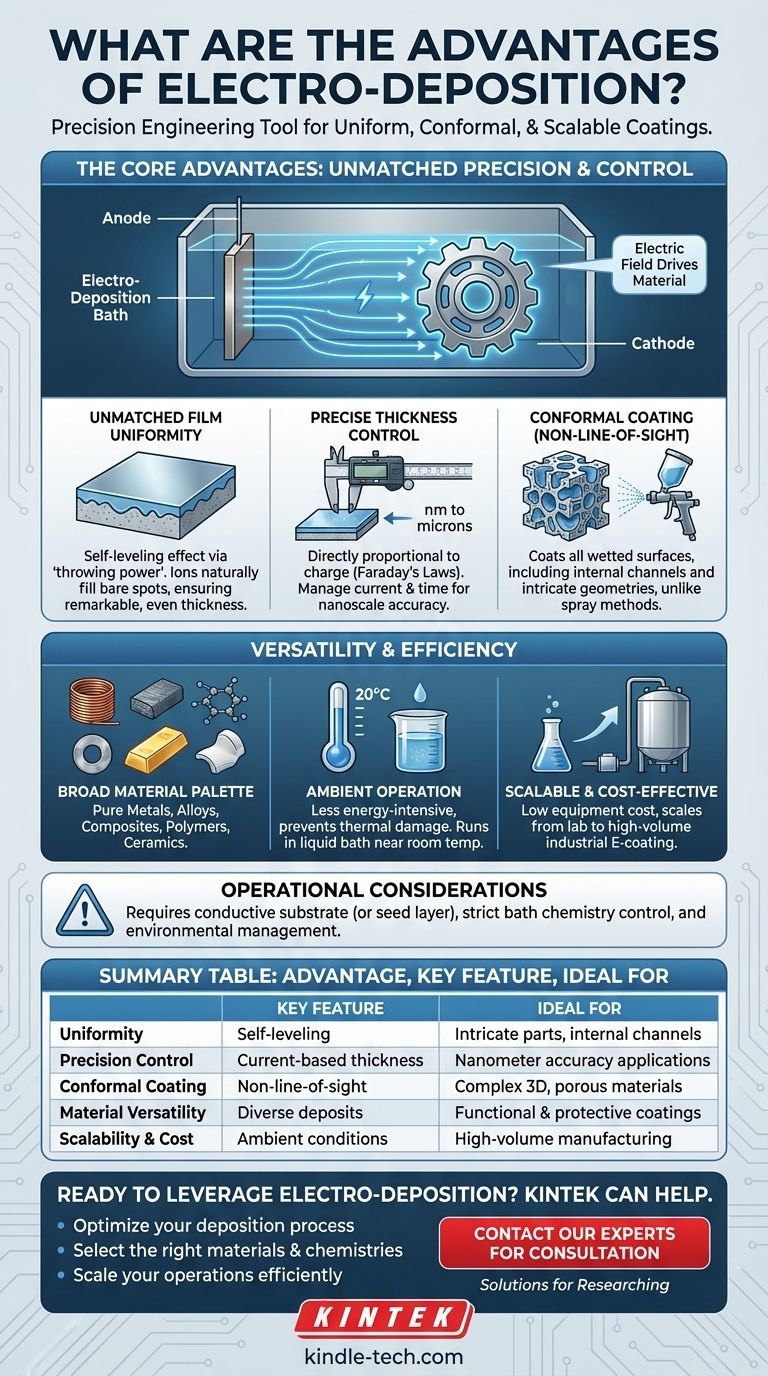

The primary advantages of electro-deposition are its exceptional ability to create highly uniform, conformal coatings on complex shapes, its precise control over film thickness at the nanometer scale, and its cost-effectiveness at industrial volumes. This process uses an electric field to drive charged particles onto a conductive surface, resulting in a dense, pure, and well-adhered film that is difficult to achieve with other methods.

At its core, electro-deposition is not just a coating technique but a precision engineering tool. It leverages fundamental electrochemical principles to build films atom-by-atom, offering a level of control and uniformity on intricate geometries that line-of-sight methods simply cannot match.

Why Electro-Deposition Excels in Precision Coating

The true power of electro-deposition lies in how it uses an electric field to control material placement. This leads to several distinct, high-value advantages over alternative methods like physical vapor deposition (PVD), chemical vapor deposition (CVD), or simple painting.

Unmatched Film Uniformity

The process has excellent "throwing power," a term describing its ability to create a coating of even thickness across an entire part.

The electric field naturally directs ions to areas of the substrate with the least electrical resistance—the bare spots. As a spot gets coated, its resistance increases, automatically redirecting incoming ions to adjacent uncoated areas. This creates a self-leveling effect that ensures remarkable uniformity.

Precise Control Over Thickness and Morphology

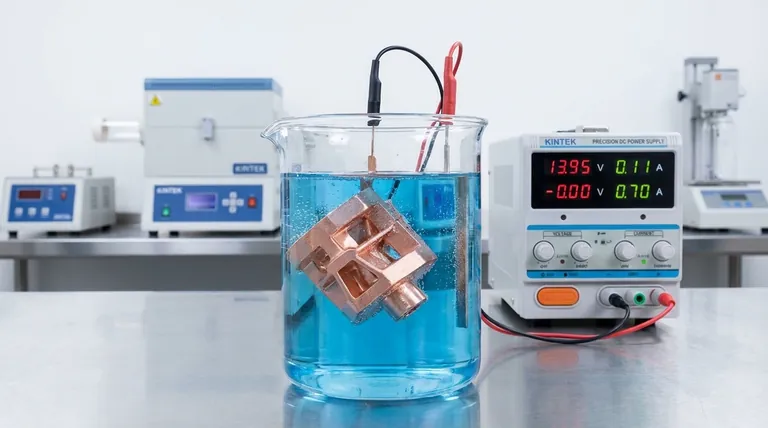

The thickness of the deposited film is directly proportional to the total electrical charge passed, governed by Faraday's laws of electrolysis.

This means you can precisely control film thickness—from a few nanometers to many microns—by simply managing the applied current and deposition time. Furthermore, by adjusting bath chemistry and additives, you can control the film's microstructure, such as whether it is crystalline or amorphous.

Conformal Coating on Complex Geometries

Electro-deposition is not a "line-of-sight" process. The electrolyte bath surrounds the part, allowing the electric field to reach all wetted surfaces.

This makes it exceptionally effective for coating internal channels, porous materials, and intricate, complex shapes where spray or vapor-based methods would fail to reach.

The Versatility of Electro-Deposition

Beyond its precision, the technique is highly adaptable to different materials, scales, and operating environments, making it a cornerstone of modern manufacturing.

A Broad Palette of Materials

The process is not limited to simple metals. It can be used to deposit a wide range of materials, including:

- Pure Metals: Copper, nickel, zinc, gold, chromium

- Alloys: Bronze, brass, nickel-cobalt

- Composites: Metal-matrix composites by co-depositing particles

- Polymers: E-coating (electrocoating) for corrosion protection

- Ceramics: Through electrophoretic deposition (EPD)

Operation at or Near Room Temperature

Unlike PVD or CVD, which often require high vacuum and elevated temperatures, most electro-deposition processes run in a liquid bath under ambient conditions.

This makes the process less energy-intensive and prevents thermal damage to sensitive substrates, expanding its range of applications.

Scalability and Cost-Effectiveness

The equipment for electro-deposition is generally less expensive than high-vacuum or high-temperature systems.

The process scales efficiently from small, lab-based setups for research to enormous, automated tanks for industrial applications like the automotive industry's E-coating process, providing robust corrosion protection at a low unit cost.

Understanding the Trade-offs and Limitations

No process is perfect. To use electro-deposition effectively, you must be aware of its fundamental requirements and operational challenges.

The Substrate Must Be Conductive

This is the most significant limitation. The part being coated must be able to conduct electricity to act as the cathode. Non-conductive materials like plastics or ceramics must first be coated with a thin, conductive "seed layer" before deposition can occur.

Bath Chemistry Requires Strict Control

The electrolyte bath is a complex chemical system. Its performance is highly sensitive to temperature, pH, ion concentration, and contamination. Maintaining the bath requires consistent monitoring and chemical replenishment, adding to the operational overhead.

Potential Environmental Concerns

Many traditional plating baths use hazardous chemicals, such as heavy metals or cyanides. This necessitates robust safety protocols, ventilation, and wastewater treatment systems to mitigate environmental impact and ensure worker safety.

Making the Right Choice for Your Goal

Selecting a coating method depends entirely on your project's specific requirements for performance, geometry, and cost.

- If your primary focus is coating complex, non-line-of-sight geometries with high uniformity: Electro-deposition is almost certainly the superior choice.

- If your primary focus is achieving precise, nanometer-scale thickness control on a conductive part: This method offers unparalleled control through simple electrical parameters.

- If your primary focus is high-volume, cost-effective corrosion protection for metal parts: Industrial electro-deposition (E-coating) is a proven and dominant technology.

- If you are working with a non-conductive substrate and cannot apply a seed layer: You must consider alternative methods like PVD, CVD, or spray coating.

By understanding its core advantages and limitations, you can leverage electro-deposition as a powerful and precise tool for advanced materials engineering.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Uniformity | Self-leveling effect via electric field | Coating intricate parts, internal channels |

| Precision Control | Thickness controlled by electrical current | Applications requiring nanometer accuracy |

| Conformal Coating | Non-line-of-sight process in electrolyte bath | Complex 3D shapes and porous materials |

| Material Versatility | Deposits metals, alloys, composites, polymers | Broad range of functional and protective coatings |

| Scalability & Cost | Operates at ambient conditions; lower equipment cost | High-volume manufacturing like automotive E-coating |

Ready to leverage electro-deposition for your precision coating needs?

At KINTEK, we specialize in providing advanced laboratory equipment and consumables to support your materials engineering projects. Whether you are developing new coatings in R&D or scaling up for production, our expertise and solutions can help you achieve superior results with electro-deposition.

We help you:

- Optimize your deposition process for maximum uniformity and adhesion.

- Select the right materials and chemistries for your specific application.

- Scale your operations efficiently from lab to production.

Let's discuss how electro-deposition can solve your coating challenges. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating