The primary advantages of electron beam radiation stem from its rapid, precise energy delivery and its characteristically shallow penetration depth. This makes it exceptionally useful for applications like treating surface-level tumors where sparing underlying healthy tissue is critical, and for the high-speed sterilization of products without degrading their material properties.

The core benefit of electron beam technology is its controlled, surface-focused energy deposition. This allows for highly effective treatment or sterilization of a target while protecting whatever lies beneath it, whether that's healthy organs or the integrity of a medical device.

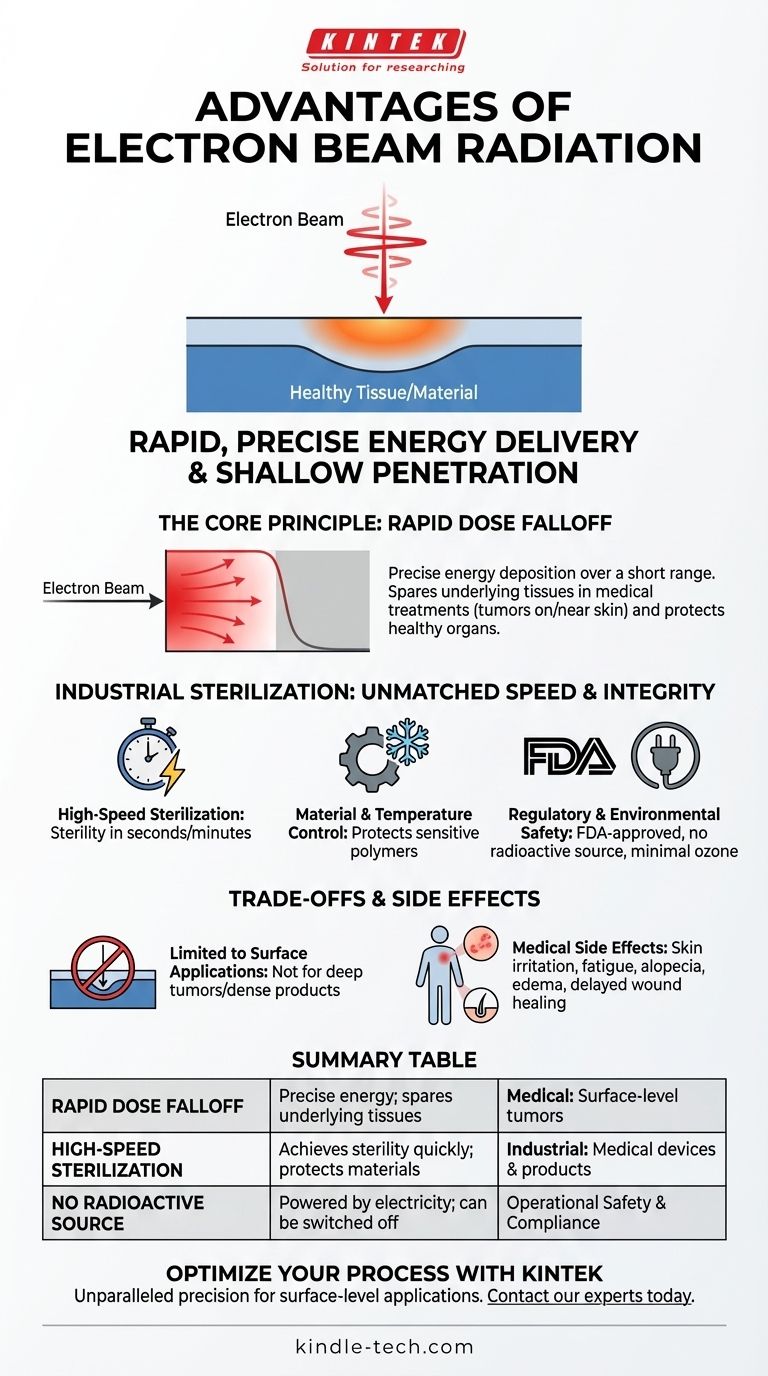

The Core Principle: Rapid Dose Falloff

Why Penetration Depth Matters

The defining characteristic of an electron beam is that it deposits its energy over a very short, well-defined range within a material. Electrons lose their energy quickly as they interact with tissue or other substances.

This results in a rapid dose falloff, meaning the radiation dose drops sharply just beyond the intended target depth.

Sparing Underlying Tissues

In a medical context, this precision is a significant advantage. It allows clinicians to deliver a high, therapeutic dose of radiation to a tumor on or near the skin.

Because the dose falls off so quickly, the radiation exposure to deeper, healthy organs and tissues is minimized, reducing the risk of collateral damage.

Key Advantages in Industrial Sterilization

Unmatched Speed and Efficiency

Electron beam sterilization is an exceptionally fast process, with a very high dosing rate. This allows for a high level of sterility assurance to be achieved in seconds or minutes.

This speed means products can be processed, confirmed sterile, and released for shipment almost immediately, dramatically improving supply chain efficiency.

Material Integrity and Temperature Control

Unlike some other methods, electron beam radiation allows for precise temperature control during the process. This is critical for sensitive materials.

It is known for protecting the properties of polymers and other materials, preventing the degradation that can occur with other sterilization techniques.

Regulatory and Environmental Safety

Electron beam sterilization is an FDA-approved and internationally accepted process.

From an operational safety standpoint, it has a major advantage: it does not require a localized radioactive source like Cobalt-60. The system is powered by electricity and can be simply switched off. It also has a minimal atmospheric effect, releasing only a slight amount of ozone.

Understanding the Trade-offs and Side Effects

Limited to Surface Applications

The greatest advantage of electron beams—their shallow penetration—is also their primary limitation. They are not suitable for treating deep-seated tumors or for sterilizing very dense or bulky products.

The effectiveness of the treatment is entirely dependent on delivering the correct dosage for the right amount of time to a target within the beam's limited range.

Common Medical Side Effects

When used in radiation therapy, patients may experience side effects. These typically include skin irritation such as redness and dryness, fatigue, and localized hair loss (alopecia).

Swelling (edema) in the treatment area can also occur. These side effects are generally temporary and improve over time after the treatment course is completed.

Impact on Healing

A notable side effect is the potential for delayed wound healing in the irradiated area. The amount of radiation delivered can cause wounds to heal more slowly than they normally would.

Making the Right Choice for Your Application

- If your primary focus is treating shallow tumors: Electron beam therapy offers unparalleled precision in targeting surface-level tissue while minimizing damage to deeper organs.

- If your primary focus is rapidly sterilizing medical devices: The speed, material safety, and lack of residual radioactivity make it a highly efficient and cost-effective choice.

- If you are dealing with deep targets or dense materials: You must consider alternative radiation sources, as the limited penetration of electron beams is a significant constraint.

Ultimately, electron beam radiation is a powerful and highly specialized tool for applications that demand precise, surface-level energy delivery.

Summary Table:

| Advantage | Key Benefit | Primary Application |

|---|---|---|

| Rapid Dose Falloff | Precise energy delivery; spares underlying tissues | Medical: Treating surface-level tumors |

| High-Speed Sterilization | Achieves sterility in seconds/minutes; protects material integrity | Industrial: Sterilizing medical devices & products |

| No Radioactive Source | Powered by electricity; can be switched off; minimal environmental impact | Operational Safety & Regulatory Compliance |

Optimize Your Sterilization or Treatment Process with KINTEK

Electron beam technology offers unparalleled precision and efficiency for surface-level applications. Whether you are developing medical therapies or require high-speed, material-safe sterilization for laboratory consumables, choosing the right equipment is critical.

KINTEK specializes in advanced lab equipment, including electron beam systems, designed to meet the rigorous demands of modern laboratories. Our solutions help you achieve superior results with enhanced safety and efficiency.

Contact our experts today to discuss how our electron beam technology can benefit your specific application and streamline your operations.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What is the temperature of autoclave in microbiology lab? Achieve Sterile Conditions with 121°C

- Why is autoclave temperature 134? Achieve Rapid Sterilization for Critical Instruments

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization

- What is the function of autoclave in tissue culture laboratory? Ensure Absolute Sterility for Successful Cell Growth

- What is the most commonly used autoclave? Discover the Industry Standard for Sterilization