At its core, metal pressing (or stamping) is a manufacturing process prized for its incredible speed, consistency, and cost-effectiveness at high volumes. It excels at converting flat metal sheets into finished parts through forming, punching, and shaping operations, making it a foundational technology for industries from automotive to electronics.

The choice between manufacturing processes is driven by project requirements. Metal pressing is the definitive solution for high-volume sheet metal components, while alternative processes like sintering are superior for creating complex, net-shape parts from powdered materials.

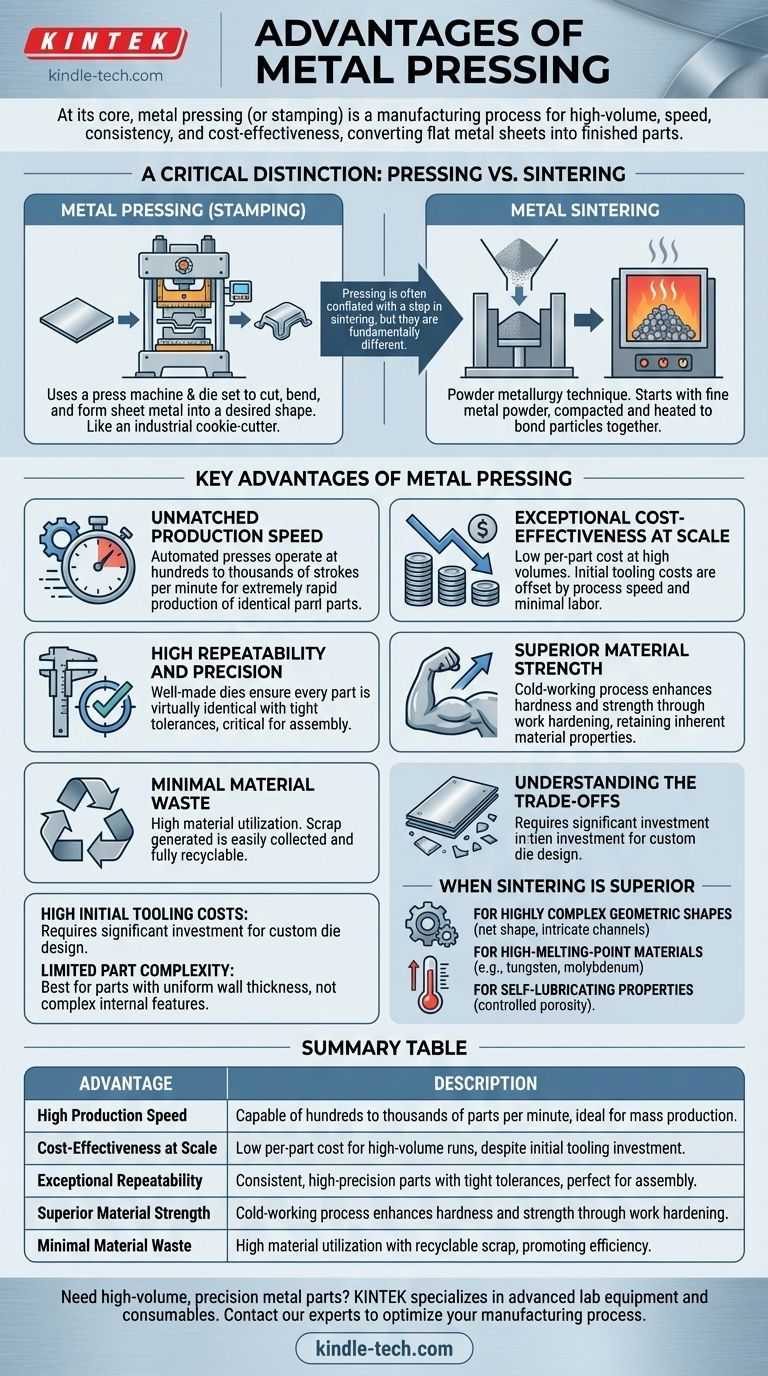

A Critical Distinction: Pressing vs. Sintering

Before detailing the advantages, it's crucial to clarify a common point of confusion. Metal pressing is often conflated with a step in the metal sintering process, but they are fundamentally different manufacturing methods.

What is Metal Pressing (Stamping)?

Metal pressing uses a press machine and a dedicated die set to cut, bend, and form a sheet of metal into a desired shape. Think of it as an extremely powerful and precise cookie-cutter and mold for metal. The final part is made from the original metal sheet.

What is Metal Sintering?

Metal sintering is a powder metallurgy technique. It starts with fine metal powder, which is compacted into a shape (this is the "pressing" step that causes confusion) and then heated to a temperature below its melting point, causing the particles to bond and fuse together.

Key Advantages of Metal Pressing

When your part design is compatible with sheet metal, pressing offers a powerful set of benefits, particularly as production volume increases.

Unmatched Production Speed

Automated stamping presses can operate at hundreds or even thousands of strokes per minute. This allows for the extremely rapid production of identical parts, far outpacing processes like CNC machining or 3D printing.

Exceptional Cost-Effectiveness at Scale

While the initial investment in tooling (the die) can be significant, the per-part cost becomes exceptionally low at high volumes. The speed of the process and high degree of automation minimize labor costs and production time for each unit.

High Repeatability and Precision

A well-made die ensures that every part produced is virtually identical to the last. This consistency is critical for applications requiring tight tolerances and seamless assembly, such as in automotive body panels or electronic enclosures.

Superior Material Strength

Metal pressing is a "cold-working" process. This deforms the metal's grain structure in a way that can increase its hardness and strength, a phenomenon known as work hardening. The part retains the inherent strength of the original metal sheet.

Minimal Material Waste

Modern pressing operations are designed for high material utilization. While some scrap is generated (e.g., from punched holes), it is easily collected and fully recyclable, making the process relatively efficient.

Understanding the Trade-offs of Metal Pressing

No process is perfect for every application. Objectivity requires acknowledging the limitations of pressing.

High Initial Tooling Costs

The primary drawback is the cost and lead time required to design and manufacture the custom die set. This upfront investment makes metal pressing uneconomical for low-volume production or prototyping.

Limited Part Complexity

Pressing is best suited for parts with a relatively uniform wall thickness. It cannot create the complex internal features, undercuts, or intricate geometries possible with casting, injection molding, or sintering.

Material Constraints

The process is limited to ductile metals that can be formed into sheets and shaped without fracturing. Brittle materials or those with very high strength can be difficult or impossible to press effectively.

When Sintering Becomes the Superior Choice

Understanding the advantages of pressing also means knowing when to choose an alternative. Sintering excels where pressing cannot.

For Highly Complex Geometric Shapes

Sintering can produce parts with intricate internal channels, varying densities, and complex 3D shapes in a single step, achieving a "net shape" that requires little to no secondary machining.

For High-Melting-Point Materials

Sintering works below the material's melting point, making it ideal for processing metals like tungsten or molybdenum, which are difficult to cast.

For Self-Lubricating Properties

The sintering process can be controlled to create parts with a specific level of porosity. These pores can be impregnated with lubricants, resulting in self-lubricating bearings and gears.

Making the Right Choice for Your Project

Selecting the correct process requires aligning its strengths with your primary goal.

- If your primary focus is mass-producing simple to moderately complex parts from sheet metal: Metal pressing offers the lowest per-part cost and highest production speed.

- If your primary focus is creating intricate, net-shape parts or using exotic powdered materials: Metal sintering provides design freedom and material capabilities that pressing cannot match.

- If your primary focus is low-volume production or prototyping: The high tooling cost of pressing makes other methods like CNC machining or 3D printing more viable.

Ultimately, understanding the fundamental difference between forming a sheet and fusing a powder is the key to selecting the most effective manufacturing process for your needs.

Summary Table:

| Advantage | Description |

|---|---|

| High Production Speed | Capable of hundreds to thousands of parts per minute, ideal for mass production. |

| Cost-Effectiveness at Scale | Low per-part cost for high-volume runs, despite initial tooling investment. |

| Exceptional Repeatability | Consistent, high-precision parts with tight tolerances, perfect for assembly. |

| Superior Material Strength | Cold-working process enhances hardness and strength through work hardening. |

| Minimal Material Waste | High material utilization with recyclable scrap, promoting efficiency. |

Need high-volume, precision metal parts for your lab or production line? KINTEK specializes in providing advanced lab equipment and consumables, including solutions for material testing and processing. Whether you're exploring metal pressing for prototyping or scaling up production, our expertise can help you optimize your manufacturing process. Contact our experts today to discuss your project requirements and discover how KINTEK can support your laboratory and production needs with reliable, efficient solutions.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Which oil is used in hydraulic press machine? Choose the Right Fluid for Maximum Performance

- Can hydraulic systems that run too hot or too cold cause severe problems over time? Yes, and here's how to prevent it.

- Why is a uniaxial hydraulic press used for LLZTO powder? Achieving High Green Density for Ceramic Success

- Why is a laboratory hydraulic press required before SPS? Ensure Perfect Solid-State Battery Layers

- What is a 100 ton hydraulic press? Harnessing Immense Force for Industrial Applications

- What is the danger of press machine? Unforgiving Power That Demands Absolute Safety

- What is the function of laboratory hydraulic presses in leaching residue prep? Master SEM Sample Precision

- What happens when hydraulic fluid gets too hot? The Vicious Cycle of Wear and System Failure