The primary advantages of press moulding are its low initial tooling costs, its ability to produce exceptionally strong parts from a wide range of materials, and its minimal material waste. This makes it a highly effective method for producing large, flat, or moderately curved components, particularly from composite or thermoset materials that are difficult to process with other methods.

Press moulding is not a universal solution; its true value lies in its cost-effectiveness for low-to-medium production volumes and its unique capability to handle high-strength, fiber-reinforced composites that are unsuitable for other processes like injection moulding.

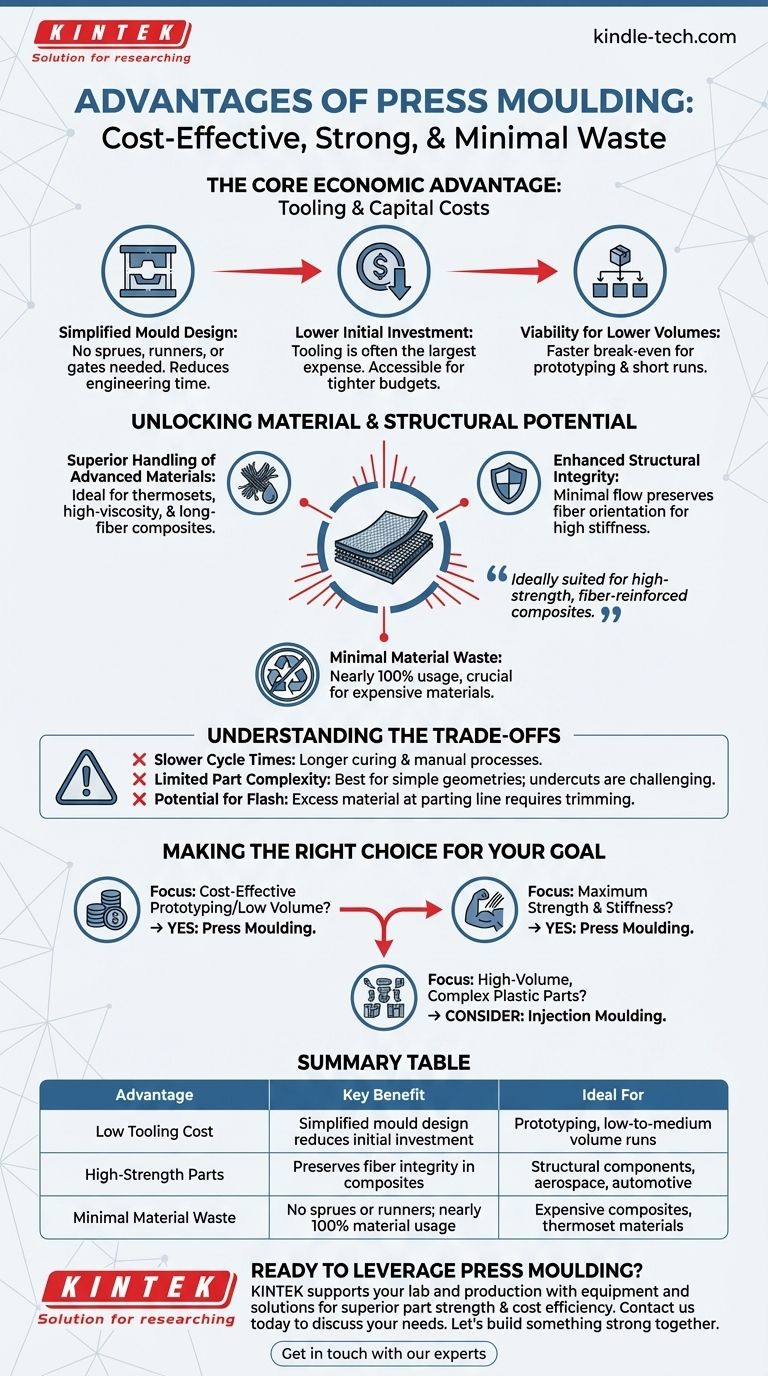

The Core Economic Advantage: Tooling and Capital Costs

For many projects, the decision to use press moulding begins with a simple cost-benefit analysis. The process holds a distinct economic edge in specific scenarios due to its inherent simplicity.

Simplified Mould Design

The moulds used in press moulding are significantly less complex than those required for processes like injection moulding. They do not require an intricate system of sprues, runners, and gates to distribute the material.

The mould is essentially a two-part cavity, which dramatically reduces the design, engineering, and machining time required to create the tool.

Lower Initial Investment

This simplified mould design translates directly into lower upfront costs. Tooling is often the single largest capital expense when starting a new production run, and the lower cost of press moulding tools makes the process accessible for projects with tighter budgets.

Viability for Lower Volumes

Because the initial investment is lower, press moulding is an economically viable option for prototyping, short runs, and low-to-medium volume production. The break-even point is reached much faster compared to high-volume methods that require a massive number of parts to recoup expensive tooling costs.

Unlocking Material and Structural Potential

Beyond cost, press moulding offers unique engineering benefits, especially when working with advanced materials where part strength is a critical requirement.

Superior Handling of Advanced Materials

Press moulding excels at shaping materials that are difficult or impossible to use in other processes. This includes thermoset plastics, high-viscosity materials, and long-fiber composites (like carbon fiber or glass fiber).

These materials do not flow easily through the narrow channels of an injection mould. Placing a pre-measured charge directly into the cavity bypasses this limitation.

Enhanced Structural Integrity

In press moulding, the material experiences very little flow as it fills the mould. This is crucial for fiber-reinforced composites, as it minimizes fiber degradation and undesirable orientation, preserving the material's inherent strength.

The result is parts with excellent structural integrity, high stiffness, and low internal stress, making them ideal for high-performance applications.

Minimal Material Waste

Since there are no sprues or runners, nearly all the material placed in the mould becomes part of the final product. This is a significant advantage, especially when working with expensive composite materials or thermosets, which cannot be melted down and reused like thermoplastics.

Understanding the Trade-offs

No manufacturing process is perfect. To make an informed decision, you must weigh the advantages against the inherent limitations of press moulding.

Slower Cycle Times

Press moulding is generally a slower process. The cycle involves manually or robotically placing the charge, a longer curing time under heat and pressure, and manual part removal. This makes it less suitable for high-volume, high-speed production where seconds per part matter.

Limited Part Complexity

The process is best suited for parts with relatively simple geometries. Creating undercuts, intricate features, or very thin walls can be challenging. The direct vertical pressure does not lend itself to filling complex, non-linear voids as effectively as high-pressure injection moulding.

Potential for Flash

It is common for a small amount of excess material, known as "flash," to be squeezed out at the parting line of the mould. This flash must be removed in a secondary trimming operation, adding a step to the production process and potentially affecting final part tolerances.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on your project's specific priorities.

- If your primary focus is cost-effective prototyping or low-volume production: Press moulding is an excellent choice due to its low initial tooling investment.

- If your primary focus is maximum strength and stiffness using fiber composites: Press moulding's ability to handle long-fiber materials without degrading them is its key advantage.

- If your primary focus is high-volume production of complex plastic parts: You should likely consider injection moulding, as its speed and ability to create intricate geometries will outweigh its higher tooling cost.

Understanding these core principles allows you to leverage press moulding as a powerful and economical tool for the right applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Tooling Cost | Simplified mould design reduces initial investment | Prototyping, low-to-medium volume runs |

| High-Strength Parts | Preserves fiber integrity in composites | Structural components, aerospace, automotive |

| Minimal Material Waste | No sprues or runners; nearly 100% material usage | Expensive composites, thermoset materials |

| Material Versatility | Handles high-viscosity and long-fiber materials | Applications requiring specific material properties |

Ready to leverage press moulding for your project?

At KINTEK, we specialize in providing the lab equipment and consumables needed to support advanced manufacturing processes like press moulding. Whether you're prototyping with composites or moving into low-volume production, our solutions help you achieve superior part strength and cost efficiency.

Contact us today to discuss how we can support your laboratory and production needs. Let's build something strong together.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy