In essence, press working operations are a cornerstone of modern manufacturing due to their unparalleled speed, repeatability, and cost-effectiveness in high-volume scenarios. This process uses a die and punch to cut or form sheet metal into a desired shape, enabling the rapid creation of identical parts with minimal human intervention and excellent material efficiency.

The fundamental advantage of press working is its ability to trade a high initial investment in tooling for an extremely low cost per part. This makes it the undisputed champion for mass production, but a poor choice for prototyping or low-volume runs.

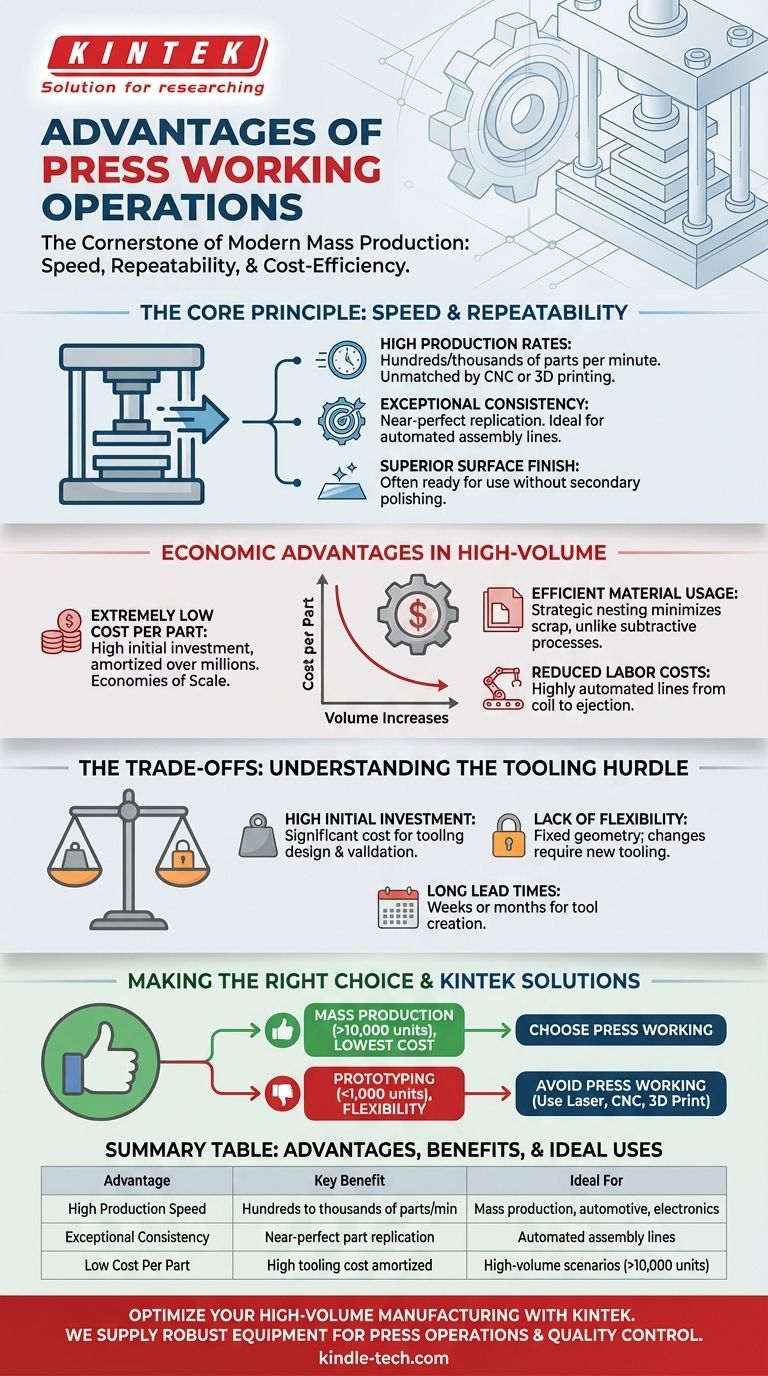

The Core Principle: Speed and Repeatability

Press working, also known as stamping, is built on a simple mechanical principle: applying immense force to a tool (a die) to shape material. This foundation gives it several key operational advantages.

High Production Rates

The cycle time of a press is incredibly short, often measured in fractions of a second. A single press can perform hundreds or even thousands of strokes per minute.

This speed allows for the production of millions of parts in a relatively short period, a rate that is simply unachievable with processes like CNC machining or 3D printing.

Exceptional Consistency and Accuracy

The precision of the final part is dictated by the precision of the die set. Once the die is manufactured and qualified, every part it produces will be a near-perfect replica of the last.

This high degree of repeatability is critical for industries like automotive and electronics, where components must fit together perfectly in automated assembly lines.

Superior Surface Finish

Parts emerging from a press operation often have a smooth, clean surface finish that may not require secondary finishing operations like polishing or grinding. This further reduces the overall production time and cost.

Economic Advantages in High-Volume Scenarios

The true power of press working is unlocked when production volumes are high enough to amortize the initial cost of the tooling.

Extremely Low Cost Per Part

While the die set can be expensive to design and build, the marginal cost of producing each subsequent part is incredibly low. It primarily consists of the raw material cost and the energy to run the press.

This is a classic example of economies of scale. As production volume increases, the cost per part plummets.

Efficient Material Usage

Press working is a highly efficient process in terms of material consumption. Parts can be strategically laid out (nested) on a sheet or coil of metal to minimize scrap.

This contrasts sharply with subtractive processes like machining, where a significant portion of the initial raw material can be turned into waste chips.

Reduced Labor Costs

Modern press lines are highly automated. Material can be fed automatically from coils, and finished parts can be ejected and conveyed without direct human labor, drastically reducing the labor cost embedded in each component.

Understanding the Trade-offs: The Tooling Hurdle

No manufacturing process is without its limitations. The primary disadvantage of press working is directly tied to its greatest strength: the tooling.

High Initial Investment

The design, manufacture, and validation of a high-quality, production-ready die set is a significant upfront expense. This investment can range from thousands to hundreds of thousands of dollars, depending on the complexity of the part.

This cost barrier makes press working completely uneconomical for prototypes or small production runs.

Lack of Flexibility

A die is built to produce one specific part geometry. If the design of the part needs to change, the die must be modified or, more often, completely remade.

This inflexibility is a major drawback in markets where designs iterate quickly. Once you commit to a die, you are locked into that design for a significant production quantity.

Long Lead Times for Tooling

The process of creating the toolset can take weeks or even months. This means the time from final design approval to the first production part is much longer than for processes that do not require hard tooling.

Making the Right Choice for Your Project

The decision to use press working hinges almost entirely on your expected production volume and design stability.

- If your primary focus is mass production (>10,000 units) and the lowest per-part cost: Press working is almost certainly the correct choice, provided your design is finalized and you can absorb the tooling investment.

- If your primary focus is prototyping or low-volume runs (<1,000 units): Avoid press working entirely. Processes like laser cutting, CNC punching, or even 3D printing offer far more financial and operational sense.

- If your primary focus is design flexibility and iteration: The high cost and inflexibility of tooling make press working unsuitable for projects with evolving designs or uncertain market demand.

By understanding the relationship between initial investment and per-part cost, you can confidently determine if press working is the right tool to achieve your manufacturing goals.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High Production Speed | Hundreds to thousands of parts per minute | Mass production, automotive, electronics |

| Exceptional Consistency | Near-perfect part replication from precision dies | Automated assembly lines, quality-critical industries |

| Low Cost Per Part | High initial tooling cost amortized over large volumes | High-volume scenarios (>10,000 units) |

| Efficient Material Usage | Minimal scrap through strategic nesting on sheet metal | Cost-sensitive manufacturing |

| Reduced Labor Costs | Highly automated process from coil feeding to part ejection | Streamlined, high-volume operations |

Ready to Optimize Your High-Volume Manufacturing?

Press working is the undisputed champion for mass production, but success hinges on precision tooling and reliable equipment. At KINTEK, we specialize in supplying the robust lab and production equipment needed to support your press operations, from material testing to quality control.

Our expertise in serving laboratory and manufacturing needs ensures you have the right tools to achieve exceptional consistency and cost-efficiency. Let's discuss how our solutions can enhance your production line.

Contact KINTEL today for a personalized consultation and discover the right equipment for your mass production goals.

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Anti-Cracking Press Mold for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the purpose of using a laboratory hydraulic press for pre-pressure? Enhance Sintering Precision & Density

- What is a hydraulic press machine used for? From industrial forming to lab sample prep

- How does a high-pressure laboratory hydraulic press ensure the molding quality of MgO-C refractory green bodies?

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- What role does a laboratory hydraulic press play in platinum recovery research? Enhancing Sample Precision

- What are the advantages of hydraulic press over mechanical press? Flexibility, Control & Cost Savings

- What is the primary purpose of using a laboratory hydraulic press for pre-pressing? Achieve Optimal Sintering Results

- What are 3 uses of a hydraulic press? Discover Force Multiplication for Industry & Science