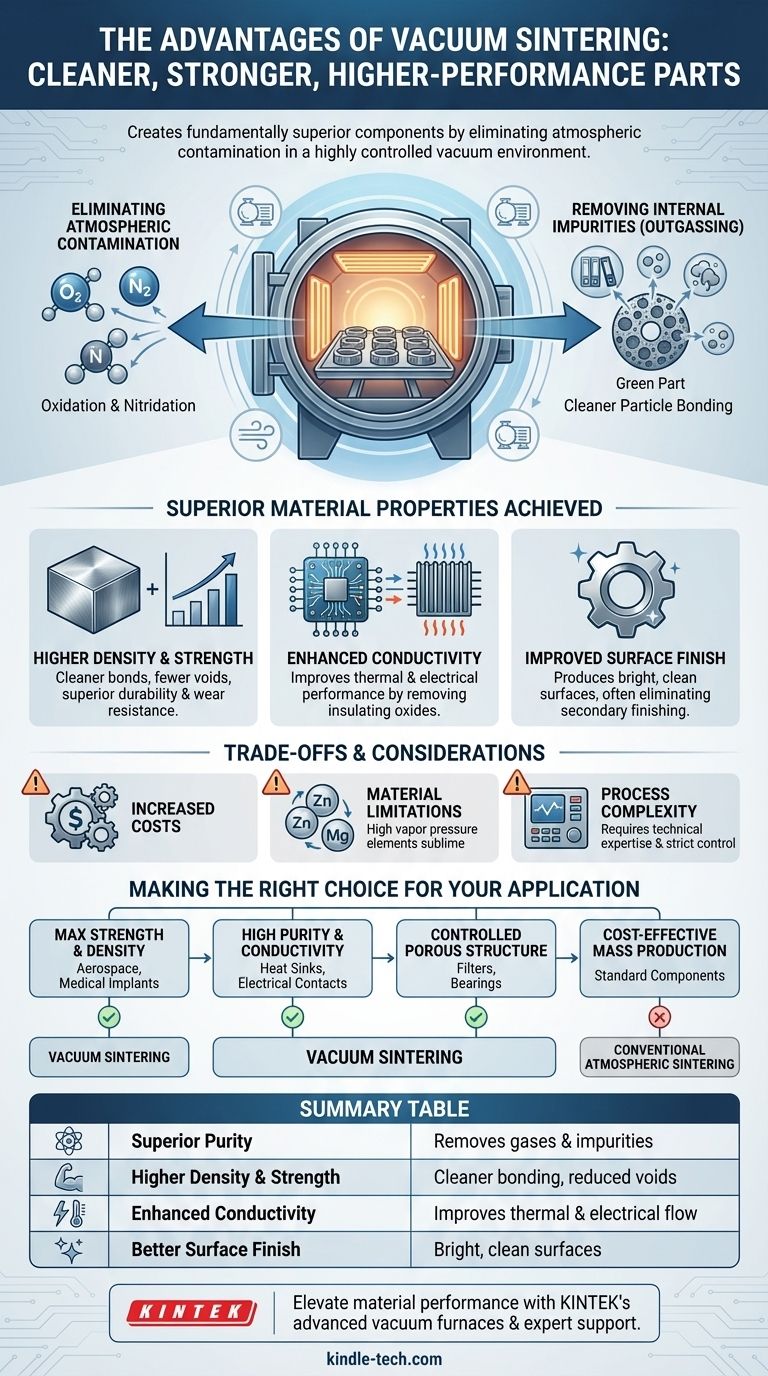

In short, vacuum sintering creates fundamentally cleaner, stronger, and higher-performance parts. By performing the heating process in a vacuum, it eliminates atmospheric gases that cause contamination, such as oxygen and nitrogen. This prevents the formation of undesirable oxides and nitrides, allowing material particles to bond more effectively and result in a final component with superior density, purity, and mechanical properties.

While standard sintering strengthens powdered materials, vacuum sintering elevates the process by creating a highly controlled environment. This prevents unwanted chemical reactions, resulting in superior purity and material properties that are often impossible to achieve in a conventional atmosphere.

The Fundamental Advantage: A Controlled Environment

The primary benefit of vacuum sintering isn't a single outcome but the pristine environment it creates. Nearly all other advantages stem from this foundational principle.

Eliminating Atmospheric Contamination

The most significant role of the vacuum is to remove reactive gases like oxygen, nitrogen, and water vapor from the furnace. This directly prevents harmful chemical reactions like oxidation and nitridation, which can form brittle, insulating layers on the surface of the material particles.

Without these oxide layers, the particles have cleaner surfaces, allowing them to bond more directly and completely during heating.

Removing Internal Impurities (Outgassing)

The initial "green" part, formed by compacting powder, contains more than just the base material. It also includes binders, lubricants used during pressing, and trapped air in the pores.

A vacuum environment actively pulls these volatile substances out of the component before the final sintering temperature is reached. This process, known as outgassing, results in a significantly purer final material.

How Control Translates to Superior Material Properties

The clean, controlled environment of vacuum sintering has a direct and measurable impact on the final component's performance.

Achieving Higher Density and Strength

By removing trapped gases from pores and preventing oxide films from interfering with bonding, vacuum sintering allows for more effective pore closure. This leads to parts with higher density and significantly reduced internal voids.

Fewer voids and cleaner bonds between material grains result in superior mechanical strength, durability, and wear resistance, reducing the likelihood of component failure in demanding applications.

Enhancing Thermal and Electrical Conductivity

Impurities and oxide layers act as insulators, impeding the flow of electrons and heat. By producing a purer, denser material, vacuum sintering creates a clearer path for this energy transfer.

This makes it the preferred method for components where high thermal or electrical conductivity is a critical design requirement.

Improving Surface Finish

Because oxidation is prevented, parts emerge from a vacuum furnace with a clean, bright surface. This can often reduce or completely eliminate the need for secondary finishing processes, saving time and cost.

Understanding the Trade-offs and Considerations

While powerful, vacuum sintering is not the default choice for every application. Understanding its limitations is key to making an informed decision.

Increased Equipment and Operational Costs

Vacuum furnaces are inherently more complex and expensive than their atmospheric counterparts. The process also requires additional time for pumping the chamber down to the required vacuum level, which can lead to longer overall cycle times.

Material Limitations

Not all materials are suitable for vacuum sintering. Elements with a high vapor pressure (like zinc, manganese, or magnesium) can effectively "boil off" or sublimate at high temperatures in a vacuum, altering the material's final composition.

Process Complexity

Operating a vacuum furnace requires more technical expertise and stricter process control. Maintaining vacuum integrity, monitoring outgassing, and managing precise temperature profiles demands a higher level of operational skill.

Making the Right Choice for Your Application

Choosing vacuum sintering depends entirely on the required performance and cost constraints of your component.

- If your primary focus is maximum strength, fatigue resistance, and density: Vacuum sintering is superior for creating mission-critical parts, such as those in aerospace or medical implants, by eliminating voids and ensuring clean grain boundaries.

- If your primary focus is high purity and electrical/thermal performance: The clean environment of a vacuum is non-negotiable for applications like high-performance heat sinks or electrical contacts where insulating oxides cannot be tolerated.

- If your primary focus is a controlled porous structure: Vacuum sintering provides the precision to clean particle surfaces for strong bonding while carefully preserving an engineered pore network, ideal for filters or self-lubricating bearings.

- If your primary focus is cost-effective mass production with good properties: Conventional atmospheric sintering may be sufficient and more economical for components where the absolute highest performance is not the primary driver.

Ultimately, leveraging a vacuum transforms sintering from a simple strengthening process into a precision engineering tool for advanced materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Purity | Removes atmospheric gases and internal impurities (outgassing). |

| Higher Density & Strength | Enables cleaner particle bonding, reducing voids and increasing durability. |

| Enhanced Conductivity | Improves thermal and electrical performance by eliminating insulating oxides. |

| Better Surface Finish | Produces bright, clean surfaces, often eliminating secondary finishing. |

Ready to elevate your material performance with precision vacuum sintering? KINTEK specializes in advanced lab equipment and consumables, providing the reliable vacuum furnaces and expert support needed to achieve superior part purity, strength, and conductivity for your most demanding applications in aerospace, medical, and electronics. Contact our experts today to discuss your specific sintering requirements!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Which material is suitable for hardening? The Critical Role of Carbon Content in Steel Selection

- What are the advantages of using a vacuum brazing furnace for TLP bonding? Achieve Superior Joint Integrity

- What precautions should be taken during heat treatment? Essential Safety and Quality Control Measures

- How are pyrolysis reactors heated? Choosing the Right Method for Your Process

- How long does a vacuum heat treatment cycle take? It Depends on Your Material and Part Size

- How is a vacuum drying oven utilized in the preparation of polymer-inorganic composite solid electrolytes?

- Does hardening steel change dimensions? Mastering the Forces of Thermal and Metallurgical Change

- What role does a high-temperature vacuum annealing furnace play in Ti-Cr-Al-Nb-V alloys? Optimize Phase Transformation