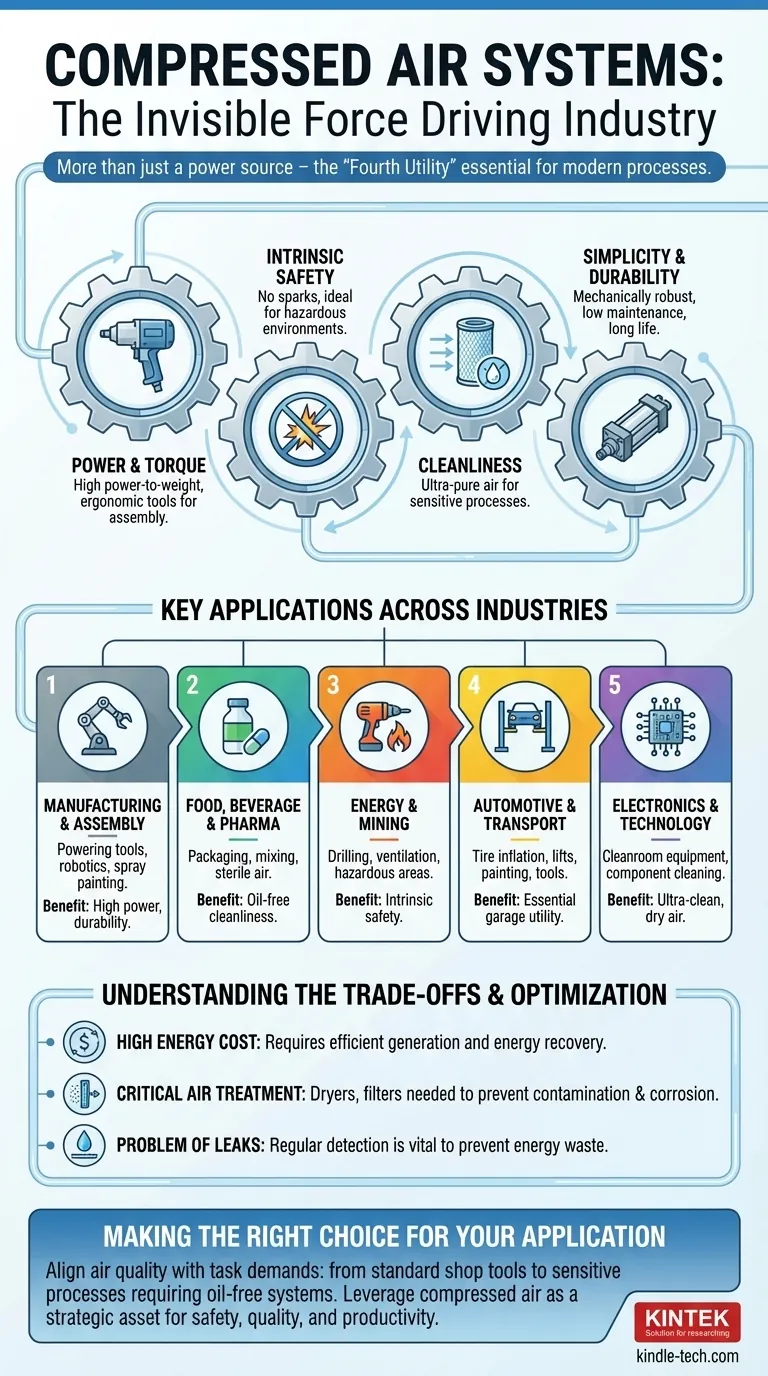

Beyond simply powering tools, compressed air is a fundamental utility that drives a vast range of industrial, commercial, and technical processes. Its applications span from heavy manufacturing and mining to sensitive environments like food packaging, pharmaceutical production, and electronics fabrication. This versatility makes it an indispensable, albeit often invisible, force in the modern world.

The core reason for its widespread use is that compressed air is more than just a power source; it's a uniquely adaptable medium. Its value comes from its intrinsic safety, controllability, and potential for extreme cleanliness, establishing it as the "fourth utility" alongside electricity, water, and natural gas.

Why Compressed Air is the "Fourth Utility"

Understanding the fundamental properties of compressed air explains why it's chosen for such a diverse set of tasks. It offers unique advantages where other power sources fall short.

Power and Torque in a Compact Form

Pneumatic tools are known for their exceptional power-to-weight ratio. They can deliver high torque and rotational speed from a simple, durable air motor, making them lighter and more ergonomic than their electric counterparts.

This is critical for assembly lines and maintenance work where operators use tools for extended periods.

Intrinsic Safety in Hazardous Environments

Perhaps the most critical advantage is safety. Air-powered tools and actuators have no internal electrical components at the point of use, eliminating the risk of sparks.

This makes them the default choice in explosive or flammable atmospheres, such as paint booths, oil refineries, grain elevators, and underground mines.

Cleanliness for Sensitive Processes

Air can be treated to meet extremely high purity standards. Through a process of filtration and drying, compressed air can be made free of oil, water vapor, and particulate matter.

This "process air" is essential in industries like food and beverage for packaging, mixing, and conveying, as well as in electronics manufacturing for operating sensitive cleanroom equipment.

Simplicity and Durability

Pneumatic systems are mechanically robust. They can withstand harsh conditions, including dust, high temperatures, and moisture, that would damage or destroy sensitive electronic equipment.

Their relative simplicity also makes them easier to maintain and gives them a long operational life with minimal service.

Key Applications Across Industries

While the principles are universal, the specific applications highlight the versatility of compressed air across different sectors.

Manufacturing and Assembly

This is the most common application space. Air is used to power everything from impact wrenches and grinders to robotic arms, clamps, and positioners on automated assembly lines. It's also used for sandblasting and spray painting surfaces.

Food, Beverage, and Pharmaceuticals

Here, cleanliness is paramount. Oil-free compressed air is used to clean and dry containers, sort and move products on conveyor lines, mix ingredients, and provide the sterile air needed for packaging.

Energy and Mining

Safety is the driving factor in these environments. Compressed air powers drilling equipment, ventilation systems, and a wide variety of tools where an electrical spark could be catastrophic.

Automotive and Transportation

From the local garage to the factory floor, compressed air is essential. It's used for tire inflation, operating vehicle lifts, powering painting and finishing tools, and driving the pneumatic tools used in vehicle assembly and repair.

Electronics and Technology

In high-tech manufacturing, even microscopic dust particles can ruin a product. Ultra-clean, dry compressed air is used to clean delicate components, operate precise pneumatic controls in cleanrooms, and power pick-and-place machines for circuit boards.

Understanding the Trade-offs

Despite its advantages, compressed air is not a "free" resource. Understanding its limitations is key to using it effectively.

The High Cost of Energy

Generating compressed air is an energy-intensive process. It is one of the most expensive utilities in a plant, and significant energy is lost as heat during compression.

The Critical Need for Air Treatment

Atmospheric air contains water vapor, oil, and dust. If left untreated, these contaminants will corrode pipes, damage pneumatic tools, and contaminate end products.

Effective systems require dryers, filters, and sometimes lubricators, which add to the initial cost and ongoing maintenance of the system.

The Problem of Leaks

Leaks are the single biggest source of wasted energy in a compressed air system. A small, inaudible leak can waste thousands of dollars in electricity costs over a year. A regular leak detection and repair program is essential.

Making the Right Choice for Your Application

Selecting the right type of compressed air system depends entirely on its intended use. The quality of the air must match the demands of the task.

- If your primary focus is powering tools in a general workshop: A standard, oil-lubricated system is often sufficient, prioritizing durability and power delivery.

- If your primary focus is a sensitive process like food packaging or spray finishing: You must use an oil-free compressor and a multi-stage air treatment system to guarantee air purity.

- If your primary focus is operating in a hazardous environment: Pneumatic tools and controls are the safest and most reliable choice, justifying the investment in a robust compressed air infrastructure.

By understanding its core properties and applications, you can leverage compressed air not just as a utility, but as a strategic asset for safety, quality, and productivity.

Summary Table:

| Application Area | Key Use Case | Primary Benefit |

|---|---|---|

| Manufacturing & Assembly | Powering tools, robotics, spray painting | High power-to-weight ratio, durability |

| Food, Beverage & Pharma | Packaging, mixing, sterile air processes | Oil-free cleanliness, contamination control |

| Energy & Mining | Drilling, ventilation, hazardous area tools | Intrinsic safety (no sparks) |

| Electronics & Tech | Cleanroom equipment, component cleaning | Ultra-clean, dry air for sensitive processes |

Need a reliable compressed air solution for your lab or production facility? KINTEK specializes in high-quality lab equipment and consumables, including air treatment systems that ensure the purity and reliability your processes demand. Whether you require oil-free compressors for sensitive applications or robust systems for industrial use, our expertise can help you optimize for safety, efficiency, and product quality. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is a Laboratory Freeze Dryer and what is its primary function? Achieve Perfect Preservation of Sensitive Materials

- What is the critical temperature in freeze drying? The Key to Successful Lyophilization

- In which fields is the laboratory freeze dryer commonly used? Essential for Biopharma, Food Science & Research

- How does laboratory freeze drying work to preserve biological products? The Ultimate Guide to Lyophilization

- What are the disadvantages of using a Laboratory Freeze Dryer? High Costs, Long Times, and Technical Demands