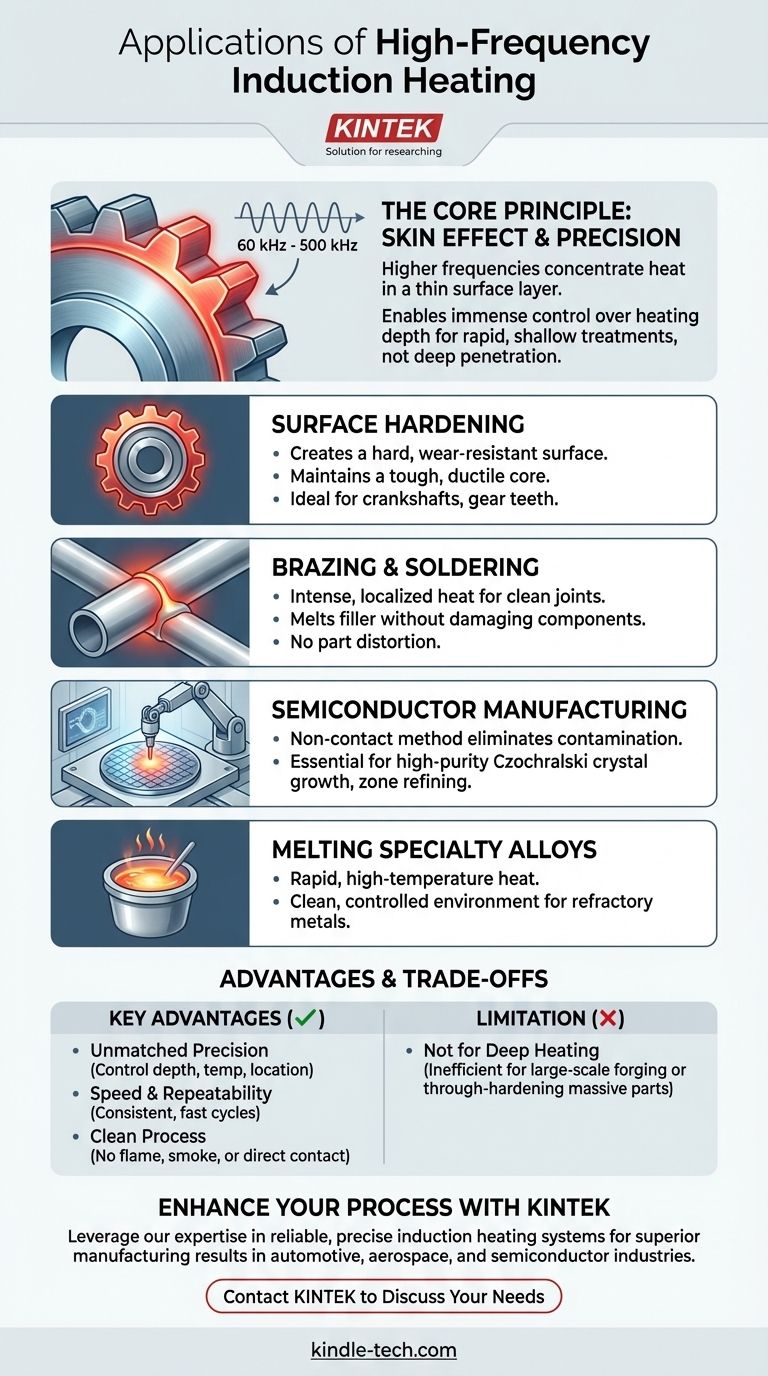

In short, high-frequency induction heating is a precision tool used for applications requiring rapid, controlled heating on the surface of a material. Its most common uses are in surface hardening metals, brazing or soldering components, and in high-purity processes like semiconductor manufacturing where cleanliness and precision are critical. The technology excels where the goal is to alter the surface of a part without affecting its core.

The core principle is simple: higher frequencies concentrate heat in a very thin layer on the material's surface. This "skin effect" provides immense control over heating depth, making it the ideal choice for surface-specific treatments rather than heating an entire object through.

The Core Principle: Why High Frequency Excels

To understand the applications, you must first understand the physics. Induction heating works by creating an electromagnetic field that induces an electrical current inside a conductive material, generating heat directly within the part itself. The frequency of this field is the most important variable.

Understanding the "Skin Effect"

At higher frequencies, typically defined as 60 kHz to 500 kHz, the induced electrical current naturally flows in a thin layer near the surface of the workpiece. This phenomenon is known as the skin effect.

Think of it like skipping a stone across water. A fast, high-frequency spin keeps the stone right at the surface. A slow, low-frequency toss would cause it to sink deep. In the same way, high-frequency current doesn't penetrate deeply into the material.

The Benefit of Shallow, Rapid Heating

This shallow heating depth is not a limitation; it is the technology's primary strength. By concentrating energy on the surface, the process becomes incredibly fast and efficient.

You can heat the surface of a steel gear tooth to its hardening temperature in seconds, while the core of the tooth remains cool and ductile. This level of control is impossible with conventional flames or furnaces.

Key Industrial Applications

The principle of rapid, shallow heating unlocks a range of specialized industrial uses where precision is paramount.

Surface Hardening

This is the classic application. Processes like case hardening a crankshaft or the teeth on a gear require a very hard, wear-resistant surface while maintaining a softer, tougher core that can absorb shock. High-frequency induction is perfect for creating this dual characteristic with pinpoint accuracy.

Brazing and Soldering

When joining two metal components, you need to melt a filler material without melting the components themselves. High-frequency induction provides intense, localized heat directly at the joint, ensuring a quick and clean bond without distorting or damaging the rest of the assembly.

Semiconductor Manufacturing

In processes like Czochralski crystal growth and zone refining, absolute purity is essential. Induction heating is a non-contact method; no flame or heating element ever touches the material. This completely eliminates contamination, making it a cornerstone of the semiconductor industry.

Melting High-Temperature Metals

While lower frequencies are often used for bulk melting, high-frequency systems are used to melt refractory metals or specialty alloys that demand very high temperatures and a clean environment. The heat is generated quickly and contained precisely within the crucible.

Understanding the Advantages and Trade-offs

No technology is a universal solution. Understanding where high-frequency induction shines—and where it doesn't—is key to making an informed decision.

Key Advantage: Unmatched Precision

The primary benefit is control. You can precisely dictate the depth, temperature, and location of the heat. This reduces energy waste and minimizes the risk of warping or other heat-related defects in the material.

Key Advantage: Speed and Repeatability

Because heat is generated directly within the part, the process is extremely fast. Once a cycle is programmed, it can be repeated thousands of times with virtually no variation, ensuring consistent quality in mass production.

Key Advantage: A Clean Process

Induction is a clean, non-polluting process. There is no flame, no smoke, and no direct contact with the workpiece, which is critical for medical, aerospace, and semiconductor applications where material purity is non-negotiable.

Important Limitation: Not for Deep Heating

The skin effect makes high-frequency induction a poor choice for applications that require heating a large part all the way through to its core. For tasks like large-scale forging or through-hardening massive components, a lower frequency system or a conventional furnace is more effective and efficient.

Making the Right Choice for Your Goal

To apply this knowledge, match the technology's strengths to your specific industrial objective.

- If your primary focus is surface treatment: High-frequency induction is the superior choice for hardening, tempering, or coating applications due to its precise depth control.

- If your primary focus is joining components: The speed and localized heating of high frequency are ideal for brazing and soldering, preventing damage to the surrounding assembly.

- If your primary focus is purity and cleanliness: The non-contact nature of induction heating makes it essential for semiconductor, medical, and specialty alloy manufacturing.

- If your primary focus is bulk or through-heating: You should investigate lower-frequency induction systems or traditional furnace technologies better suited for deep heat penetration.

Ultimately, mastering high-frequency induction heating comes from understanding and leveraging its ability to place heat exactly where you need it, and nowhere else.

Summary Table:

| Application | Key Benefit |

|---|---|

| Surface Hardening | Creates a hard, wear-resistant surface while maintaining a tough core. |

| Brazing & Soldering | Provides intense, localized heat for clean joints without part distortion. |

| Semiconductor Manufacturing | Ensures a non-contact, contamination-free process for high-purity materials. |

| Melting Specialty Alloys | Delivers rapid, high-temperature heat in a controlled, clean environment. |

Ready to enhance your manufacturing process with precise, high-frequency induction heating?

At KINTEK, we specialize in advanced lab and industrial equipment, including induction heating systems. Our solutions are designed to deliver the speed, cleanliness, and pinpoint accuracy your applications demand, whether you're hardening components, brazing assemblies, or working with high-purity materials.

We help our customers in industries like automotive, aerospace, and semiconductor manufacturing achieve superior results through reliable and efficient technology.

Contact KINTEK today to discuss your specific needs and discover how our expertise in lab equipment and consumables can bring precision and efficiency to your operation.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What are the advantages of using vacuum hot pressing for SiC/Al composites? Achieve Superior Microstructural Control

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?