At their core, high-temperature materials are the foundational technology for any industry operating at extreme thermal conditions. They are essential in aerospace for jet engines and spacecraft, in power generation for gas turbines and nuclear reactors, and in industrial processes like metal smelting and glass manufacturing, where conventional materials would rapidly degrade and fail.

The true value of a high-temperature material is not just its ability to resist melting; it is the preservation of its structural integrity, mechanical strength, and chemical stability under extreme thermal stress that makes modern, high-performance engineering possible.

The Core Challenge: Why Standard Materials Fail

Before examining the applications, it's critical to understand the problems high-temperature materials solve. As temperatures rise, conventional metals and polymers begin to break down in predictable ways.

Loss of Mechanical Strength

At elevated temperatures, the atomic bonds within metals weaken. This causes them to soften, lose their stiffness, and become susceptible to a slow, permanent deformation under load, a phenomenon known as creep.

Accelerated Oxidation and Corrosion

Heat acts as a powerful catalyst for chemical reactions. For most metals, this means a drastically increased rate of oxidation (rusting) and corrosion, which eats away at the material and compromises its structural integrity.

Phase Instability

The internal crystal structure of a material can change when exposed to sufficient heat. These phase changes can lead to brittleness, warping, or a complete loss of the properties for which the material was originally chosen.

Key Applications in Aerospace and Defense

The aerospace industry is arguably the primary driver of high-temperature material science. The goals of flying faster, higher, and more efficiently are directly limited by material temperature thresholds.

Jet Engine Components

The hottest sections of a modern jet engine—the combustor, turbine blades, and exhaust nozzle—operate at temperatures well above the melting point of steel. Nickel-based superalloys are used here because they retain incredible strength at these temperatures.

Thermal Barrier Coatings (TBCs)

To push performance even further, engine components are often coated with a thin layer of advanced ceramics. These TBCs act as a thermal insulator, protecting the underlying superalloy from the most extreme heat and allowing the engine to run hotter and more efficiently.

Spacecraft and Hypersonics

Atmospheric re-entry generates immense heat from air friction. Spacecraft heat shields rely on materials like carbon-carbon composites or specialized ceramic tiles that can withstand and dissipate these extreme thermal loads to protect the vehicle and its occupants.

Power Generation and the Energy Sector

Efficiency in power generation is directly tied to operating temperature. The hotter a turbine can run, the more energy it can extract from its fuel source.

Gas and Steam Turbine Blades

Similar to jet engines, power-generating gas turbines use superalloys and thermal barrier coatings for their blades and vanes. This allows for higher combustion temperatures, leading to greater efficiency and lower emissions for a given power output.

Nuclear Reactor Components

Materials within a nuclear reactor core must withstand not only high temperatures but also intense radiation. Zirconium alloys and specialized stainless steels are chosen for their ability to maintain structural stability in this uniquely harsh environment.

Concentrated Solar Power

In solar thermal plants, materials used in the central receiver must absorb intense focused sunlight and transfer that heat to a working fluid without degrading. High-temperature alloys and ceramics are crucial for this application's longevity and efficiency.

Industrial and Manufacturing Processes

Many fundamental industrial processes require the containment and application of extreme heat, making high-temperature materials a necessity.

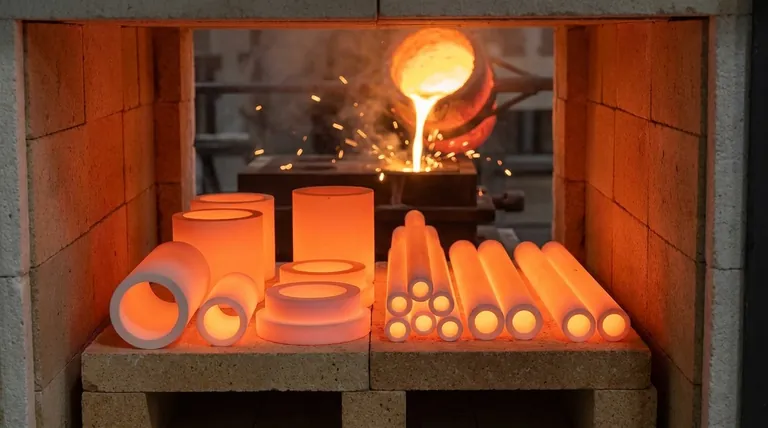

Furnaces, Kilns, and Reactors

The linings of industrial furnaces for steelmaking, glass manufacturing, and cement production are built from refractory ceramics. These materials, like alumina and zirconia, are chemically stable and act as excellent thermal insulators at very high temperatures.

High-Temperature Tooling

Tools used for processes like forging, extrusion, and die-casting must maintain their shape and hardness while in contact with molten or white-hot metal. Tool steels and specialized alloys are designed specifically for this purpose.

Advanced Sensors

To monitor and control high-temperature processes, sensors must be able to operate reliably within the environment itself. This requires the use of platinum wiring, ceramic insulators, and other specialized materials that do not break down from the heat.

Understanding the Trade-offs

Selecting a high-temperature material is never a simple choice. Engineers must balance performance with significant practical and economic constraints.

Cost vs. Performance

The elements used in high-temperature superalloys (nickel, cobalt, rhenium) are rare and expensive. The complex processing required for advanced ceramics further adds to the cost, making these materials orders of magnitude more expensive than conventional steel.

Brittleness vs. Strength

Many of the strongest materials at high temperatures, particularly ceramics, are very brittle at room temperature. This makes them difficult to machine and highly susceptible to catastrophic failure from impact or thermal shock.

Manufacturing and Repair

The same properties that make these materials durable also make them incredibly difficult to shape, weld, and machine. Manufacturing components often requires specialized techniques like investment casting or powder metallurgy, and field repairs can be nearly impossible.

Making the Right Choice for Your Goal

The optimal material is entirely dependent on the specific combination of thermal, mechanical, and chemical stresses it will face.

- If your primary focus is high mechanical load at extreme temperatures (e.g., turbine blades): Your solution will likely involve nickel- or cobalt-based superalloys, often enhanced with thermal barrier coatings.

- If your primary focus is thermal insulation and chemical inertness (e.g., furnace linings): Refractory ceramics like alumina, zirconia, or silicon carbide are the industry standard.

- If your primary focus is hypersonic flight or atmospheric re-entry: You must investigate carbon-carbon composites or ultra-high-temperature ceramics (UHTCs).

- If your primary focus is corrosion resistance in a high-temperature process (e.g., chemical reactors): You should look at high-nickel alloys or specialized stainless steels designed for that specific chemical environment.

Ultimately, selecting the correct high-temperature material is a critical engineering decision that directly dictates the performance, safety, and economic viability of your entire system.

Summary Table:

| Application Area | Key Challenge | Common High-Temperature Materials Used |

|---|---|---|

| Aerospace & Defense | Extreme heat in jet engines and atmospheric re-entry | Nickel-based superalloys, Thermal Barrier Coatings (TBCs), Carbon-Carbon Composites |

| Power Generation | High efficiency and stability in turbines and reactors | Superalloys, Zirconium alloys, Refractory ceramics |

| Industrial Processes | Containment and tooling for metal and glass manufacturing | Refractory ceramics (Alumina, Zirconia), High-temperature tool steels |

Ready to solve your high-temperature material challenge?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to test, analyze, and select the right high-temperature materials for your specific application—whether you're developing components for aerospace, power generation, or industrial manufacturing.

Our expertise helps you:

- Validate Material Performance: Accurately test creep resistance, oxidation, and thermal stability.

- Optimize Processes: Ensure your manufacturing and quality control meet the highest standards.

- Accelerate R&D: Access the right tools to push the boundaries of temperature and performance.

Let's discuss your project requirements. Contact our experts today to find the perfect solution for your high-temperature needs.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why should glass-ceramic green bodies be placed in a precision drying oven? Ensure Structural Integrity & High Yield

- How can we reduce plastic waste using technology? Leverage AI, Chemical Recycling & Bioplastics

- What is the advantage of sintered glass filter? Achieve Superior Purity and Precision in Your Lab Filtration

- What does the beam of electrons do to the vaporized sample? Ionize and Fragment for Compound Identification

- What are the disadvantages of biomass to the environment? Debunking the 'Green' Myth

- What is a challenge associated with electroplating sensing films? Achieving Uniformity for Reliable Sensors

- What is the thermal stability of graphene? A Guide to Temperature Limits and Material Selection

- Why must the Extremely fast Joule Heating (EJH) process be conducted in a low vacuum? Protect Your Metal Thin Films