In essence, a "diamond" ceramic coating represents the highest tier of automotive surface protection available. These coatings promise superior hardness, chemical resistance, and longevity compared to standard ceramic options. This enhanced performance is achieved not through literal diamonds, but through advanced chemical formulations with a higher concentration of active ingredients like Silicon Dioxide (SiO2) and, in some cases, the addition of Silicon Carbide (SiC) for added durability.

The term "diamond" in ceramic coatings is a marketing classification for the highest tier of durability and hardness, not an indication of actual diamond content. Your focus should be on the coating's specific chemical composition and tested longevity, as these are the true measures of performance, rather than the "diamond" label itself.

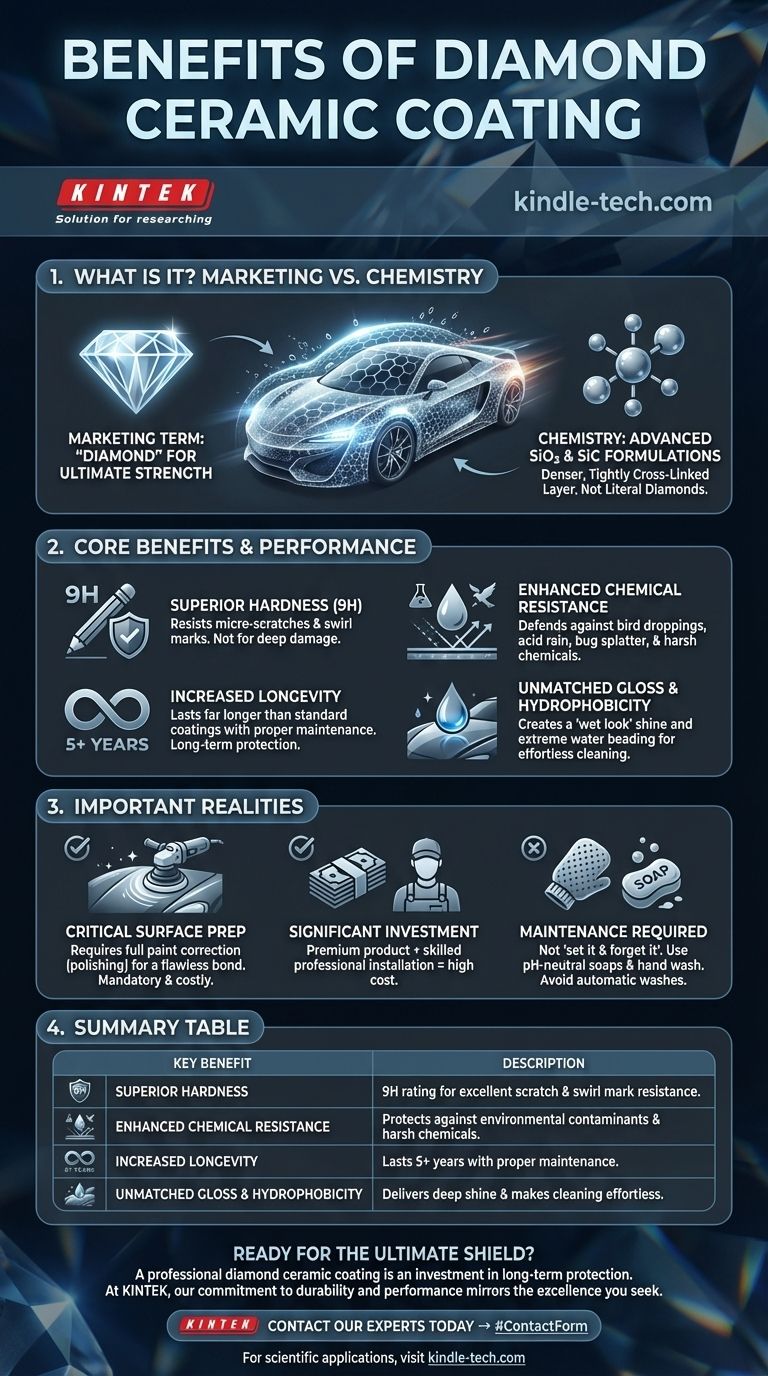

Deconstructing "Diamond": Marketing vs. Chemistry

To understand the benefits, we must first separate the marketing language from the underlying science. The term "diamond" is used to convey ultimate strength and performance.

The Foundation: Standard Ceramic Coatings

A standard ceramic coating is a liquid polymer containing Silicon Dioxide (SiO2) suspended in a solvent. When applied to your car's paint, the solvent evaporates, and the SiO2 cures to form a chemical bond with the clear coat. This creates a hard, sacrificial layer of protection.

The "Diamond" Label: A Symbol of Peak Performance

The "diamond" designation is used by manufacturers to signify their flagship product. It implies a formulation engineered for the most extreme durability, gloss, and protective capabilities that the brand offers.

The Chemistry Behind the Claim

The superior performance of these coatings comes from a more complex and concentrated chemical structure. They often contain a higher percentage of SiO2, creating a denser, more tightly cross-linked protective layer.

Many top-tier coatings also incorporate Silicon Carbide (SiC). SiC is an extremely hard and durable compound used in industrial applications, and its inclusion significantly increases the coating's resistance to abrasion and chemicals, lending credibility to the "diamond-like" marketing claim.

The Tangible Benefits of a High-Performance Coating

Moving past the name, a professional-grade or "diamond" coating delivers measurable improvements in protection and aesthetics.

Superior Hardness and Scratch Resistance

These coatings are often rated at 9H hardness on the pencil scale. This means they can resist scratches from the hardest graphite pencil, offering robust protection against micro-scratches and swirl marks induced by improper washing. It will not, however, protect against deep scratches or rock chips.

Enhanced Chemical Resistance

The dense, highly cross-linked molecular structure provides a formidable barrier against environmental contaminants. This includes superior resistance to bird droppings, bug splatter, acid rain, and harsh cleaning chemicals that could etch or damage the underlying clear coat.

Increased Longevity and Durability

While consumer-grade ceramic coatings typically last for one to two years, "diamond" or professional-grade coatings are formulated to last for five years or more with proper maintenance. This long-term performance is their primary value proposition.

Unmatched Gloss and Hydrophobicity

The perfectly smooth, dense surface created by a high-solids coating produces exceptional light reflection, resulting in a deeper, "wet look" gloss. It also creates extreme hydrophobicity, causing water to bead into tight, uniform spheres that roll off the surface effortlessly, taking dirt with them and making the vehicle significantly easier to clean.

Understanding the Trade-offs and Realities

While the benefits are significant, a decision to use a top-tier coating requires a clear understanding of the associated realities.

The Critical Role of Surface Preparation

No coating can hide existing imperfections. To achieve a proper bond and flawless finish, the vehicle's paint must be completely decontaminated and undergo a full paint correction (polishing) to remove all swirls, scratches, and defects before application. This step is mandatory and often constitutes a significant portion of the total cost.

Cost: A Significant Investment

"Diamond" coatings are premium products that almost always require professional installation due to their complex application process and rapid curing times. This combination of a high-cost product and skilled labor makes it a significant financial investment.

"Diamond" is Not a Standardized Term

There is no industry-wide standard for what constitutes a "diamond" coating. One brand's flagship "diamond" product may have a different formulation (e.g., high SiO2 vs. SiC-infused) than another's. You must look past the name and evaluate the specific product's technical data sheet and real-world reviews.

Maintenance is Still Required

These coatings are not a "set it and forget it" solution. To ensure longevity and performance, you must use proper washing techniques, including pH-neutral car soaps and clean microfiber towels. Automatic car washes with harsh brushes will degrade the coating and void most warranties.

Making the Right Choice for Your Vehicle

The decision to invest in a "diamond" level coating depends entirely on your goals for the vehicle, your budget, and your commitment to maintenance.

- If your primary focus is maximum long-term protection and value retention for a cherished vehicle: A professionally installed, high-solids "diamond" or SiC-based coating is the definitive choice.

- If your primary focus is improving ease of maintenance and gloss on a daily driver: A quality consumer-grade or entry-level professional ceramic coating provides an excellent return on investment for 1-3 years.

- If you are a DIY enthusiast looking for a project: Focus on well-reviewed consumer coatings with clear instructions, as perfecting the mandatory paint preparation process is the most critical skill to master.

Ultimately, view "diamond" as a signal for a brand's top-tier product, but always verify its performance through its technical data sheet and independent reviews.

Summary Table:

| Key Benefit | Description |

|---|---|

| Superior Hardness | 9H hardness rating for excellent scratch and swirl mark resistance. |

| Enhanced Chemical Resistance | Protects against bird droppings, acid rain, and harsh chemicals. |

| Increased Longevity | Lasts 5+ years with proper maintenance, far longer than standard coatings. |

| Unmatched Gloss & Hydrophobicity | Delivers a deep, wet-look shine and makes cleaning effortless. |

Ready to provide your vehicle with the ultimate shield?

A professional-grade diamond ceramic coating is a significant investment in long-term protection and value retention. At KINTEK, we understand the precision and quality required for superior surface treatments. While we specialize in lab equipment and consumables for scientific applications, our commitment to durability and performance mirrors the excellence you seek for your car's finish.

For inquiries about high-performance materials or to discuss your specific needs, contact our experts today. Let's achieve outstanding results together.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What are the challenges in the use of carbon nanotubes for biomedical applications? Navigating Toxicity and Safety Hurdles

- What are the applications of thin film in science and technology? Enabling Modern Electronics, Optics, and Energy

- Which coating is best for lenses? Build Custom Glasses for Your Vision and Lifestyle

- What are the applications of graphene in electronics? Revolutionizing Performance, Energy, and Durability

- What are the factors affecting optical properties? Master the Atomic and Microstructural Influences

- What materials are used in CVD? A Guide to Precursors, Substrates, and Deposited Films

- Why is synthetic HPHT diamond often preferred over natural diamond for industrial tools? Consistency vs. Chaos

- What materials and techniques are used to create thin films? Master Precision Deposition for Advanced Lab Research