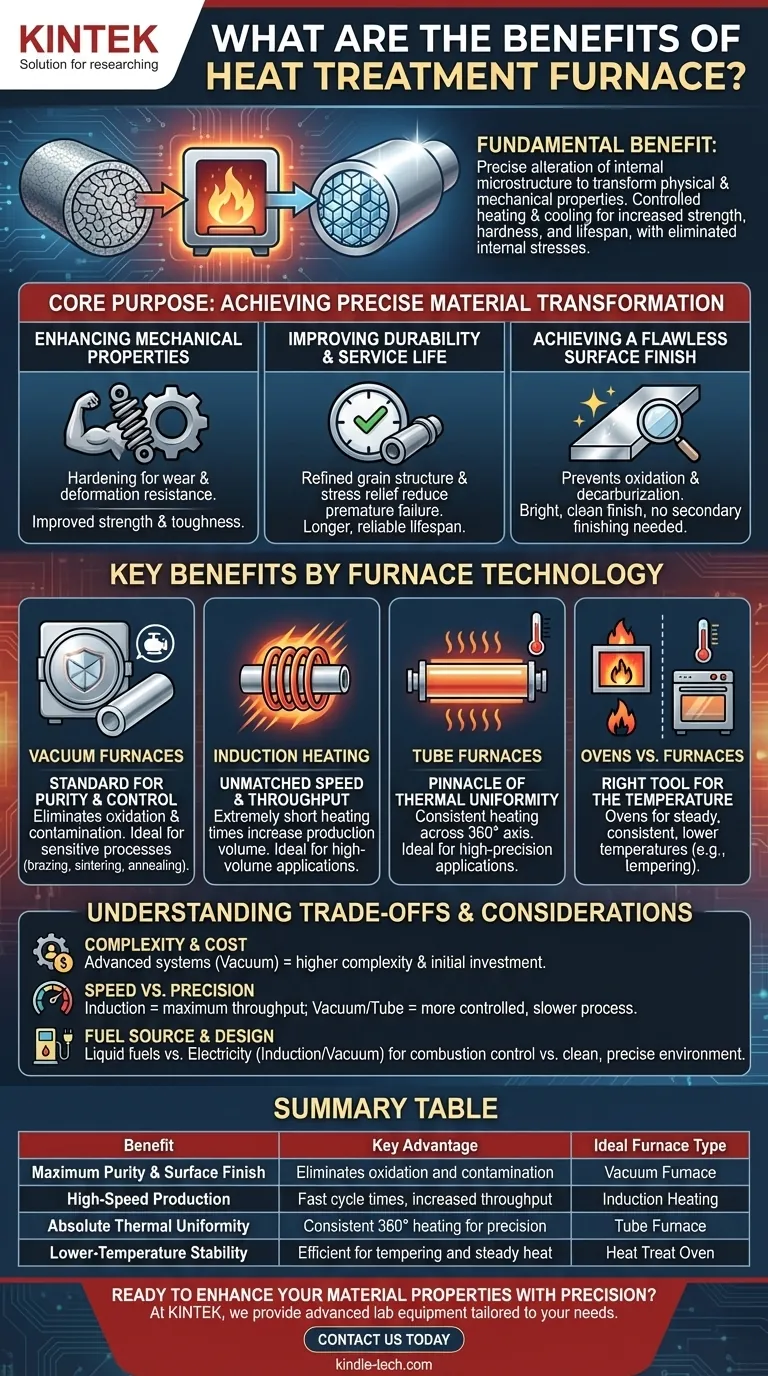

The fundamental benefit of a heat treatment furnace is its ability to precisely alter the internal microstructure of a material, fundamentally transforming its physical and mechanical properties. By applying controlled cycles of heating and cooling, these furnaces can increase a component's strength, hardness, and lifespan while eliminating internal stresses, all within a highly controlled environment that prevents surface contamination.

The greatest advantage of heat treatment is not simply heating a material, but gaining precise and repeatable control over its final characteristics. The choice of furnace technology—from vacuum to induction—directly determines the purity, speed, and uniformity of the final product.

The Core Purpose: Achieving Precise Material Transformation

Heat treatment is a critical manufacturing step designed to elicit specific, desirable characteristics from a material that it does not possess in its raw state.

Enhancing Mechanical Properties

Furnaces enable processes like hardening, which increases a material's resistance to wear and deformation. This controlled thermal processing rearranges the material's crystalline structure to achieve significant improvements in strength and toughness.

Improving Durability and Service Life

By refining the grain structure and relieving internal stresses introduced during manufacturing, heat treatment significantly reduces the risk of premature failure. This results in components with a much longer and more reliable service life.

Achieving a Flawless Surface Finish

Certain furnace technologies, particularly vacuum furnaces, perform their function in an environment free of atmospheric contaminants. This prevents oxidation and decarburization, producing a bright, clean surface that requires no secondary finishing.

Key Benefits by Furnace Technology

While all heat treatment furnaces modify materials, the specific technology used offers distinct advantages tailored to different outcomes.

Vacuum Furnaces: The Standard for Purity and Control

A vacuum furnace provides a clean, precisely controlled processing environment by removing the atmosphere. This eliminates the risk of oxidation and contamination, ensuring high-quality components with superior mechanical properties.

This process prevents undesirable surface reactions, resulting in a higher purity end product free of defects. It is the ideal method for sensitive processes like brazing, sintering, and annealing where atmospheric interference cannot be tolerated.

Induction Heating: Unmatched Speed and Throughput

The primary benefit of induction heat treating is its speed. The extremely short heating times dramatically increase production volume and throughput.

This efficiency directly translates to reduced labor costs and a more streamlined manufacturing process, making it ideal for high-volume applications where speed is critical.

Tube Furnaces: The Pinnacle of Thermal Uniformity

Tube furnaces are engineered to deliver unrivaled thermal uniformity. They ensure consistent heating over a part's entire 360° axis, which is critical for sensitive thermal processing.

This perfect heat distribution makes them the ideal choice for applications requiring the highest degree of precision, such as the calibration of thermocouples.

Ovens vs. Furnaces: The Right Tool for the Temperature

It's important to distinguish between furnaces and ovens. Heat treat ovens are perfect for processes that require maintaining a steady, consistent temperature without reaching the extreme heat of a furnace.

This makes them highly effective and efficient for lower-temperature applications, such as tempering steel.

Understanding the Trade-offs and Considerations

Choosing the right technology requires a clear understanding of the inherent compromises between complexity, cost, and performance.

Complexity and Cost

Advanced systems like vacuum furnaces offer superior results but come with increased complexity. They often have a complex structure, require high-power pumping systems, and may need specialized low-voltage, high-current power supplies, all of which impact the initial investment.

Speed vs. Precision

There is often a trade-off between the speed of the process and the level of control. Induction heating offers maximum throughput, while vacuum and tube furnaces provide a more controlled, slower process that ensures maximum purity and uniformity.

Fuel Source and Furnace Design

The choice of energy source, such as liquid fuels or electricity, also plays a role. Liquid fuels can offer easier combustion control and simpler furnace designs, but electric systems like induction and vacuum offer a cleaner, more precise environment.

Making the Right Choice for Your Goal

Your final decision should be based on the specific material properties and production metrics you need to achieve.

- If your primary focus is maximum purity and a flawless surface finish: A vacuum furnace is the definitive choice for eliminating all atmospheric contamination.

- If your primary focus is high-volume production and speed: Induction heating offers the fastest cycle times and highest throughput, reducing labor costs.

- If your primary focus is absolute temperature consistency for sensitive parts: A tube furnace provides unparalleled thermal uniformity for high-precision applications.

- If your primary focus is lower-temperature processes like tempering: A dedicated heat treat oven provides the necessary stability without the cost or complexity of a high-temperature furnace.

Ultimately, the right heat treatment furnace is the one that gives you precise, repeatable control over your material's final properties.

Summary Table:

| Benefit | Key Advantage | Ideal Furnace Type |

|---|---|---|

| Maximum Purity & Surface Finish | Eliminates oxidation and contamination | Vacuum Furnace |

| High-Speed Production | Fast cycle times, increased throughput | Induction Heating |

| Absolute Thermal Uniformity | Consistent 360° heating for precision | Tube Furnace |

| Lower-Temperature Stability | Efficient for tempering and steady heat | Heat Treat Oven |

Ready to enhance your material properties with precision? At KINTEK, we specialize in providing advanced lab equipment, including heat treatment furnaces tailored to your specific needs—whether you require the purity of vacuum systems, the speed of induction heating, or the uniformity of tube furnaces. Our experts are here to help you achieve superior strength, durability, and performance in your components. Contact us today to discuss your application and discover the perfect solution for your laboratory!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost