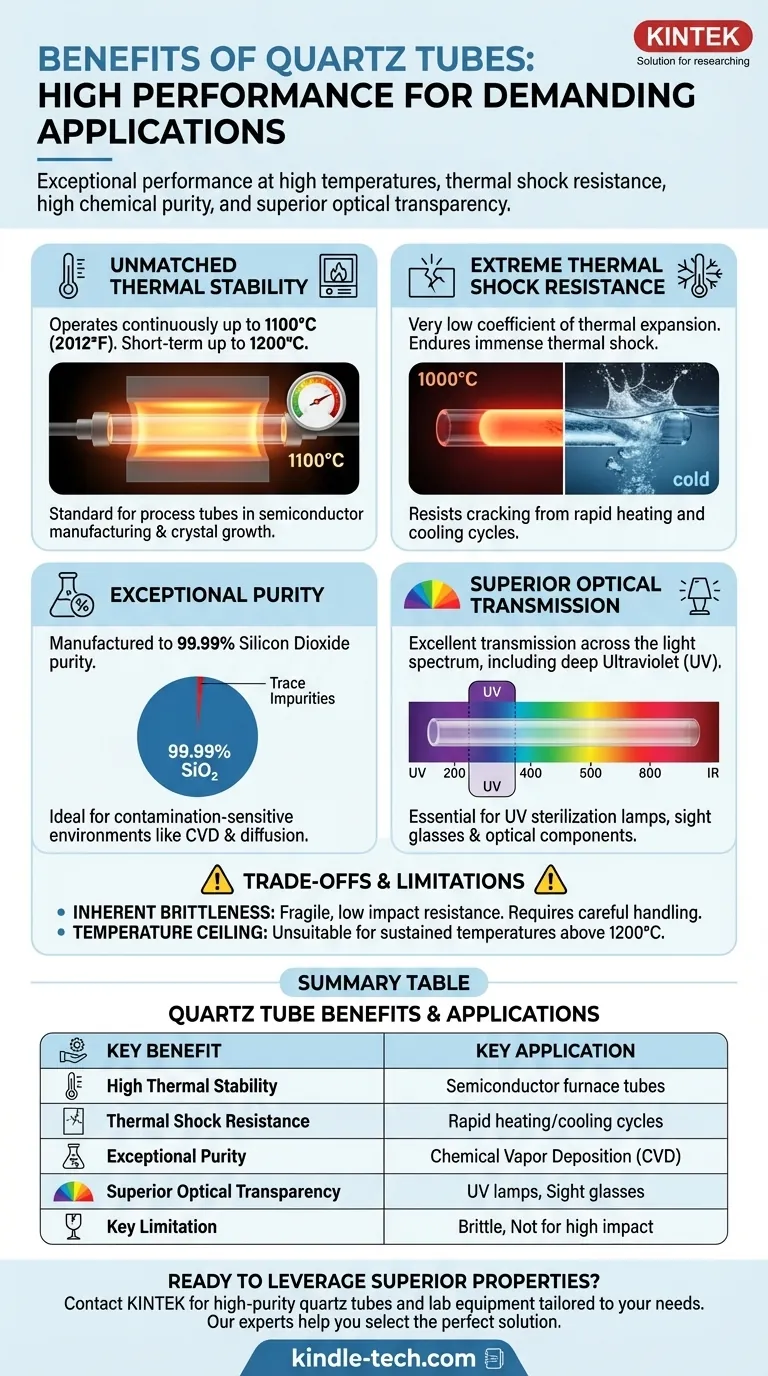

The primary benefits of a quartz tube are its exceptional performance at high temperatures, its resistance to sudden temperature changes (thermal shock), its high chemical purity, and its superior optical transparency, particularly to ultraviolet light. These properties make it an essential material for specialized scientific and industrial applications where other materials would fail.

While often chosen for its ability to withstand extreme heat and transmit light, the true value of quartz lies in its unique combination of thermal, chemical, and optical properties. Understanding these attributes is key to knowing when to use it and, just as importantly, when to choose an alternative.

Why Quartz Excels in Demanding Environments

The unique molecular structure of fused quartz is what gives it its highly desirable characteristics. It is not simply a type of glass; it is a high-performance ceramic engineered for specific, challenging tasks.

Unmatched Thermal Stability

Quartz tubes can operate continuously at temperatures up to 1100°C (2012°F). They can even handle short-term exposure up to 1200°C before they begin to soften and deform.

This makes them the standard material for process tubes in high-temperature furnaces, such as those used for semiconductor manufacturing and crystal growth.

Extreme Thermal Shock Resistance

High-purity fused quartz has an extremely low coefficient of thermal expansion. This means it barely expands or contracts when heated or cooled.

As a result, it can endure immense thermal shock without cracking, such as being heated to 1000°C and then rapidly cooled to room temperature.

Exceptional Purity

Quartz tubes can be manufactured to a purity of 99.99% silicon dioxide. This near-total lack of contaminants is critical for processes where even trace amounts of impurities would ruin the outcome.

Applications like Chemical Vapor Deposition (CVD) and diffusion procedures in the semiconductor industry rely on this purity to maintain the integrity of the process environment.

Superior Optical Transmission

Unlike most types of glass, fused quartz offers excellent transmission across the entire light spectrum, including deep into the ultraviolet (UV) range.

This property is essential for UV sterilization lamps, sight glasses for monitoring high-temperature reactions, and optical components like lenses and windows used in scientific instruments. In high-intensity lamps, its purity also reduces clouding (devitrification), extending the operational life of the bulb.

Understanding the Trade-offs and Limitations

No material is perfect. The strengths of quartz come with inherent weaknesses that are critical to understand before specifying it for a project.

Inherent Brittleness

The biggest drawback of quartz is its fragility. Like other ceramics, it is brittle and has very low impact resistance.

It requires special care during handling, installation, and operation. Violent vibrations or physical collisions can easily cause it to shatter, leading to costly failures.

The Temperature Ceiling

While its high-temperature performance is excellent, it has a firm limit. For applications requiring sustained temperatures above 1200°C, quartz is unsuitable.

In these cases, more advanced ceramics like a corundum (alumina) tube must be used, which can withstand significantly higher heat at the cost of optical transparency.

Not All Quartz Is Created Equal

The term "quartz" can refer to products with varying compositions and manufacturing methods. The properties of a tube depend heavily on its specific grade and purity.

It is essential to check the manufacturer's specifications to ensure the material's thermal, optical, and chemical characteristics align with the demands of your specific application.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is high-temperature, high-purity processing: Quartz is the ideal choice for furnace tubes in applications like semiconductor manufacturing, provided you operate below its 1200°C limit.

- If your primary focus is optical clarity and UV transmission: Fused quartz is unparalleled for making UV lamps, sight glasses, and optical components that must operate in harsh thermal environments.

- If your primary focus is mechanical durability: The brittleness of quartz makes it a poor choice for environments with high vibration, physical stress, or risk of impact.

By understanding both its unique strengths and its critical limitations, you can confidently specify quartz for the applications where it truly excels.

Summary Table:

| Key Benefit | Description | Key Application |

|---|---|---|

| High Thermal Stability | Withstands continuous temperatures up to 1100°C (2012°F) | High-temperature furnace tubes for semiconductor processing |

| Thermal Shock Resistance | Low coefficient of thermal expansion prevents cracking from rapid temperature changes | Processes requiring rapid heating and cooling cycles |

| Exceptional Purity | 99.99% silicon dioxide purity, ideal for contamination-sensitive environments | Chemical Vapor Deposition (CVD), diffusion processes |

| Superior Optical Transparency | Excellent transmission of UV light and across the spectrum | UV sterilization lamps, sight glasses, optical components |

| Key Limitation | Brittle and fragile; requires careful handling | Not suitable for high-vibration or high-impact environments |

Ready to leverage the superior properties of quartz tubes in your lab?

At KINTEK, we specialize in providing high-purity quartz tubes and other essential lab equipment tailored to the demanding needs of semiconductor manufacturing, research, and industrial applications. Our products ensure the thermal stability, chemical purity, and optical clarity your processes require.

Let our experts help you select the perfect quartz tube for your specific application.

Contact KINTEK today to discuss your requirements and discover how our solutions can enhance your lab's performance and reliability.

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why must ZrO2 grinding jars be used for sulfide solid electrolytes? Essential Purity for High-Performance Batteries

- Why are a K-type thermocouple and a temperature regulator necessary for stainless steel heat treatment? Master Precision

- What device can be used to measure the partial pressure of residual gases in a vacuum? A Residual Gas Analyzer (RGA) provides the definitive answer.

- What is the purpose of using an aluminum silicate fiber bed? Unlock True Kinetic Data for Your TGA Experiments

- Why are zirconia grinding balls preferred for NiCrAlY-Mo-Ag powders? Ensure Maximum Purity and Durability

- What material is used in refractory? A Guide to High-Temperature Material Selection

- What is the role of stainless steel ball milling jars and grinding balls in the mechanochemical synthesis of Li3P or Li3N?

- What is the maximum pressure for a vacuum pump? Understanding Ultimate Vacuum for Your Lab Needs