In short, the primary benefits of Spark Plasma Sintering (SPS) are its exceptional speed, lower processing temperatures, and ability to produce materials with superior density and finer microstructures. This advanced technique uses a pulsed electric current to heat materials directly, drastically reducing the time and energy required for densification compared to conventional sintering methods.

Spark Plasma Sintering is not just a faster version of traditional heating; it is a fundamentally different approach. By using an electric current to generate heat directly within the material and its mold, it activates densification mechanisms at lower temperatures and in a fraction of the time, preserving the material's inherent properties.

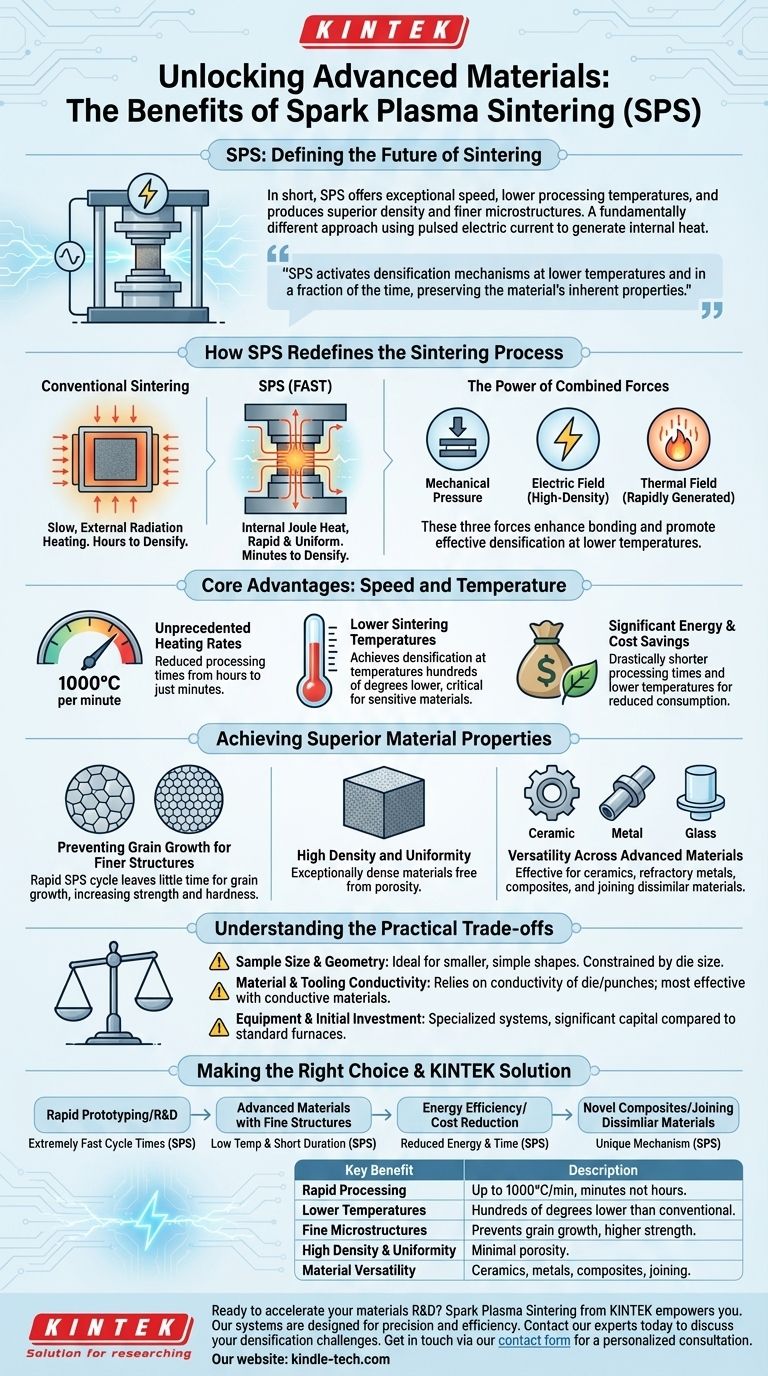

How SPS Redefines the Sintering Process

To understand the benefits of SPS, it's crucial to understand its unique mechanism, which sets it apart from conventional furnace-based methods like hot pressing.

The Unique Heating Mechanism

Traditional methods heat a sample externally using radiation from a heating element, a slow process where heat gradually soaks into the material.

SPS, also known as a Field-Assisted Sintering Technique (FAST), passes a powerful electric current directly through a conductive die (typically graphite) and, in many cases, through the powdered sample itself.

This generates instantaneous Joule heat from within, resulting in extremely rapid and uniform temperature increases.

The Power of Combined Forces

SPS applies three forces simultaneously: a uniaxial mechanical pressure, a high-density electric field, and a rapidly generated thermal field.

This combination works to enhance the bonding between material particles, promoting densification much more effectively and at lower temperatures than heat and pressure alone.

The Core Advantages: Speed and Temperature

The most significant and immediate benefits of the SPS mechanism are its speed and thermal efficiency.

Unprecedented Heating Rates

SPS can achieve heating rates of up to 1000°C per minute.

This incredible speed reduces processing times from many hours, typical for conventional sintering, down to just a few minutes.

Lower Sintering Temperatures

The active electric field helps densify materials at temperatures often several hundred degrees lower than those required by other methods.

This is especially critical for materials that are sensitive to high temperatures or prolonged heat exposure.

Significant Energy and Cost Savings

The combination of drastically shorter processing times and lower temperatures directly translates to reduced energy consumption and lower operational costs, making it a more efficient manufacturing process.

Achieving Superior Material Properties

The speed and low temperatures of SPS are not just about efficiency; they are key to producing higher-performance materials.

Preventing Grain Growth for Finer Structures

In traditional sintering, long exposure to high temperatures causes the microscopic grains of the material to grow larger, which can weaken the final product.

The rapid SPS cycle gives these grains very little time to grow, resulting in a final material with a fine-grained microstructure, which typically means higher strength and hardness.

High Density and Uniformity

The uniform internal heating and applied pressure allow SPS to produce materials that are exceptionally dense and free from the porosity that can plague other methods.

Versatility Across Advanced Materials

SPS is highly effective for a wide range of materials that are often difficult to process, including ceramics, refractory metals, gradient composites, and amorphous materials like glass.

It also has the unique ability to join or "weld" dissimilar materials, such as ceramic-to-metal, creating strong bonds that are difficult to achieve otherwise.

Understanding the Practical Trade-offs

While powerful, SPS is not a universal solution. Objectivity requires acknowledging its limitations.

Sample Size and Geometry

The process is constrained by the size of the conductive die. This makes SPS ideal for producing smaller, simple-shaped parts but less suitable for manufacturing very large or geometrically complex components.

Material and Tooling Conductivity

The efficiency of SPS relies on the electrical conductivity of the graphite die and punches. While non-conductive powders can be sintered, the process is most effective when the material itself has some conductivity to aid in Joule heating.

Equipment and Initial Investment

SPS systems are highly specialized and represent a significant capital investment compared to standard high-temperature furnaces used for conventional sintering.

Making the Right Choice for Your Application

Selecting the right sintering method depends entirely on your project's goals.

- If your primary focus is rapid prototyping or R&D: The extremely fast cycle times of SPS make it an unparalleled tool for iterating on new materials quickly.

- If your primary focus is producing advanced materials with fine-grained microstructures: The low temperature and short duration of SPS are critical for preventing grain growth and maximizing material performance.

- If your primary focus is energy efficiency and cost reduction: SPS significantly cuts energy consumption and operational time compared to multi-hour conventional processes.

- If your primary focus is creating novel composites or joining dissimilar materials: The unique mechanism of SPS makes it one of the few viable options for these challenging applications.

Ultimately, Spark Plasma Sintering empowers engineers and scientists to create next-generation materials that were previously difficult or impossible to densify effectively.

Summary Table:

| Key Benefit | Description |

|---|---|

| Rapid Processing | Heating rates up to 1000°C/min, reducing cycle times from hours to minutes. |

| Lower Temperatures | Achieves densification at temperatures several hundred degrees lower than conventional methods. |

| Fine Microstructures | Prevents grain growth, resulting in higher strength and hardness. |

| High Density & Uniformity | Produces exceptionally dense materials with minimal porosity. |

| Material Versatility | Effective for ceramics, refractory metals, composites, and joining dissimilar materials. |

Ready to accelerate your materials R&D and manufacturing with next-generation sintering?

Spark Plasma Sintering from KINTEK empowers you to create advanced materials with superior properties, faster than ever before. Our SPS systems are designed for researchers and engineers working with ceramics, metals, and composites who demand precision, efficiency, and unparalleled performance.

Contact our experts today to discuss how SPS can solve your specific densification challenges and unlock new possibilities for your lab. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- Does sintering require pressure? Unlock the Right Method for Your Material Density

- What are the advantages of using a vacuum hot pressing furnace? Superior Densification for 2024Al/Gr/SiC Composites

- How do the long holding times and high vacuum of hot pressing improve diamond/aluminum bonding? Key Mechanisms Revealed

- What are the core advantages of using a vacuum hot pressing furnace for Cu/WC composites? Superior Density & Bonding

- Which core process conditions does a vacuum hot pressing sintering furnace provide for ZrB2-SiC layered ceramics?

- What are the process advantages of using a vacuum hot press vs. HIP? Simplify your steel preparation workflow.

- What key processing conditions does a vacuum hot press furnace provide? Optimize Cu/Ti3SiC2/C Nanocomposite Sintering

- What products are made by hot pressing? Achieve Maximum Density and Performance for Your Components