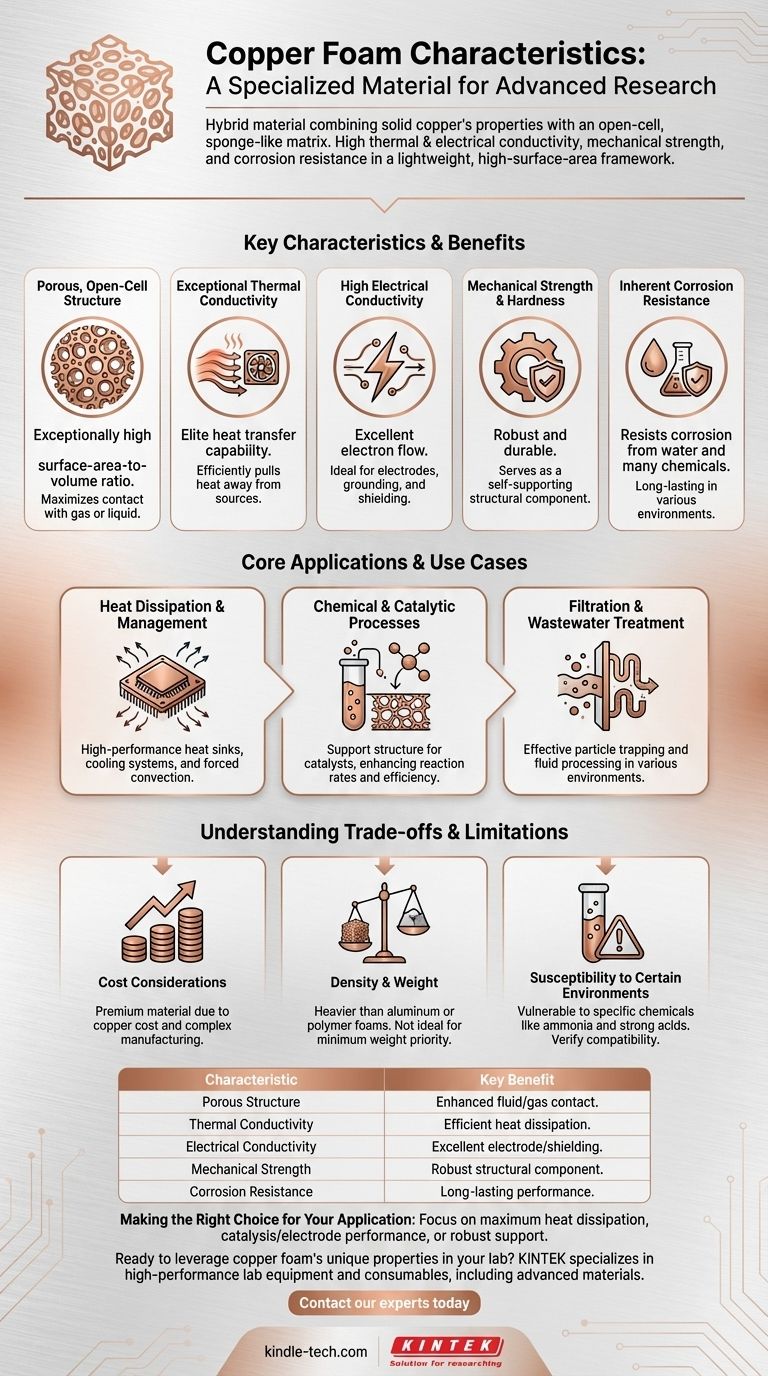

At its core, copper foam is a highly specialized material that combines the intrinsic properties of solid copper with the structural benefits of an open-cell, sponge-like matrix. This results in a material that possesses excellent thermal and electrical conductivity, high mechanical strength, and notable corrosion resistance, all within a lightweight, high-surface-area framework.

Copper foam's primary value lies in its dual nature: it performs like solid metal where conductivity is key, but acts like a porous medium where surface area and fluid flow are critical. This makes it an exceptional material for accelerating thermal, electrical, and chemical processes.

Deconstructing the Key Characteristics

To truly understand copper foam's potential, we must examine the interplay of its foundational properties. Each characteristic enables a specific set of applications.

The Porous, Open-Cell Structure

The most defining feature of copper foam is its network of interconnected voids, similar to a sponge.

This structure creates an exceptionally high surface-area-to-volume ratio. This is crucial for applications that depend on maximizing contact with a gas or liquid.

Exceptional Thermal Conductivity

Copper is one of the best practical thermal conductors, and copper foam retains this elite capability.

The interconnected metal ligaments form a continuous, three-dimensional path for heat to travel rapidly through the material, pulling it away from a source with extreme efficiency.

High Electrical Conductivity

Just as it conducts heat, copper foam is an excellent electrical conductor. The metallic matrix allows electrons to flow with very low resistance.

This property makes it suitable for advanced electrodes, grounding applications, or shielding where airflow is also a requirement.

Mechanical Strength and Hardness

Unlike many other porous materials like polymer or ceramic foams which can be brittle or soft, copper foam is robust.

It maintains a high degree of strength and hardness, allowing it to serve as a self-supporting structural component in demanding environments.

Inherent Corrosion Resistance

Copper naturally resists corrosion from water and many chemicals. This property is passed directly to the foam.

This makes it a durable choice for use in filtration, fluid processing, and long-term exposure to ambient environmental conditions.

Where These Properties Excel: Core Applications

The unique combination of these characteristics makes copper foam the ideal solution for several specific technical challenges.

Heat Dissipation and Management

This is a primary use case. The high thermal conductivity efficiently draws heat away from electronic components, while the open structure allows air or liquid coolants to flow through, removing the heat rapidly.

Chemical and Catalytic Processes

The vast surface area makes copper foam an excellent support structure for catalysts. More surface area means more sites for chemical reactions to occur, dramatically increasing process efficiency.

Filtration and Wastewater Treatment

The uniform, tortuous path through the foam's structure is effective for trapping particulate matter. Its corrosion resistance ensures longevity when used with various fluids.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the limitations of copper foam is critical for proper application.

Cost Considerations

Copper is a more expensive raw material than alternatives like aluminum. The complex manufacturing process for foam further adds to its cost, making it a premium solution.

Density and Weight

While significantly lighter than a solid block of copper, it is much heavier than aluminum foam or polymer-based foams. It is not the ideal choice for applications where minimizing weight is the absolute top priority.

Susceptibility to Certain Environments

Though generally robust, copper is susceptible to attack from specific chemicals, such as ammonia and certain strong acids. Environmental compatibility must always be verified.

Making the Right Choice for Your Application

To decide if copper foam is the correct material, consider your primary engineering goal.

- If your primary focus is maximum heat dissipation: Copper foam is an elite choice for high-performance heat sinks, especially in forced convection (air or liquid) systems.

- If your primary focus is catalysis or electrode performance: The immense, conductive surface area makes it an ideal platform for enhancing reaction rates and electrochemical efficiency.

- If your primary focus is lightweight structural support: You should likely look elsewhere; materials like aluminum foam or composites offer better strength-to-weight ratios.

- If your primary focus is cost-sensitive design: Standard extruded aluminum heat sinks or other conventional materials will almost always be a more economical choice.

By understanding this unique interplay of conductivity, structure, and strength, you can leverage copper foam to solve complex engineering challenges that solid materials simply cannot address.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Porous, Open-Cell Structure | High surface area for enhanced fluid/gas contact |

| Exceptional Thermal Conductivity | Efficient heat dissipation and management |

| High Electrical Conductivity | Excellent electron flow for electrodes and shielding |

| Mechanical Strength & Hardness | Robust, self-supporting structural component |

| Inherent Corrosion Resistance | Long-lasting performance in various environments |

Ready to leverage copper foam's unique properties in your lab? KINTEK specializes in high-performance lab equipment and consumables, including advanced materials like copper foam. Whether you're designing a cutting-edge heat sink, a catalytic reactor, or a filtration system, our expertise can help you select the right materials for maximum efficiency. Contact our experts today to discuss how our solutions can accelerate your research and development.

Visual Guide

Related Products

- Copper Foam

- Copper Nickel Foam Metal Sheet

- High Purity Zinc Foil for Battery Lab Applications

- High Purity Gold Platinum Copper Iron Metal Sheets

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- What is copper foam used for? A Guide to Its High-Performance Thermal and Energy Applications

- What are the proper storage conditions for nickel and copper foam? A Guide to Preserving Performance

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids