To ensure maximum performance and longevity, the proper storage of nickel and copper foam hinges on maintaining a controlled environment. These materials must be kept in a dry, well-ventilated area, completely isolated from moisture and corrosive chemical agents like strong acids or alkalis. This prevents the degradation of their unique porous structure and sensitive surface chemistry.

The core challenge is not just storing the foam, but preserving its specific functional properties—such as high surface area and electrical conductivity. Effective material handling is a lifecycle concern, extending from initial storage through post-use cleaning and validation.

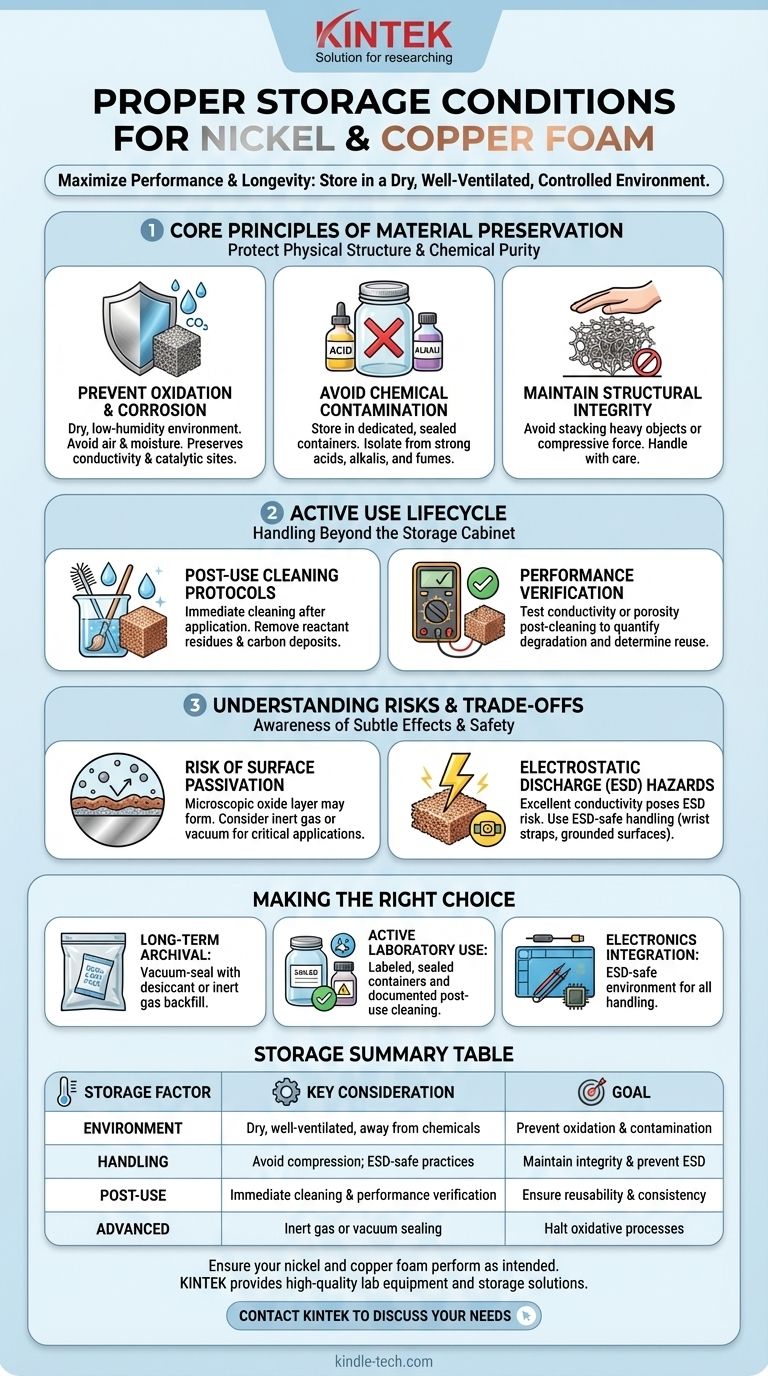

Core Principles of Material Preservation

The goal of any storage protocol is to protect the foam's physical structure and chemical purity. These materials are valued for their high surface-area-to-volume ratio, which also makes them highly susceptible to environmental degradation.

Preventing Oxidation and Corrosion

Both nickel and, more significantly, copper are prone to oxidation when exposed to air and moisture. This process forms a non-conductive and chemically inert oxide layer on the metal's surface.

This surface corrosion can severely compromise the foam's performance, reducing its electrical conductivity for electrode applications or deactivating its catalytic sites for chemical reactions. A dry, low-humidity environment is the first line of defense.

Avoiding Chemical Contamination

The vast, intricate surface of the foam acts like a sponge for airborne chemical agents. Exposure to corrosive fumes, such as those from strong acids or alkalis, can rapidly etch and destroy the delicate metal ligaments.

Even trace contaminants can "poison" the foam's surface, rendering it useless for sensitive applications. Store these materials in dedicated, sealed containers away from general chemical storage.

Maintaining Structural Integrity

While chemically robust under the right conditions, the foam's physical structure is delicate. The material is highly porous and can be easily crushed or deformed.

Avoid stacking heavy objects on the foam or storing it in a way that applies compressive force. Physical damage can close off pores, which permanently alters its porosity and fluid flow characteristics.

Beyond Storage: An Active Use Lifecycle

For materials used in research or production, proper handling extends far beyond the storage cabinet. The period after use is a critical window for preservation.

Post-Use Cleaning Protocols

After an application, such as a catalytic reaction or electrochemical process, immediately clean any residual substances from the foam's surface. Reactant residues or carbon deposits must be removed before they permanently bond to or corrode the material.

Following a documented cleaning procedure ensures the foam's active surface is restored and ready for its next use, preventing cross-contamination between experiments.

Performance Verification

After cleaning, it is wise to test the foam's key properties, such as electrical conductivity or porosity. This allows you to quantify any degradation that may have occurred during use.

This data provides an objective basis for deciding whether the material can be reliably reused or if it needs to be retired and replaced, ensuring process consistency.

Understanding the Risks and Trade-offs

Proper handling requires awareness of not only obvious corrosion but also more subtle performance-altering effects and safety hazards.

The Risk of Surface Passivation

Even in a seemingly clean and dry environment, a microscopic oxide layer, known as a passivation layer, can slowly form. While this can offer some protection against further corrosion, it also alters the surface's electrical and chemical properties.

For high-frequency electronics or highly sensitive catalysts, this effect can be a significant variable. For critical applications, storage in an inert gas environment (like argon or nitrogen) or under vacuum may be necessary.

Electrostatic Discharge (ESD) Hazards

The excellent electrical conductivity of nickel and copper foam presents an often-overlooked risk: electrostatic discharge (ESD). The foam can act as a rapid conduit for static electricity.

If used near sensitive electronic components, an ESD event through the foam can cause permanent damage to the device. Always use ESD-safe handling procedures, including wrist straps and grounded work surfaces, when incorporating these materials into electronic assemblies.

Making the Right Choice for Your Application

Your storage strategy should be directly aligned with the intended use case and required performance level of the foam.

- If your primary focus is long-term archival: Consider vacuum-sealing the foam with a desiccant pack or storing it in a container backfilled with an inert gas to completely halt oxidative processes.

- If your primary focus is active laboratory use: Implement a system of clearly labeled, sealed containers for storage and a rigorous, documented protocol for post-use cleaning and validation.

- If your primary focus is integration with sensitive electronics: Your entire handling process, from storage to assembly, must take place in an ESD-safe environment to prevent catastrophic device failure.

Ultimately, treating these advanced materials with a disciplined and proactive handling strategy is essential to realizing their full performance potential.

Summary Table:

| Storage Factor | Key Consideration | Goal |

|---|---|---|

| Environment | Dry, well-ventilated, away from corrosive chemicals | Prevent oxidation and chemical contamination |

| Handling | Avoid physical compression; use ESD-safe practices for electronics | Maintain structural integrity and prevent electrostatic discharge |

| Post-Use | Immediate cleaning and performance verification (conductivity, porosity) | Ensure reusability and process consistency |

| Advanced Preservation | Inert gas (Argon/Nitrogen) or vacuum sealing for critical applications | Halt all oxidative processes for long-term archival |

Ensure your nickel and copper foam perform as intended. Proper storage and handling are critical for maintaining the high surface area, electrical conductivity, and catalytic activity of these advanced materials. KINTEK specializes in providing high-quality lab equipment and consumables, including storage solutions tailored for sensitive materials. Our experts can help you design a storage and handling protocol that protects your investment and ensures experimental consistency.

Contact our team today to discuss your specific laboratory needs and how we can support your research.

Visual Guide

Related Products

- Copper Foam

- High Purity Zinc Foil for Battery Lab Applications

- Aluminum Foil Current Collector for Lithium Battery

- Gold Disc Electrode

- Ball Press Mold for Lab

People Also Ask

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- Is copper foam safe? Discover the facts about its antimicrobial and cooling benefits

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage

- What are the available sizes and thicknesses for copper foam? Optimize Your Thermal and Filtration Performance