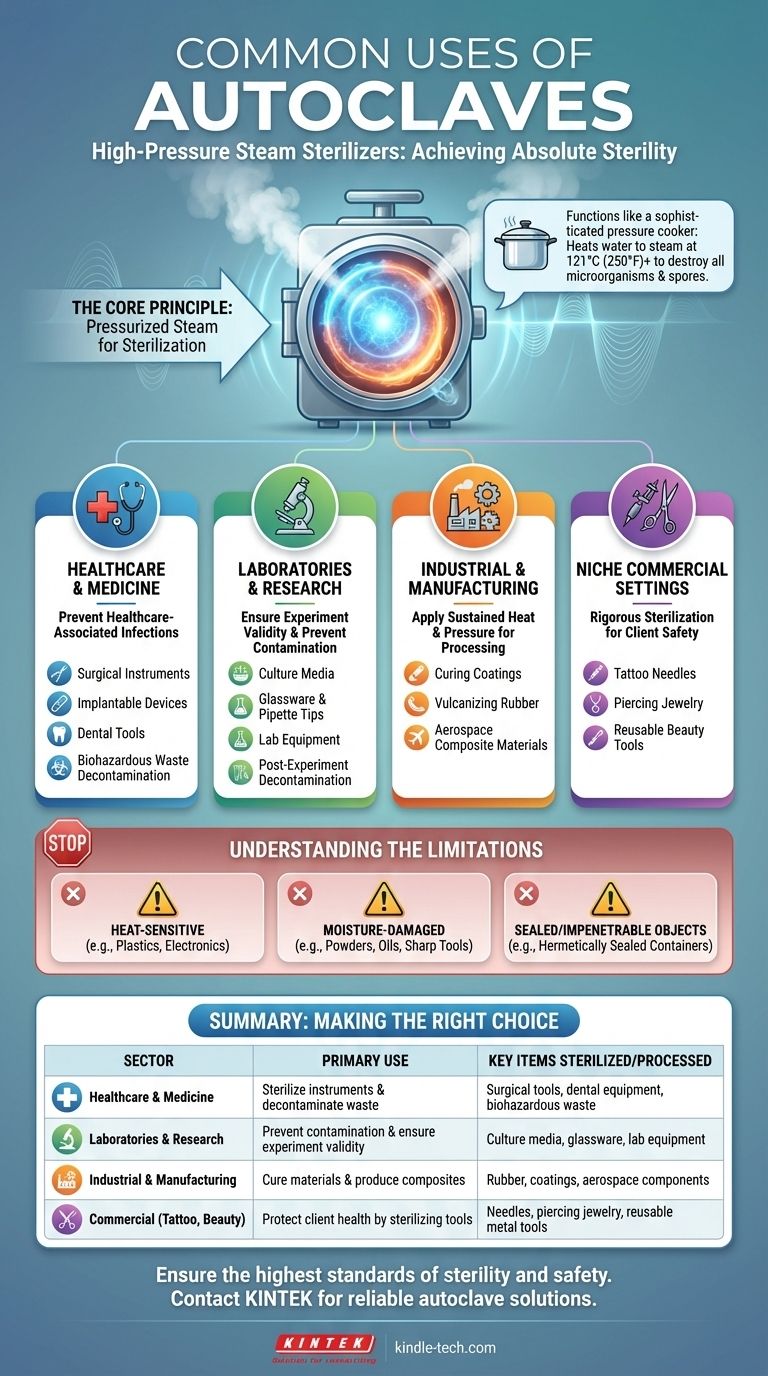

In essence, an autoclave is a high-pressure steam sterilizer. Its primary use is to destroy all forms of microbial life, including bacteria, viruses, fungi, and highly resilient spores, on equipment and materials. This makes it an indispensable tool in any setting where absolute sterility is required, from hospitals and research labs to certain industrial and commercial environments.

The core function of an autoclave is not merely cleaning, but achieving complete sterilization. By using pressurized steam to reach temperatures above the boiling point of water, it eliminates microorganisms that are resistant to simple boiling and chemical disinfectants.

The Core Principle: Why Steam Sterilization is Essential

Beyond Simple Cleaning

Standard cleaning removes visible dirt, and disinfection reduces the number of pathogens, but neither process guarantees the elimination of all microbial life.

Sterilization is the process of destroying or removing all microorganisms, including bacterial spores, which are notoriously difficult to kill. This is the level of purity that autoclaves are designed to achieve.

The Power of Pressurized Steam

An autoclave functions like a sophisticated pressure cooker. By increasing the pressure inside its sealed chamber, it can heat water into steam that reaches temperatures of 121°C (250°F) or higher.

This high-temperature, high-pressure steam rapidly penetrates materials and denatures the essential proteins and enzymes within microorganisms, rendering them non-functional and ensuring they are killed.

Primary Applications by Sector

The need for complete sterility cuts across numerous fields, making the autoclave a cornerstone of modern safety and quality control.

In Healthcare and Medicine

This is the most well-known application. Autoclaves are critical for preventing healthcare-associated infections.

Common uses include sterilizing surgical instruments, implantable medical devices, dental tools, and reusable medical supplies. They are also used to decontaminate and sterilize biohazardous waste before disposal.

In Laboratories and Research

Maintaining a sterile environment is fundamental to the validity of scientific research, particularly in microbiology, molecular biology, and biotechnology.

Researchers use autoclaves to sterilize culture media, glassware, pipette tips, and other lab equipment to prevent contamination of experiments. After an experiment, they are used again to decontaminate cultures and materials before they are safely discarded.

In Industrial and Manufacturing Processes

While sterilization is one function, industry also leverages the autoclave's ability to apply sustained heat and pressure.

In the chemical industry, autoclaves are used for curing coatings and vulcanizing rubber, processes that require specific temperature and pressure conditions. The aerospace and high-performance automotive industries use large autoclaves to manufacture advanced composite materials.

In Niche Commercial Settings

Any industry where instruments penetrate the skin requires rigorous sterilization to protect client health.

This includes tattoo studios and beauty salons, where autoclaves are used to sterilize needles, piercing jewelry, and other reusable metal tools to the same standards as medical equipment.

Understanding the Limitations of Autoclaving

While incredibly effective, an autoclave is not a universal solution. The process relies on high heat and moisture, which dictates what can and cannot be safely sterilized.

Heat-Sensitive Materials

Many materials cannot withstand the high temperatures inside an autoclave. This includes most plastics, which will melt or deform, and complex electronics, which will be destroyed.

Items Damaged by Moisture

The process is fundamentally based on steam, making it unsuitable for items that must remain dry. This includes certain powders, oils, and sharp instruments that may become dull due to oxidation from the moisture.

Sealed, Impenetrable Objects

For steam to work, it must make direct contact with all surfaces. Autoclaving is ineffective for sterilizing the contents of hermetically sealed containers or items wrapped in materials that steam cannot penetrate.

Making the Right Choice for Your Goal

The decision to use an autoclave is determined by your material and your objective.

- If your primary focus is preventing infection in a clinical setting: Autoclaving is the gold standard for sterilizing reusable, heat-resistant surgical and dental instruments.

- If your primary focus is ensuring valid results in a research lab: The autoclave is essential for both preparing sterile media and equipment before an experiment and decontaminating waste afterward.

- If your primary focus is an industrial production process: The autoclave serves as a critical tool for applying precise heat and pressure to cure materials or produce high-strength composites.

Ultimately, the autoclave is a powerful instrument that enables safety, precision, and reliability across science, medicine, and industry.

Summary Table:

| Sector | Primary Use | Key Items Sterilized/Processed |

|---|---|---|

| Healthcare & Medicine | Sterilize instruments & decontaminate waste | Surgical tools, dental equipment, biohazardous waste |

| Laboratories & Research | Prevent contamination & ensure experiment validity | Culture media, glassware, lab equipment |

| Industrial & Manufacturing | Cure materials & produce composites | Rubber, coatings, aerospace components |

| Commercial (e.g., Tattoo, Beauty) | Protect client health by sterilizing tools | Needles, piercing jewelry, reusable metal tools |

Ensure the highest standards of sterility and safety in your lab or facility. KINTEK specializes in providing reliable autoclaves and lab equipment to meet your specific needs, whether for medical sterilization, research integrity, or industrial processing. Contact us today to find the perfect autoclave solution for your application!

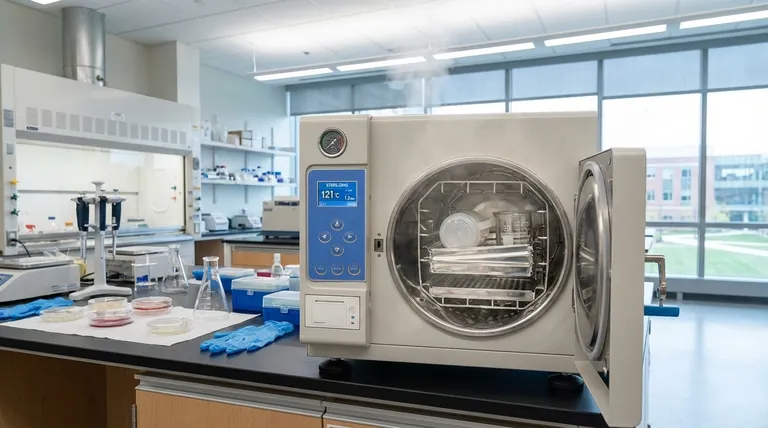

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- How long does an autoclave work? Understand Cycle Times for Effective Sterilization

- What are the disadvantages of autoclave in microbiology? Key Limitations for Lab Safety

- What are examples of autoclave in microbiology? Essential Sterilization for Lab Safety & Accuracy

- What does an autoclave do to microorganisms? How It Achieves Sterilization with Steam