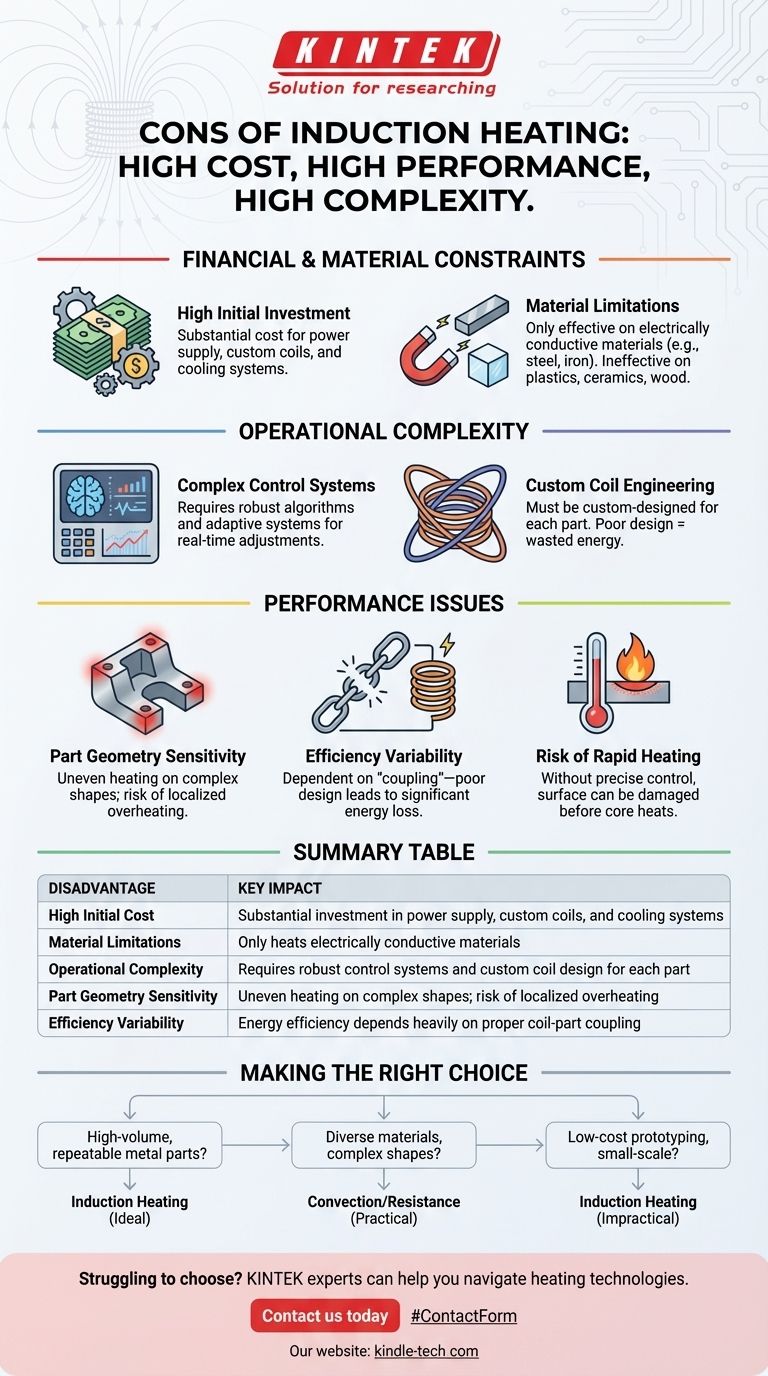

The primary disadvantages of induction heating are its high initial equipment cost, its limitation to only electrically conductive materials, and its significant operational complexity. While incredibly fast and precise, the technology requires specialized engineering for coil design and sophisticated control systems to function effectively.

Induction heating offers unparalleled speed and precision, but this performance is not universally applicable. The core trade-off is accepting a high initial investment and significant engineering overhead in exchange for highly controlled, rapid heating in very specific applications.

The Challenge of Control and Complexity

One of the most significant hurdles in adopting induction heating is the technical expertise required to run it properly. It is not a simple "plug-and-play" solution.

The Need for Robust Control Systems

Induction power supplies require robust and complex control algorithms. These systems must constantly adapt to different loads and operating points to deliver consistent heat.

As noted in research, this is especially challenging in systems with multiple coils or varying part types, often requiring adaptive algorithms for real-time adjustments.

Custom Coil Engineering

The induction coil, which generates the magnetic field, is the heart of the system and must be custom-designed for the specific part being heated.

The shape, size, and distance of the coil relative to the workpiece are critical for efficiency. A poorly designed or mismatched coil will result in uneven heating and wasted energy.

Financial and Material Constraints

Beyond the operational complexity, there are fundamental financial and physical limitations that define where induction heating is a viable option.

High Initial Capital Investment

The initial cost of an induction heating system is substantial. This includes the high-frequency power supply, the custom-fabricated coils, and often a dedicated water-cooling system to manage the heat generated in the coil itself.

Limitations on Workpiece Material

Induction heating works by inducing an electrical current within the object itself. Therefore, it is only effective on electrically conductive materials, primarily ferrous metals like steel and iron.

It cannot directly heat non-conductive materials such as plastics, glass, ceramics, or wood, making it unsuitable for a wide range of applications.

Dependence on Part Geometry

The efficiency and evenness of heating are highly dependent on the shape of the part. Complex geometries with sharp corners, holes, or varying thicknesses can be very challenging to heat uniformly.

These features can cause the magnetic field to concentrate, leading to localized overheating and potential damage or warping of the workpiece.

Understanding the Trade-offs

The advertised benefits of induction heating often come with hidden conditions that must be carefully considered.

Efficiency Isn't Guaranteed

While induction heating can be highly energy-efficient, this is entirely dependent on the "coupling" – how effectively the magnetic field transfers energy to the part.

Poor coupling due to an improper coil design or incorrect positioning leads to significant energy loss, negating one of the technology's key selling points.

The Risk of Rapid Heating

The ability to heat objects in seconds is a major advantage. However, this speed can also be a liability.

Without precise control, the surface of a part can easily be overheated and damaged before the core reaches the desired temperature. This demands a level of process control far greater than that required for slower methods like furnace heating.

Making the Right Choice for Your Goal

Evaluating induction heating requires matching its unique profile of high cost and high performance to your specific needs.

- If your primary focus is high-volume, repeatable manufacturing of simple metal parts: The initial investment is often justified by the unmatched speed, consistency, and control.

- If your primary focus is heating diverse materials or parts with complex shapes: A more flexible technology like a convection oven or resistance furnace will likely be more practical and cost-effective.

- If your primary focus is low-cost prototyping or small-scale production: The high capital cost and specialized engineering make induction heating an impractical choice.

Ultimately, choosing induction heating is a strategic decision that trades flexibility and low upfront cost for unparalleled speed and precision within a narrow set of ideal conditions.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Initial Cost | Substantial investment in power supply, custom coils, and cooling systems |

| Material Limitations | Only heats electrically conductive materials (e.g., metals) |

| Operational Complexity | Requires robust control systems and custom coil design for each part |

| Part Geometry Sensitivity | Uneven heating on complex shapes; risk of localized overheating |

| Efficiency Variability | Energy efficiency depends heavily on proper coil-part coupling |

Struggling to choose the right heating method for your lab or production line? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the complexities of heating technologies—from induction to furnaces and ovens—to find the most efficient and cost-effective solution for your specific materials and applications. Contact us today for a personalized consultation and let us help you optimize your thermal processing!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- What effect does a high-vacuum environment in a hot-press furnace have on Mo-Na alloys? Achieve Pure Microstructures

- How does pressure control in vacuum hot press sintering equipment contribute to the densification of SiCp/6061 composites?

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- What specific processing conditions does a vacuum hot pressing furnace provide for the sintering of FeCrAl composites?

- What are the advantages of a vacuum hot-press furnace? Superior Bonding for Diamond/Aluminum Composites