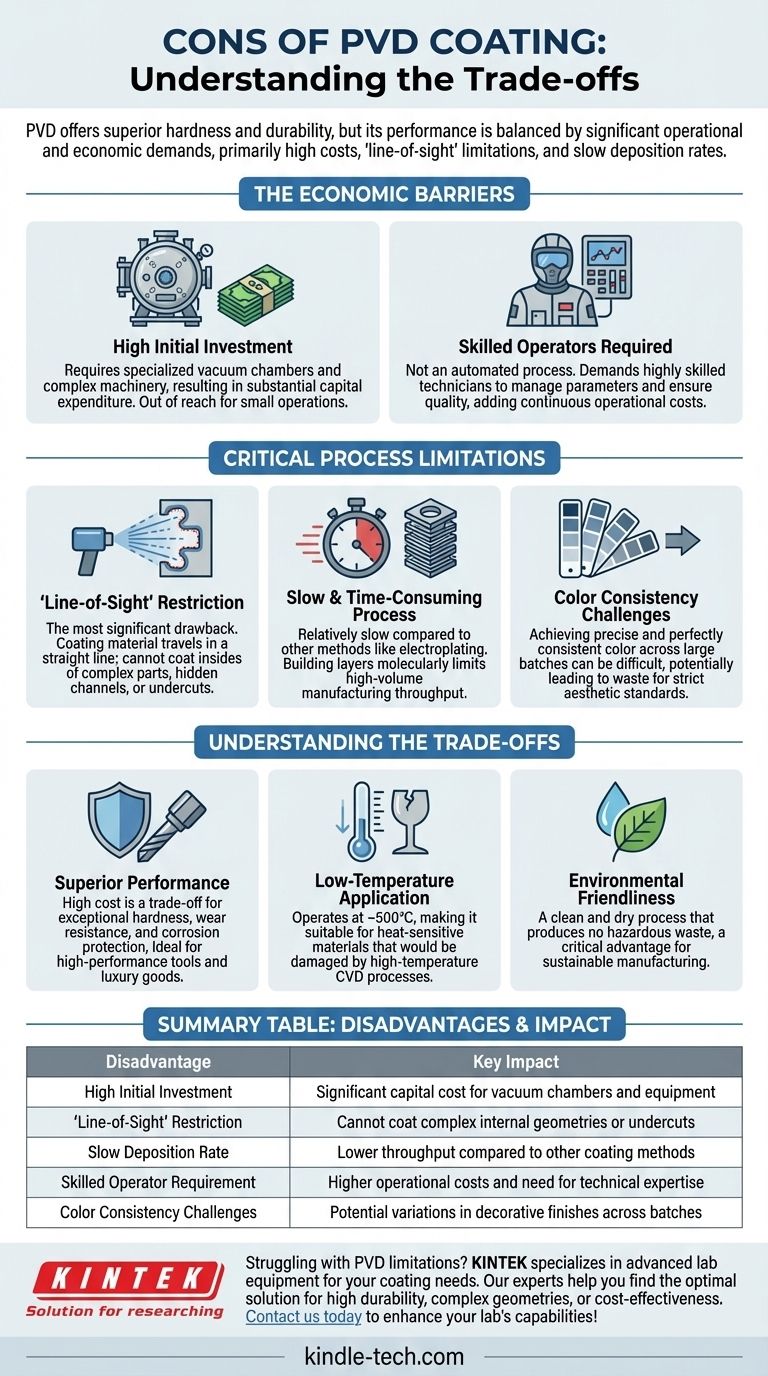

While Physical Vapor Deposition (PVD) offers exceptional surface hardness and durability, its primary disadvantages are not in its performance but in its operational and economic demands. The process is defined by high costs due to specialized equipment, a fundamental "line-of-sight" application restriction, and relatively slow deposition rates that can impact production timelines.

The core challenge of PVD is not a question of quality, but one of practicality. Its significant benefits are balanced by high costs and process limitations that make it unsuitable for every application, particularly those involving complex geometries or tight budgets.

The Economic Barriers to PVD

The financial investment required for PVD is a primary consideration. These costs stem from both the initial setup and the ongoing operational requirements.

High Initial Investment

PVD coating requires a highly controlled environment, necessitating a large vacuum chamber and other complex machinery. This specialized equipment represents a significant capital expenditure, placing it out of reach for smaller operations or low-cost projects.

Requirement for Skilled Operators

The process is not automated in a simple "press-and-play" manner. It demands a high level of expertise to manage the vacuum, control the deposition parameters, and ensure consistent quality. The need for highly skilled technicians adds a substantial and continuous operational cost.

Critical Process Limitations

Beyond cost, the physics of the PVD process itself imposes constraints that engineers and designers must account for.

The 'Line-of-Sight' Restriction

The most significant technical drawback of PVD is that it is a "line-of-sight" process. This means the coating material travels in a straight line from the source to the target workpiece.

Any surface that is not directly visible to the source material will not be coated. This makes PVD fundamentally unsuitable for coating the insides of complex parts, hidden channels, or intricate geometries with undercuts.

Slow and Time-Consuming Process

Compared to other coating methods like electroplating, the PVD process is relatively slow. Building up the coating layer by layer at a molecular level is a time-consuming endeavor, which can limit throughput for high-volume manufacturing.

Challenges in Color Consistency

While PVD is used for decorative finishes, achieving a precise and perfectly consistent color across large batches can be challenging. Slight variations in process parameters can alter the final appearance, potentially leading to material wastage if strict aesthetic standards are required.

Understanding the Trade-offs

The disadvantages of PVD must be weighed against its significant advantages. These limitations are often the necessary price for achieving a unique set of benefits.

Performance vs. Practicality

The high cost and process limitations are trade-offs for achieving a coating with superior hardness, wear resistance, and corrosion protection. For high-performance tools or luxury goods, these benefits can easily justify the expense.

Low-Temperature Application

PVD operates at lower temperatures (around 500°C) compared to alternatives like Chemical Vapor Deposition (CVD). This makes it the ideal choice for coating heat-sensitive materials that would be damaged or distorted by higher-temperature processes.

Environmental Friendliness

The PVD process is clean and dry, producing no hazardous waste. This environmental advantage is a critical factor for companies focused on sustainable manufacturing, often justifying the higher operational complexity.

Is PVD the Right Choice for Your Application?

Choosing the right coating method requires aligning the process capabilities with your project's specific goals.

- If your primary focus is maximum hardness and durability on simple shapes: PVD is a leading contender, provided the budget can accommodate the higher cost.

- If your primary focus is coating complex internal geometries or hidden surfaces: PVD's line-of-sight nature makes it unsuitable; you must consider other methods.

- If your primary focus is high-volume, low-cost production: The slow deposition rate and high operational costs of PVD may make it economically impractical.

- If your primary focus is coating a heat-sensitive substrate: PVD's low-temperature application gives it a distinct advantage over high-temperature alternatives.

Understanding these inherent limitations is the key to successfully leveraging PVD's powerful capabilities where they matter most.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Initial Investment | Significant capital cost for vacuum chambers and equipment |

| Line-of-Sight Restriction | Cannot coat complex internal geometries or undercuts |

| Slow Deposition Rate | Lower throughput compared to other coating methods |

| Skilled Operator Requirement | Higher operational costs and need for technical expertise |

| Color Consistency Challenges | Potential variations in decorative finishes across batches |

Struggling with PVD coating limitations for your lab equipment? KINTEK specializes in providing advanced lab equipment and consumables tailored to your specific coating and surface treatment needs. Our experts can help you navigate the trade-offs between PVD and other methods to find the optimal solution for your application—whether you require high durability, complex geometry coating, or cost-effective production. Contact us today to discuss how we can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures