The correct procedure for post-experiment handling of an acrylic electrolytic cell involves a systematic sequence of de-energizing the system, safely managing chemical waste, and performing a tiered cleaning process. This ensures operator safety, environmental compliance, and the longevity and accuracy of the equipment for future experiments.

Proper cleaning is not simply a janitorial task; it is a critical scientific step that prevents cross-contamination, preserves the integrity of your equipment, and ensures the validity of your future results. The core principle is to match the cleaning method to the type of residue, from simple rinsing to targeted chemical treatment.

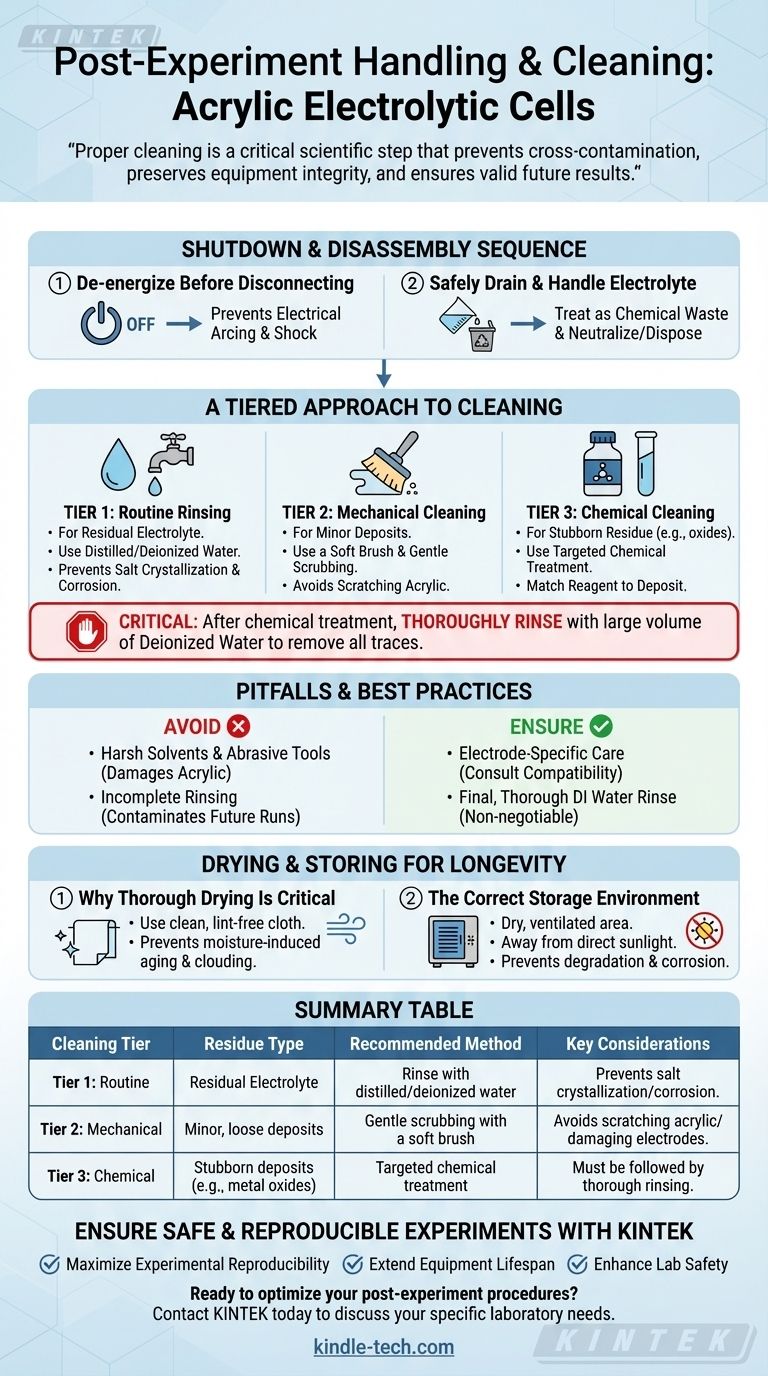

The Shutdown and Disassembly Sequence

The first priority after an experiment is to bring the system to a safe, inert state. Rushing this process introduces unnecessary risks to both the operator and the equipment.

De-energize Before Disconnecting

Always turn off the power supply before disconnecting the electrolytic cell's leads. This fundamental safety step prevents the possibility of electrical arcing, which can damage the equipment and pose a significant shock hazard.

Safely Drain and Handle Electrolyte

Once de-energized, carefully drain the electrolyte from the cell. This solution must be treated as chemical waste. It should be transferred to a designated, properly labeled waste container for neutralization, recycling, or disposal according to your institution's environmental and safety regulations.

A Tiered Approach to Cleaning

Cleaning is not a one-size-fits-all process. The appropriate method depends entirely on the nature of the residue left behind after the experiment.

Tier 1: Routine Rinsing

For most experiments, a thorough rinse is sufficient. Use distilled or deionized water to flush the cell body, electrodes, and any holders. This removes residual electrolyte, preventing salt crystallization and corrosion during storage.

Tier 2: Mechanical Cleaning for Minor Deposits

If a simple rinse leaves behind visible deposits, gentle mechanical cleaning is the next step. Use a soft brush to carefully scrub the electrodes and the inside of the cell. This is often effective for loosely adhered products or precipitates.

Tier 3: Chemical Cleaning for Stubborn Residue

When dealing with stubborn deposits like metal oxides (e.g., rust), a targeted chemical cleaning is necessary. The key is to select a reagent that dissolves the deposit without damaging the cell or electrodes. For example, dilute hydrochloric acid can remove iron oxides.

After chemical treatment, it is absolutely critical to rinse the components with a large volume of deionized water to remove all traces of the cleaning agent.

Understanding the Trade-offs and Pitfalls

Improper cleaning can cause more harm than good. Understanding the limitations and risks associated with each method is crucial for preserving your equipment.

The Risk of Damaging the Acrylic

Acrylic is susceptible to damage from both harsh chemicals and physical abrasion. Avoid using strong organic solvents and never use abrasive pads or hard-bristled brushes, as they can scratch or craze the acrylic, compromising its structural integrity and transparency.

Electrode-Specific Cleaning Needs

Different electrode materials require different care. While a base metal electrode might be cleaned mechanically, a precious metal electrode (like platinum) may require soaking in a specific solution, such as dilute nitric acid, to remove deposits without damaging the expensive material. Always verify the correct procedure for your specific electrodes.

The Hazard of Incomplete Rinsing

Any chemical residue left from the cleaning process will become a contaminant in your next experiment. This can alter reaction chemistry, poison catalysts, and ultimately invalidate your results. A final, thorough rinse with deionized water is non-negotiable.

Drying and Storing for Longevity

The final step ensures the cell is preserved correctly for future use.

Why Thorough Drying Is Critical

After a final rinse, dry the cell body with a clean, soft, lint-free cloth. Electrodes and other components should also be dried completely. Proper drying prevents the slow, moisture-induced aging and potential clouding of the acrylic material.

The Correct Storage Environment

Store the clean, dry electrolytic cell and its components in a dry, ventilated area away from direct sunlight. This protects the acrylic from degradation and prevents any corrosion on metallic parts.

Making the Right Choice for Your Goal

Your post-experiment protocol should align with your primary objective.

- If your primary focus is ensuring experimental reproducibility: Your priority is meticulous cleaning to eliminate any chance of cross-contamination from a previous run.

- If your primary focus is equipment longevity: Your priority is gentle handling, avoiding harsh chemicals or abrasive tools, and ensuring proper drying and storage.

- If your primary focus is lab safety and compliance: Your priority is de-energizing the system first and adhering strictly to all chemical waste disposal protocols.

This disciplined approach transforms routine cleanup into a critical step that safeguards your equipment and your research integrity.

Summary Table:

| Cleaning Tier | Residue Type | Recommended Method | Key Considerations |

|---|---|---|---|

| Tier 1: Routine | Residual Electrolyte | Rinse with distilled/deionized water | Prevents salt crystallization and corrosion. |

| Tier 2: Mechanical | Minor, loose deposits | Gentle scrubbing with a soft brush | Avoids scratching acrylic or damaging electrodes. |

| Tier 3: Chemical | Stubborn deposits (e.g., metal oxides) | Targeted chemical treatment (e.g., dilute HCl for rust) | Must be followed by thorough rinsing to prevent contamination. |

Ensure Your Lab's Electrolytic Experiments are Safe and Reproducible

Proper handling and cleaning are fundamental to laboratory success. KINTEK specializes in providing high-quality lab equipment and consumables, including durable electrolytic cells designed for easy maintenance and long-term reliability.

Let us help you achieve your goals:

- Maximize Experimental Reproducibility: Our equipment supports meticulous cleaning protocols to eliminate cross-contamination.

- Extend Equipment Lifespan: We offer products and guidance on gentle, effective cleaning practices.

- Enhance Lab Safety: Our solutions are designed with safety and compliance in mind.

Ready to optimize your post-experiment procedures? Contact KINTEK today to discuss your specific laboratory needs and discover how our reliable equipment can support your research integrity.

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What is the structure of an H-type exchangeable membrane electrolytic cell? A Guide to Precise Electrochemical Separation

- What optical features does the H-type electrolytic cell have? Precision Quartz Windows for Photoelectrochemistry