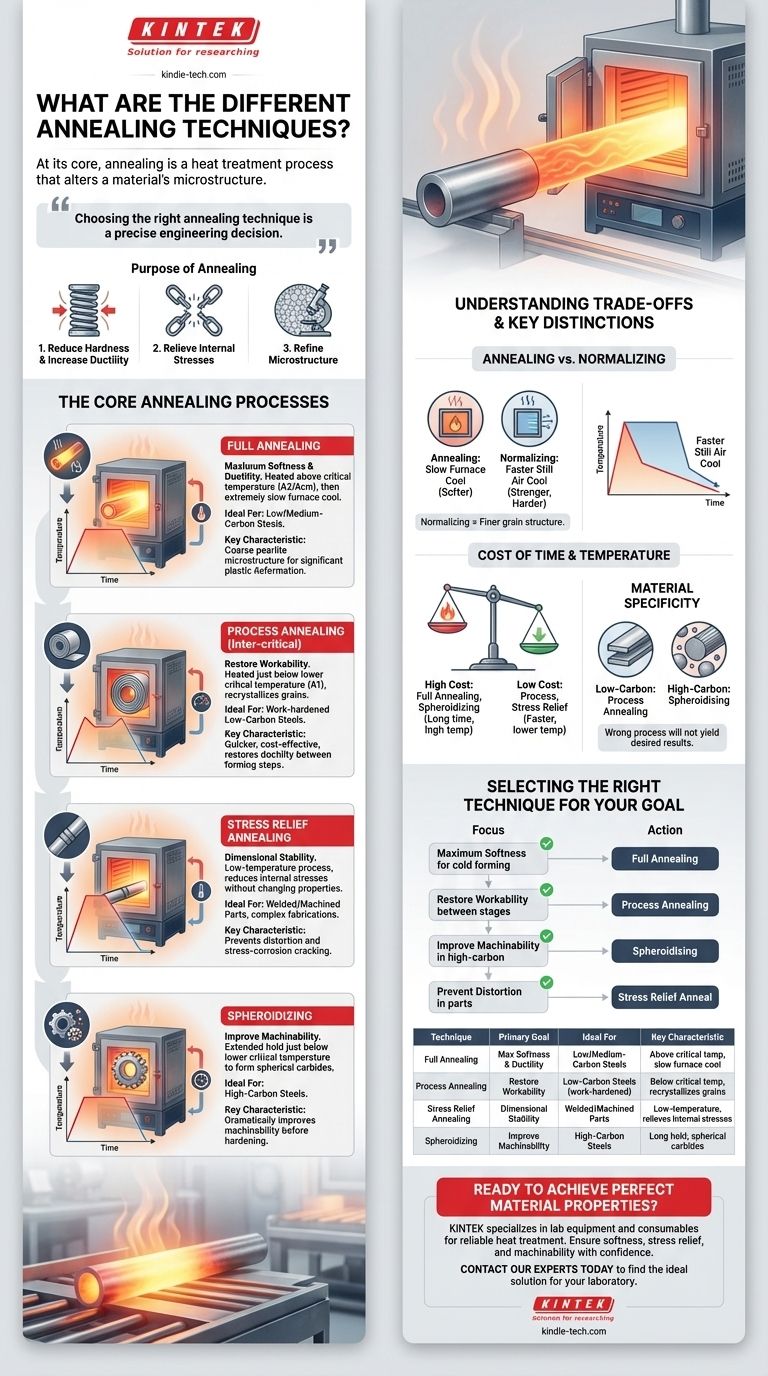

At its core, annealing is a heat treatment process that alters a material's microstructure to achieve specific, desirable properties. The primary techniques include full annealing, process annealing, stress relief annealing, and spheroidizing, each differentiated by the temperatures used and the rate of cooling, which in turn dictates the final state of the material.

Choosing the right annealing technique is not about simply heating and cooling a metal. It is a precise engineering decision that matches a specific thermal cycle to a material's composition and its intended application, whether that is to maximize softness, improve machinability, or ensure dimensional stability.

The Purpose of Annealing: A Quick Refresher

Before diving into specific techniques, it's crucial to understand the fundamental goals of any annealing process. These treatments are designed to "reset" a material's properties in a controlled way.

Reducing Hardness and Increasing Ductility

The most common reason to anneal is to soften a material. This process reverses the effects of hardening treatments or cold working, making the material more ductile and less brittle. This is essential for subsequent manufacturing steps like cold forming, stamping, or bending.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or heavy machining introduce significant internal stresses into a material. If left untreated, these stresses can lead to premature failure or dimensional distortion over time. Annealing provides a way to relieve these stresses without significantly changing the material's core mechanical properties.

Refining the Microstructure

Annealing can produce a more uniform and homogeneous internal grain structure. This refinement eliminates inconsistencies within the metal, leading to more predictable and reliable performance in service.

The Core Annealing Processes

While all annealing involves heating, holding, and cooling, the specific parameters of that cycle define the technique and its outcome.

Full Annealing

This is the most comprehensive and often most energy-intensive annealing process. The material, typically low or medium-carbon steel, is heated above its upper critical temperature (A3 or Acm), held long enough for its structure to fully transform into austenite, and then cooled extremely slowly in the furnace.

The result is a very soft, ductile material with a coarse pearlite microstructure, ideal for parts that will undergo significant plastic deformation.

Process Annealing (Inter-critical Annealing)

This technique is used to restore ductility in a work-hardened part between manufacturing steps. Unlike full annealing, the material is heated to a temperature just below its lower critical temperature (A1).

Because no phase change occurs, it is a quicker and less expensive process. It allows the material's grain structure to recrystallize, relieving the stresses from cold working and preparing it for further forming operations. It is primarily used for low-carbon steels.

Stress Relief Annealing

This is a low-temperature process designed specifically to reduce internal stresses with minimal impact on the material's hardness and structure. The part is heated to a temperature well below the lower critical point and held long enough for the residual stresses to relax.

This is critical for complex welded fabrications or precision-machined components to ensure they remain dimensionally stable and are not prone to stress-corrosion cracking.

Spheroidizing

This specialized process is applied almost exclusively to high-carbon steels to achieve maximum softness and machinability. The material is held for an extended period (often many hours) at a temperature just below the lower critical point.

This long hold time causes the hard iron carbide layers (cementite) in the microstructure to break apart and form small, spherical globules within the soft ferrite matrix. This spheroidized structure dramatically improves the steel's machinability before a final hardening operation.

Understanding the Trade-offs and Key Distinctions

Choosing an annealing process involves balancing the desired properties against time, cost, and material constraints.

Annealing vs. Normalizing: A Critical Difference

Normalizing is often discussed alongside annealing but produces a different result. Like full annealing, it involves heating above the upper critical temperature. However, the cooling is done in still air, which is faster than furnace cooling.

This faster cooling creates a finer, more uniform grain structure, resulting in a material that is slightly harder and stronger than a fully annealed one. Normalizing is often chosen when a combination of good ductility and moderate strength is required.

The Cost of Time and Temperature

Full annealing and spheroidizing are the most expensive processes due to high temperatures and extremely long cycle times, consuming significant furnace time and energy.

Process annealing and stress relief annealing are much faster and more economical because they operate at lower temperatures, making them suitable for high-volume production where full softening is not required.

Material Specificity Is Non-Negotiable

The effectiveness of each technique is highly dependent on the material's carbon content. Process annealing is ideal for low-carbon steels, while spheroidizing is only relevant for high-carbon steels. Applying the wrong process will not yield the desired results.

Selecting the Right Technique for Your Goal

Your choice must be driven by the final properties your component requires. A clear understanding of your goal will point you directly to the correct process.

- If your primary focus is maximum softness for severe cold forming: Use full annealing for low-to-medium carbon steels to achieve the highest possible ductility.

- If your primary focus is restoring workability between manufacturing stages: Use process annealing as a cost-effective method to soften work-hardened low-carbon steels.

- If your primary focus is improving machinability in high-carbon steel: Spheroidizing is the necessary technique to prepare the material for cutting operations.

- If your primary focus is preventing distortion in a welded or machined part: Apply a low-temperature stress relief anneal to ensure long-term dimensional stability.

Ultimately, a precise understanding of these techniques empowers you to dictate the final properties of a material to perfectly match its service requirements.

Summary Table:

| Annealing Technique | Primary Goal | Ideal For | Key Characteristic |

|---|---|---|---|

| Full Annealing | Maximum Softness & Ductility | Low/Medium-Carbon Steels | Heated above critical temperature, slow furnace cool |

| Process Annealing | Restore Workability | Low-Carbon Steels (work-hardened) | Heated below critical temperature, recrystallizes grains |

| Stress Relief Annealing | Dimensional Stability | Welded/Machined Parts | Low-temperature, relieves internal stresses |

| Spheroidizing | Improve Machinability | High-Carbon Steels | Long hold time to form spherical carbides |

Ready to achieve the perfect material properties for your application?

The right annealing process is critical for performance, but it requires precise thermal control. KINTEK specializes in the lab equipment and consumables needed for reliable heat treatment processes. Our expertise helps laboratories and manufacturers ensure material softness, stress relief, and machinability with confidence.

Let's discuss your specific needs. Contact our experts today to find the ideal solution for your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness