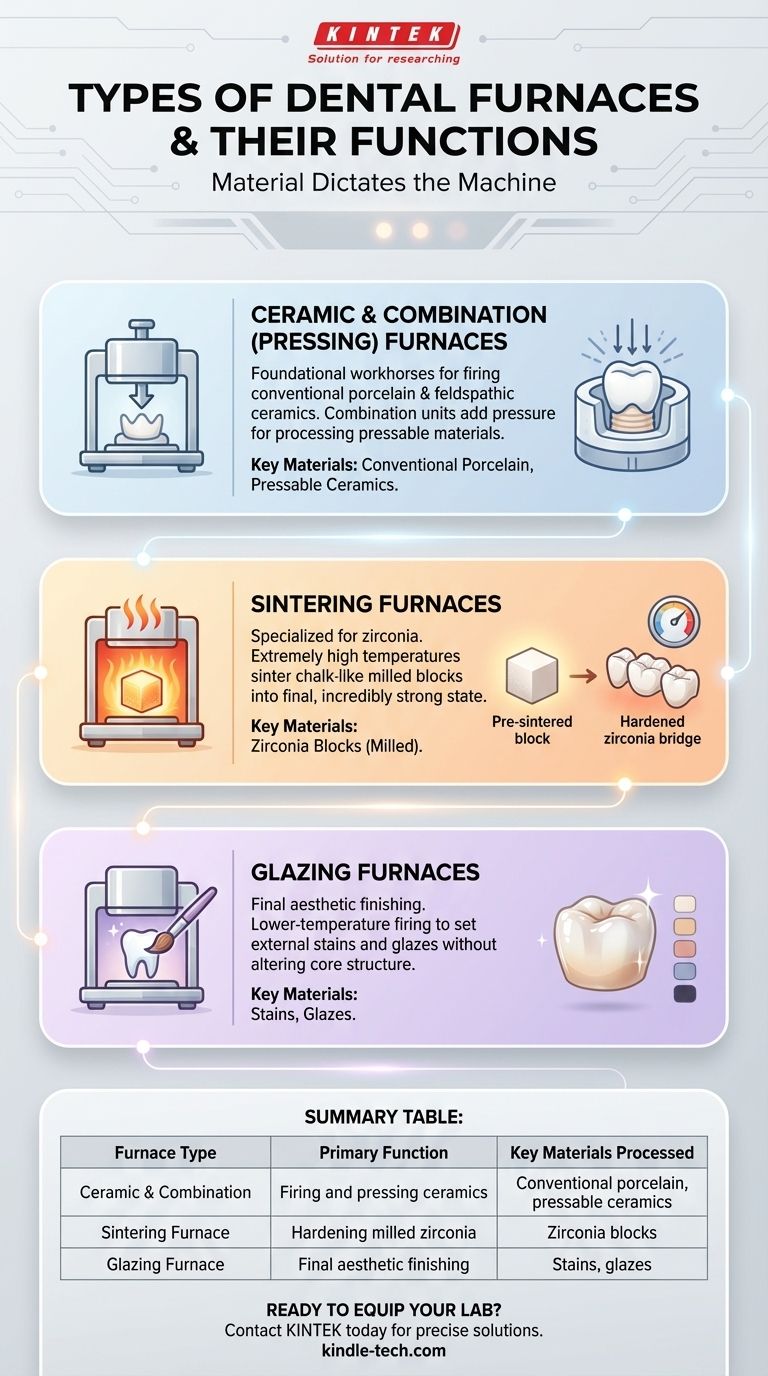

At the heart of every ceramic dental restoration is a furnace designed for a specific task. The primary types of dental furnaces are defined by the materials they process and the stage of fabrication they support: Ceramic and Combination Furnaces for conventional and pressable materials, Sintering Furnaces for high-strength zirconia, and Glazing Furnaces for final aesthetic finishing.

The critical takeaway is that the type of dental furnace required is not a matter of preference but is dictated entirely by the specific dental material being used. Each furnace is engineered to achieve the unique temperature, pressure, and atmospheric conditions a material like zirconia or pressable ceramic needs to reach its final, durable state.

The Role of the Furnace in Dental Restorations

A dental furnace, or oven, is the essential laboratory equipment used to transform ceramic materials into their hardened, final form for restorations like crowns, bridges, and veneers.

From Milled Block to Final Prosthesis

These devices use precisely controlled high temperatures, and in some cases pressure, to alter the physical properties of the ceramic. This process, often called firing or sintering, is what gives the final restoration its required strength and stability.

Precision Through Modern Technology

Modern dental furnaces are microprocessor-controlled for exceptional accuracy. They feature programmable memory systems that can store hundreds of unique firing programs, ensuring repeatable and reliable results with temperature control often accurate to within a single degree (±1°C).

A Breakdown of Furnace Types by Function

While all dental furnaces use heat, their specific designs are tailored for different materials and processes. Understanding these differences is key to any dental lab's workflow.

Ceramic & Combination (Pressing) Furnaces

These are the foundational workhorses found in nearly every dental laboratory. A standard ceramic furnace is used for firing conventional porcelain and feldspathic ceramics.

A combination furnace adds the ability to apply pressure during the heating cycle. This pressure is essential for processing pressable ceramic materials, making these combination units highly versatile.

Sintering Furnaces

Sintering furnaces are specialized units designed for one primary purpose: processing zirconia. After a zirconia restoration is milled from a block, it exists in a soft, chalk-like state.

This furnace must reach extremely high temperatures—far higher than a standard ceramic furnace—to sinter the material, causing it to shrink and harden into its final, incredibly strong state. They are essential for any lab or milling center that produces zirconia restorations in-house.

Glazing Furnaces

The final step in creating a lifelike restoration is applying external stains and glazes to match the patient's natural tooth shade.

A glazing furnace is used for this finishing stage. It runs a lower-temperature firing cycle designed specifically to set these glazes onto the surface of the restoration without altering the core structure of the ceramic.

Understanding the Practical Considerations

Choosing and utilizing the right furnace directly impacts lab efficiency, capability, and the quality of the final product. The decision is less about which furnace is "best" and more about which is necessary for the work being performed.

Material Dictates the Machine

The single most important factor is the material. You cannot properly process zirconia in a combination furnace, nor can you press ceramics in a sintering furnace. The material requirements are absolute and dictate the necessary equipment.

Lab Specialization Defines the Need

A full-service lab that handles all types of materials will need multiple types of furnaces. However, a lab that outsources its zirconia milling has no need for a large sintering furnace. This is why combination furnaces are ubiquitous, while sintering furnaces are more common in specialized milling centers.

Making the Right Choice for Your Goal

Your lab's specific services and material choices will determine your equipment needs.

- If your primary focus is on conventional porcelain and pressable ceramics: A high-quality combination furnace is the most critical and versatile piece of equipment for your operations.

- If your primary focus is on producing in-house zirconia restorations: A dedicated sintering furnace is non-negotiable to achieve the required material properties.

- If your primary focus is on high-volume aesthetic finishing: A separate glazing furnace can streamline your workflow, freeing up larger furnaces for more intensive cycles.

Ultimately, understanding these distinct furnace functions is the key to matching your equipment precisely to the materials and outcomes your work demands.

Summary Table:

| Furnace Type | Primary Function | Key Materials Processed |

|---|---|---|

| Ceramic & Combination | Firing and pressing ceramics | Conventional porcelain, pressable ceramics |

| Sintering Furnace | Hardening milled zirconia | Zirconia blocks |

| Glazing Furnace | Final aesthetic finishing | Stains, glazes |

Ready to equip your lab with the right dental furnace?

At KINTEK, we specialize in providing the precise lab equipment dental professionals need to achieve superior results. Whether you're processing zirconia, pressing ceramics, or applying final glazes, our range of high-performance furnaces delivers the accuracy and reliability your workflow demands.

Let our experts help you select the perfect furnace to match your materials and enhance your lab's capabilities. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges